The ISIS Neutron and Muon Source has just installed a suite of new instruments at its second target station and is looking to bring in more users from industry

“We build new instruments when we come up with new areas of science that we can explore with neutrons,” explains Chris Frost as he shows Physics World around the ISIS Neutron and Muon Source in Oxfordshire, UK. With new instruments being built and others being upgraded to meet the growing demands of industry and academia, it is apparent that there are lots of new ideas around. Indeed, some parts of the ISIS complex still look like a building site. “It’s a good thing,” adds Frost, who is industry liaison manager and instrument scientist at ISIS. “It means that someone is investing in building something here. We are regularly building new instruments or modifying the ones we already have.”

Having produced its first neutrons in 1984, ISIS is still Europe’s only pulsed source of neutrons. Today, it employs around 360 staff and is visited by more than 3000 users from over 30 different countries each year. The facility’s first target station – with 20 instruments – has been remarkably successful, with more than 10,000 research papers having been written off the back of work carried out there. In 2003 the facility won support for a £145m ($224m) second target station that began producing its first neutrons in 2008. Initially containing seven instruments – including three reflectometers, one spectrometer and three diffractometers – the facility has just completed a £30m upgrade that will see the addition of four instruments, just six short of full capacity.

We started anticipating the needs of the users over the next 10–20 years, so now there are many areas of science into which neutrons are providing key insights

ISIS is the only neutron source in the world running two target stations and the second station marks a shift in focus for ISIS from traditional areas such as magnetism and superconductivity to soft condensed matter, which includes the study of polymers and biological materials. While the first target station provided higher-energy, shorter-wavelength neutrons with a pulse rate of 50 Hz, the second target station will provide lower-energy, longer-wavelength neutrons with a pulse rate of 10 Hz – perfect for studying biological samples. “When we started at ISIS, many people were using neutrons to study magnetic systems,” says Frost. “We then started anticipating the needs of the users over the next 10–20 years, so now there are many areas of science into which neutrons are providing key insights.”

Industrial use

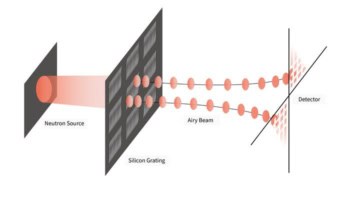

Neutrons are powerful probes that can provide detailed information on the structure of a range of materials from low-temperature superconductors to thin films of biological samples. Unlike X-rays, neutrons penetrate deep into a sample, revealing its bulk properties rather than just the material’s surface characteristics. As well as being electrically neutral, neutrons also have a magnetic moment, which means that they interact with magnetic materials to reveal details about their magnetic structure and spin dynamics.

Frost’s responsibility is as ISIS instrument scientist for ChipIR, which is one of the four new instruments on the second target station. Its role is to examine the damage that can be done to materials by high-energy neutrons and other particles created when cosmic rays interact with the Earth’s atmosphere. These particles can, in particular, affect chips and other electronic systems in aircraft and cars – not only by damaging the electronics, but also by wiping a device’s memory. ChipIR will be able to test components with a measuring time of just one hour – equivalent to exposing microchips to high-energy neutrons over hundreds of years of flying time in an aircraft. “ChipIR will help industry understand where the vulnerabilities are to help mitigate those problems in ways that are as cost-effective as possible,” says Frost.

Next to ChipIR is the IMAT neutron imaging and diffraction instrument. IMAT will be used in a broad range of areas such as aerospace, civil engineering, earth sciences and cultural heritage – for example, by measuring the strain in engineering components or the mechanics of cracks in steel. As for the two other new instruments – LARMOR and ZOOM – they are both small-angle neutron-scattering (SANS) instruments that can be used to study magnetism as well as polymers and biological samples. Rob Dalgliesh, an instrument scientist, says that LARMOR “has the potential to be one of the best instruments of its type in the world”. He adds that the instrument will be able to study many samples in 10–15 minutes or less using SANS and will provide a platform for new and exciting types of measurement using multiple techniques.

An industry angle to ISIS is not, however, new. It was back in the mid-1990s, at the first target station, that ISIS built the first purpose-built instrument for industry. ENGIN, which was upgraded to ENGIN-X in 2003, measures strain within a crystalline material assessing the internal structure of an aeroplane wing, for example. With instruments such as ChipIR and IMAT, ISIS is now keen to to build on this collaboration with industry. “Neutrons can solve near-market problems, be it stress in train wheels and bolts that are used in aircraft or providing better understanding of strain in underwater pipes,” says Frost. “Neutrons are a very effective tool for the non-destructive analysis of industrial materials.”

Users from industry, however, will have to pay for their beamtime if they want to keep the results to themselves rather than publish them in a journal. According to ISIS director Robert McGreevy, industrial participation will be an additional revenue stream for the lab with around 90% of the time on ChipIR being used by industry. Indeed, McGreevy adds that the next instrument to be built at the second target station will likely be another engineering instrument. “Neutron scattering can only be done at big facilities, so industrial engagement is increasing,” he says. “Industry use ISIS to improve their products and processes, and this benefits both the companies and the UK economy.”

Back to the future

While the second target station has taken all the focus in recent years, now some of that is changing back towards the first target station. There are plans to upgrade its target and moderator assembly – the design of which is around 25 years old – based on what has been learned during the construction of the second target station. According to McGreevy, that should result in a three- or four-fold improvement in terms of the neutron flux being delivered to each instrument. “Some instruments might see gains of more than this given the reduction in the background,” says McGreevy. “It would be for a relatively modest cost of around £15m – about the price of two instruments – so it would be a good investment.”

Further ahead, McGreevy adds that there could even be scope for a third target station. “Look at the economics and it is clear,” says McGreevy. “The accelerator is expensive, so the more science you can do with it, the more value for money you get.” Indeed, that optimism for expanding ISIS is not threatened by the upcoming European Spallation Source (ESS), which is being built in Lund, Sweden and will generate its first neutrons in 2019. The UK is a 10% partner in the project where it is building two beamlines. “Our futures are inextricably interwoven – ISIS will not become an obsolete facility,” says McGreevy. “If ISIS was not here, the ESS would not be useful for the UK because you would have no users to use it.”

As we near the end of our tour around both target stations at ISIS, Frost talks about what he sees as the strength of the facility and why it has been not only been successful for the UK, but a pioneering source worldwide. “Instruments scientists here do not just serve the academic community, they are actively part of that academic community,” he says. “We never stop thinking about what you can do next. We have been here for 30 years and we expect to be here for another 30 years.”

How neutrons are made at ISIS

ISIS produces neutrons by firing high-energy beams of protons at a tungsten target. First, negative hydrogen ions are produced in an ion source and accelerated to 665 keV before being accelerated in the linear accelerator to 70 MeV. They are then stripped of their electrons by a 0.3 µm-thick aluminium-oxide foil to leave a beam of protons that are then accelerated to 800 MeV via a 163 m-circumference synchrotron. Four out of five of the proton pulses kicked out of the synchrotron are sent to the first target station while the fifth pulse is sent to the second target station.

The protons from each beam then hit a tantalum-clad tungsten target where each proton produces 15–20 neutrons with around 2 × 1016 neutrons being produced each second. The proton beam energy deposited in the target on the first target station is 160 kW, and on the second target station is 40 kW. The neutrons are finally slowed down to useable energies by moderators such as water (316 K), methane (100 K) and liquid hydrogen (20 K). Neutrons are then channelled along beamlines to neutron instruments surrounding the targets.