A new type of self-healing liquid metal composite could be used to make soft, recyclable, electronic circuits. These composites do not break even when punctured and can be repeatedly stretched without losing their electrical conductivity.

Most electronic circuits are made from semiconductors such as silicon or gallium arsenide shaped into nanometric-sized structures that are soldered together via wires. These structures are rigid and opaque, however, and cannot be easily incorporated into soft electronics applications. Such applications include smart textiles, biomedical devices that need to be integrated with the body, patches worn on the skin to monitor health and robotic skin. All require materials that are robust to wear and tear, are stretchable and remain electrically conductive even when damaged. Ideally, they need to be recyclable, too.

Replacing inflexible circuits

Led by Michael Bartlett, researchers from Virginia Tech in the US have now proposed replacing conventional inflexible circuits with micron-sized, electrically-conducting liquid metal droplets dispersed in a soft, protective elastomer called styrene-isoprene-styrene (SIS), with polybutadiene (PBD) added as a plasticizer.

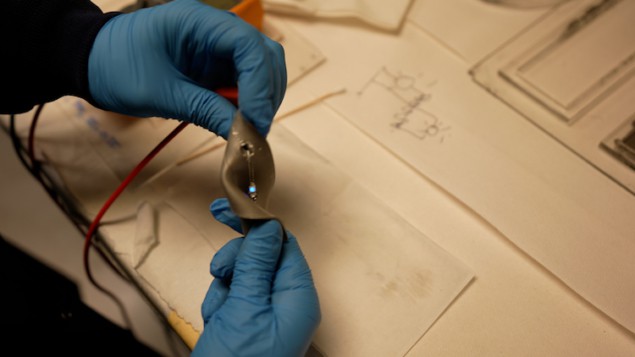

Bartlett and colleagues used a technique known as embossing to fabricate connected liquid metal networks with high electrical conductivities. This approach creates connections between the droplets that allows them to reconfigure (self-heal) even if they become damaged, meaning that they continue to function. For example, a circuit made from the composite will continue to transfer power even if a hole is punched in it. This is because the droplets make new connections around the hole, maintaining the flow of current. In comparison, a hole in a traditional wire would cut the electrical connection completely. The polymer network can also be stretched to over 10 times its original length without suffering much change in its electrical conductivity.

Reprocess, reuse, recycle

Another advantage of the new approach is that if the circuit needs to be reconfigured, the droplets are easy to break apart by using a solvent to “erase” them. Their constituents can then be used to form new conductive channels, thanks to the thermoplastic nature of the SIS copolymer matrix and the liquid nature of the metal.

The researchers, who report their work in Communications Materials, showed that they could reconfigure a circuit in this way by rapidly dissolving the composite sheets in toluene in a shear mixer to make a SIS/PBD/toluene solution. As the liquid metal droplets dispersed in the solution are similar to those in the initial pristine composite, the solution can then be re-cast into films with mechanical proprieties like the originals. The recycled samples are electrically insulating after casting, meaning that all the previous electrical connections have been deleted.

Self-healing composite could make resilient robot skin

Bartlett says that he and his colleagues are “excited with their progress and envision these materials as key components for emerging soft technologies”. “This work gets closer to creating soft circuitry that could survive in a variety of real-world applications,” he says.

Spurred on by their findings, the researchers now plan to integrate their stretchable circuity into wearable devices and soft robotics. “Systems in which soft components are integrated with traditional microchips provide some great opportunities, but also some significant challenges,” Bartlett says. “Merging these technologies presents a challenge in design, optimization, and manufacturing, but it could also open up new device possibilities that do not exist today,” he tells Physics World.