A team of researchers at the University of Florida in the US have devised a new “printing-then-gelation” fabrication technique that exploits a granular microgel as a support material for liquid 3D structures that are later solidified. The novel two-step approach, which the team described last year in the IOP journal Biofabrication, can produce a much wider range of soft biomaterials than is possible with conventional printing techniques (Biofabrication 8 025016). Physics World spoke to Yong Huang, the lead researcher, to find out more.

How does the new “printing-then-gelation” method work?

During conventional “gelation-while-printing” processes, the printed material is gelled or solidified in situ to retain the shape that is formed during printing. This approach requires bioinks to be cross-linkable in a short period of time, which limits the types of biomaterials that can ultimately be printed.

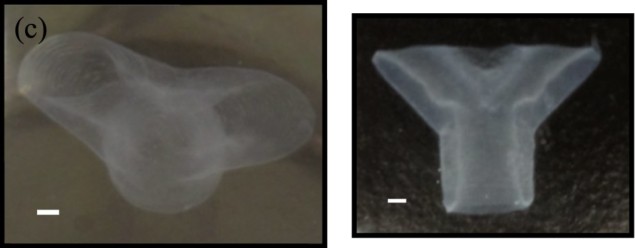

Our alternative “printing-then-gelation” method involves first extruding a liquid hydrogel precursor (an alginate solution) through a nozzle tip that is located within a fluid support material (Carbopol granular microgel). This process creates liquid three-dimensional structures in a support bath, which can then be gelled afterwards. The technique allows us to successfully print a variety of bioinks directly – even those that are difficult to print – and allows free-form fabrication of complex structures without gravitational constraints.

How have you developed the technique, and what challenges still remain?

Since the initial demonstration of the technique, we have also shown that we can print various soft or biological structures from these difficult-to-print materials using two-step or even multi-step gelation processes (MRS Bulletin doi.org/10.1557/mrs.2017.164). There is still a problem to overcome here though, since the granular gel support we use is sensitive to the ionic strength of the fluid transport material, and so is limited to certain fluids. We are now looking into alternative support materials so that the new approach might be more widely implemented.

How does your work fit in with your wider research programme?

Many researchers view this free-form fabrication of soft structures as a critical step towards the holy grail of organ printing – that is, the on-demand design and fabrication of 3D human organ constructs for implantation and regenerative medicine. Our techniques are one step towards this goal. Material extrusion in particular is a platform 3D printing method that can be used to produce engineered tissue. High-performance support materials are also obviously invaluable here for facilitating the printing processes.

What feedback have you received from the research community?

Many research groups have contacted us following the publication of our Biofabrication paper to discuss the feasibility of the printing-then-gelation methodology and to see whether they could use the approach in their projects to make complex 3D biological constructs.

What other breakthroughs have you made since last year?

Our technique relies on innovative support materials, like Carbopol, to effectively stabilize the liquid structure during fabrication until it is ready to be gelled. Ideally, such materials should flow freely when subject to an external force that is higher than their yield stress, but they should also maintain their form and cease to flow when subject to weaker forces.

Although the granular gel is an excellent support for some types of bioink, it is limited to the types of bioinks it can work with, so we have been looking at other potential support materials. One specific material that comes to mind here is our new nanoclay system, in which nanoclay is used both as a support bath and as an internal scaffold material.

What are the next stages in your research?

Our priority is to continue to look for new, more versatile yield-stress support fluids. We will also be investigating the fundamental processes at play behind 3D bioprinting and the physical properties and behaviour of bioprinted structures. For example, how do they mature to form tissues and what mechanical properties do they have? These studies will be important, in particular, for vascular tissue substitution.

- Read our special collection “Frontiers in biofabrication”to learn more about the latest advances in tissue engineering. This article is one of a series of reports highlighting high-impact research published in the IOP Publishing journal Biofabrication.