Claimed to be highly realistic and elephant-friendly, a new alternative to ivory has been developed by researchers in Austria. Led by Jürgen Stampfl at the Vienna University of Technology, the team used stereolithography to 3D print a replica material called “Digory”, which they claim closely mimics both the mechanical and optical properties of real ivory. Their approach could make it far easier for conservators to restore historical ivory artefacts.

Renowned for its aesthetic appearance, durability, and ease of sculpting, ivory has been used for centuries to create practical and artistic objects. However, its use has extracted a terrible toll on elephant populations and its global trade was banned completely in 1989. Today, conservators use synthetic replica materials to restore damaged ivory artefacts – yet none of these are fully able to recreate characteristics like the colour, translucency, and surface gloss of the real thing.

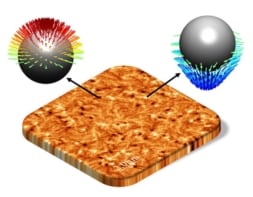

Stamfl’s team aimed to recreate these properties using stereolithography: a 3D printing technique that uses heated, light-sensitive resins to construct polymer materials layer by layer. Previously, the researchers used this approach to create ceramic materials, and even artificial teeth.

UV polymerization

To make artificial ivory they used a dimethacrylic resin in a liquid state, in which they embedded fine particles of calcium phosphate. On exposure to an ultraviolet laser, molecules in the resin polymerize to form long, rigid chains, resulting in a solid material with calcium phosphate particles trapped inside. By fine-tuning the fractional volume of these particles, the team could adjust the translucency, density, and hardness of the material to make it resemble ivory. The result was an advanced new synthetic material, which they named Digory.

3D printing makes bionic mushroom

In collaboration with the Archdiocese of Vienna, Stamfl and colleagues used their technique to restore a 17th century casket from a local church. The artefact had been decorated with ivory ornaments, but some of these had been lost over the centuries. The team’s additive manufacturing approach enabled them to recreate the complex and delicate features of the ornaments in digital constructions. After printing, they then treated their replicas with pigments to match the colour of the original ornaments. With further staining and polishing, the appearance of the Digory material was barely distinguishable from the genuine ivory on the casket.

Where previous restoration processes relied on time-consuming and error-prone carving techniques, the team’s approach will now allow conservators to print Digory replicas in just a few hours, with no material waste. Overall, the project clearly demonstrates the ability of stereolithography to reproduce the many desirable properties of ivory, without posing any further threat to wild elephants.

The research is described in Applied Materials Today.