A new and simple “dipping” technique that can significantly improve the performance of supercapacitors has been developed by researchers at Stanford University in the US. The method, dubbed “conductive wrapping”, could be applied to a range of electrode materials. It might even be used to improve next-generation electrodes made from sulphur, lithium manganese phosphate and silicon for use in lithium-ion batteries.

Supercapacitors – more accurately known as electric double-layer or electrochemical capacitors – can store much more charge than a conventional capacitor. This is thanks to a double layer that forms at the electrolyte–electrode interface of such devices when a voltage is applied.

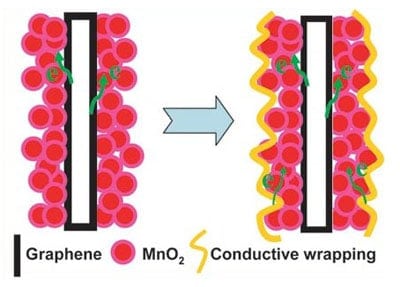

The conductive-wrapping technique can further increase the capacitance of a supercapacitor by boosting the conductivity of the electrodes – which enhances the device’s ability to store charge. Developed by Zhenan Bao, Yi Cui and colleagues, the process involves dipping a composite electrode made of graphene and manganese oxide into a solution containing either carbon nanotubes (CNTs) or a conductive polymer. The CNTs or polymer coat the electrode and boost its ability to store charge by more than 20% for the CNT coating and 45% for the polymer.

Higher specific capacitance

The specific capacitance obtained by the researchers (about 380 F/g) is comparable to other manganese-oxide-based electrodes, which typically have specific capacitances of between 250–400 F/g. However, the hybrid electrodes also show good “rate capability” – which means that they maintain their high capacitance at high charging and discharging rates. This is in contrast to conventional metal-oxide-based electrodes, which usually have poor rate capability because they have low electronic and ionic conductivity.

As a result, the new electrodes can also be used for more than 3000 charge–discharge cycles while retaining more than 95% of their capacitance. When combined with the fact that the electrodes have a much higher specific capacitance than existing commercial carbon-based supercapacitors (150–250 F/g), the conductive-wrapping technique looks promising.

Large-scale energy-storage applications

“The hybrid electrode system we have developed shows promise for large-scale energy-storage applications,” says team member Guihua Yu. “From the perspective of materials selection, both graphene and MnO2 are attractive electrode materials given that both carbon and manganese are cheap and abundant. From a processing point of view, our coating method is solution-based and easy to scale up.”

The researchers are now busy working on improving the performance of the electrodes in lithium-ion batteries using the method. “Our novel approach could be applied to a wide range of energy-storage electrode materials that have high energy density but that show limited performance because of their insulating nature,” says Yu.

The results are reported in Nano Letters.