Researchers have succeeded in growing a uniform 2D layer of silk protein fragments on a van der Waals substrate – in this case, graphene – for the first time. The feat should prove important for developing silk-based electronics, which have been limited until now because of the difficulty in controlling the inherent disorder of the fibrillar silk architecture.

Silk is a protein-based material that humans have been using for over 5000 years. In recent years, researchers have been looking to exploit one of its two main components, silk fibroin (which is made up of protein fragments), in electronic and bioelectronic applications. This is because it can self-assemble into a range of fibril-based architectures that boast excellent mechanical and optical properties. Indeed, devices in which silk fibroin films are interfaced with van der Waals solids, metals or oxides appear to be particularly promising for making next-generation thin-film transistors, memory transistors (or memristors), human–machine interfaces and sensors.

There is a problem, however, in that silk cannot be used in its natural form for such devices because its fibres are arranged in a disordered, tangled fashion. This means it cannot uniformly or accurately modulate electronic signals.

Controlling natural disorder

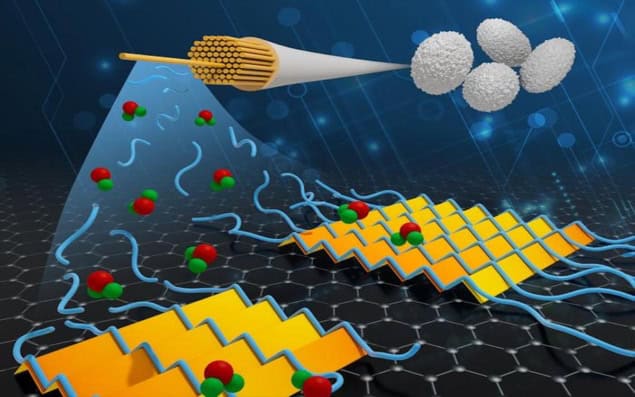

A team of researchers, led by materials scientist and engineer James De Yoreo of the PNNL and the University of Washington, has now found a way to control this disorder. In their work, the researchers grew highly organized 2D films of silk fibroins on graphene, a highly conducting sheet of carbon just one atom thick.

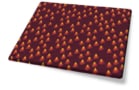

Using atomic force microscopy, nano-Fourier transform infrared spectroscopy and molecular dynamics calculations, the researchers observed that the films consist of stable lamellae of silk fibroin molecules that have the same structure as the nano-crystallites of natural silk. The fibroins pack in precise parallel beta-sheets – a common protein shape found in nature – on this substrate.

Thanks to scanning Kelvin probe measurements, De Yoreo and colleagues also found that the films modulate the electric potential of the graphene substrate’s surface.

The researchers say that they took advantage of the inherent interactions of the silk molecules with the substrate and its crystallinity to force the silk molecules to assemble into a crystalline layer at the interface between the two materials. They then regulated the concentration of the aqueous solution in which the silk proteins had been dissolved to limit the number of silk layers that form. In this way, they were able to assemble single monolayers, bilayers or much thicker multilayers.

Uniform properties

Since the material is highly ordered, its properties are uniform, says De Yereo. What’s more, because of the strong intermolecular interactions in the beta-sheet arrangement and the strong interactions with the substrate, it is highly stable. “In its pure state, it can regulate the surface potential of the underlying conductive substrate, but there are techniques for doping silk to introduce both optical and electronic properties that can greatly expand its useful properties,” he explains.

Silk hard drive stores optical data

The researchers hope their results will help in the development of 2D bioelectronic devices that exploit natural silk-based layers chemically modified to provide different electronic functions. They also plan to use their starting material to create purely synthetic silk-like layers assembled out of artificial, sequence-defined polymers that mimic the amino acid sequence of the silk molecule. “In particular, we see potential for using these materials in memristors, for computing based on neural networks,” De Yereo tells Physics World. “These are networks that could allow computers to mimic how the brain functions.”

It is important to note that the system developed in this work is nontoxic and water-based, which is crucial for biocompatibility, adds the study’s lead author Chenyang Shi.

The research is detailed in Science Advances.