A polymer transistor that retains its electrical properties when stretched repeatedly has been developed by US researchers, who demonstrate its potential with a basic finger-mounted device. The device could have a number of different applications including systems that monitor a patient’s blood glucose levels and other physiological quantities.

The “internet of things”, in which numerous everyday objects in the world around us collect and exchange data, is a developing paradigm in electronics. This could include sensors mounted on the skin, which could continuously monitor the blood glucose levels of diabetics. Attaching computer chips to flexible, stretchable surfaces such as skin is a challenge because silicon is rigid and brittle. The quest for stretchable electronic devices has led researchers to use tiny silicon “chiplets” encased within stretchable matrices, producing electronic materials that can change shape even if the silicon itself does not.

“During the stretching, only the interconnects can dissipate the strain,” explains Sihong Wang of Stanford University in California. “That limits the density of devices they can achieve in a circuit.”

Stretchable alternative

The ideal solution is a stretchable alternative to silicon, and the leading candidates are conjugated polymers, in which overlapping electron orbitals create a delocalized electronic network that can conduct electricity. While these organic semiconductors are softer than traditional inorganic semiconductors, their stretchability generally remains poor – and designing the molecules often involves trading carrier mobility for stretchability. Researchers have compromised by blending high-mobility, brittle conjugated polymers with ductile, less conductive ones.

Now, Sihong Wang, Jie Xu and colleagues at Stanford and elsewhere have modified this approach. Previous methods have formed the polymer nanofibres first, allowing them to crystallize and fixing their properties in advance. If the nanofibres are later embedded in a softer polymer, it allows the composite to absorb more strain, but the conductive nanofibres themselves remain brittle.

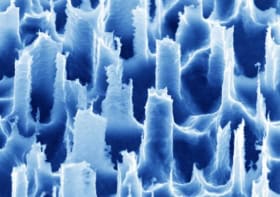

In the new work, however, the researchers dissolved both types of polymer in a solution, which was then cast into films. When the films were processed, thermodynamics drove the solution to separate into two different phases, forming long, thin nanofibres of conductive polymer embedded in the soft elastomer. As the conductive nanofibres crystallized inside the confined space, they experienced the finite-size effect. This means that polymers confined into nanoscale spaces retain higher chain mobility because the growth of large crystalline regions is restricted. “The conjugated polymer here is growing inside these nanostructures,” explains Xu. “That’s why the crystallinity is decreased and the ductility is improved.”

Stretching the composite films to twice their length left their carrier mobility unaffected. Under the same treatment, the mobility of a pure conjugated polymer film dropped by a factor of up to 1000 and the material developed significant cracks.

Twisting and poking

The researchers produced fully stretchable transistors using networks of carbon nanotubes as electrodes and films of the low-mobility polymer as the dielectric. When they stretched the transistor to twice its length in the direction of charge transport, the on current of the transistor did drop, but simply because of the increase in the channel length. The device recovered its properties extremely well after stretching: it could be stretched by 25% of its length more than 1000 times without showing a significant change in its electrical properties. It could also survive repeated twisting and poking with a sharp object – provided a hole was not made.

The researchers wired up one of their transistors as a device that regulates the power supply to an LED. They attached it to a human finger and found that bending the finger did not affect the device operation. Creating more complex circuitry will require ways to pattern their film efficiently and precisely, and the team is now developing these.

Iain McCulloch of Imperial College London and King Abdullah University of Science and Technology in Saudi Arabia, who was not involved in the work, believes it could be an important development in polymer electronics: “Traditionally, organic semiconducting materials for transistor applications have found it quite difficult to replace the incumbent technology,” he says. “To identify an application that requires a unique attribute of organic electronics is always exciting, and I think that, in stretchable and wearable electronics, you can really see that an organic material could have distinct advantages.”

Brendan O’Connor of North Carolina State University in the US is pleased with the electrical stability of the films after repeated stretching: “That in itself is a pretty big accomplishment,” he says. He describes the production of fully stretchable transistors as “a pretty significant advance that only a few groups in the world can really do effectively.”

The transistors are described in Science.