Researchers at the University of Toledo have developed a smart injectable material for use in bone implants (Materials 11 1258). The new material incorporates varying concentrations of barium titanate (BT) in calcium phosphate (CaP) cements. The “smart” capabilities of this material come from the piezoelectric properties of BT: with applied pressure, the material develops surface charges. This electromechanical property has been shown to play a valuable role in healing fractured bone and integrating implant materials into the surrounding bone.

Natural bone exhibits piezoelectric behaviour – making this a valuable feature to incorporate into materials for bone implants. Including BT in bone cement forms a novel material: one that provides the beneficial piezoelectric properties directly to the bone defect site to promote fracture healing. However, as with all implant materials, this new bone cement must be methodically characterized before it can be successfully applied to orthopaedic defects.

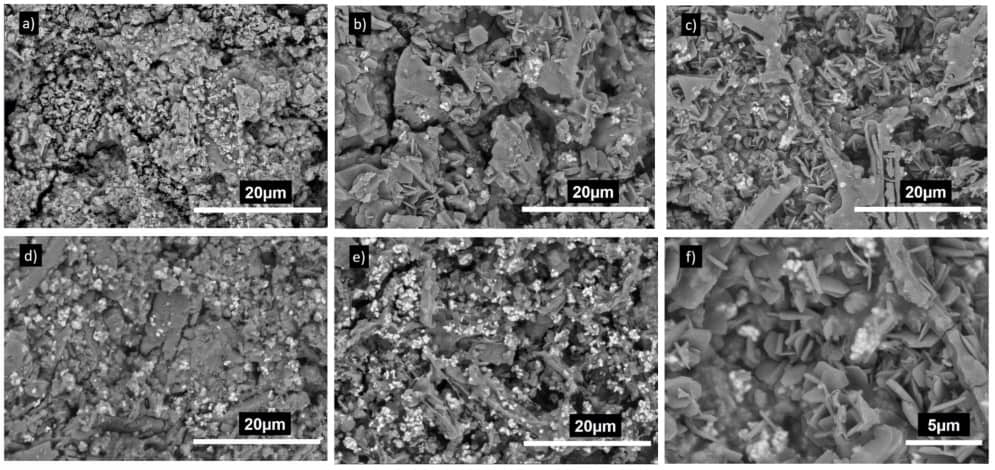

The team synthesized smart CaP bone cement mixtures with 0, 20 and 40% BT (by weight). They then thoroughly characterized each formulation for its setting time, compressive strength, injectability, washout resistance, biodegradation and biocompatibility – all important factors for an implantable bone material.

In order to inject the material into bone defects, it is important to have sufficient handling and working time before the cement sets. For this reason, the team optimized the cement composition to achieve a setting time of about 15 minutes. Once set, it is critical that the compressive strength of the cement is comparable to that of natural bone, in order for it to serve as a suitable bone graft. The team aimed for a compressive strength of at least that of spongy bone (10 MPa). The smart CaP cement exhibited strengths higher than 15 MPa, demonstrating its suitability for orthopaedic applications.

The smart CaP cement formulations showed good injectability for up to 5-6 minutes after mixing. When placed in a saliva-like solution, all formulations showed excellent washout resistance, i.e., they did not deteriorate or disperse in solution. Remarkably, the team observed no disintegration even after 24 hours.

Though it is ideal for the implant material to stay intact while setting, it is also important that the material slowly degrades over time while natural bone grows to fill in the defect. The 20% BT formulation showed favourable degradation rates, but the 40% BT composition showed significantly less degradation over seven days, as determined by weight loss, making it a less desirable implant composition.

The toxicity of an implant material to the surrounding cells in the body is of utmost importance. The team tested the biocompatibility of the smart CaP cements using osteoblastic (bone) cells. After 24 hours, cell numbers were comparable on all formulations. However, after 72 hours, there was a significant decrease in cell numbers on the 40% BT formulation, indicating lower biocompatibility. More favourably, the 20% BT formulation showed enhanced cell proliferation after 72 hours. After five days, all cells on the smart CaP cement remained viable, indicating that the formulations were not toxic to the cells.

Overall, the smart CaP compositions were bioactive, biocompatible and biodegradable. All behaved similarly regarding setting time, mechanical strength, bioactivity, injectability and washout resistance. Based on biocompatibility and biodegradability, the most favourable smart CaP cement composition was 20% BT. Combined with its piezoelectric properties from the incorporated BT, this novel material is a possible candidate for a new generation of smart biodegradable CaP bone cements for orthopaedic applications that enhance fracture healing.