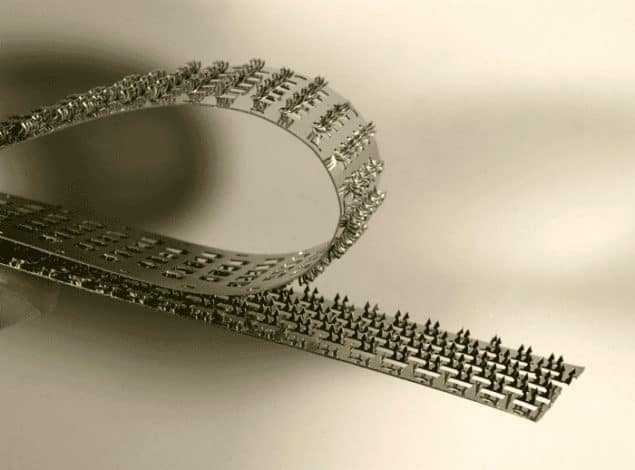

Researchers in Germany have created a new type of fastener system made from steel that may be useful in a range of settings, including hospitals and the aviation industry. Borrowing its design from nature, the new material comprises a series of hooks in the shape of birds’ heads that feed into a series of tiny loops along a perforated strip.

Velcro was invented more than 60 years ago by the Swiss inventor George de Mestral, who drew inspiration from the difficulty he experienced when removing burrs from the fur of his dog. The product name originates from the French for velvet (velours) and hook (crochet) on account of the underlying mechanism – a piece of fabric covered in tiny hooks fastens to a second piece of fabric covered in tiny hairy loops.

The real beauty of this “wonder material” is that it can seal with a relatively tight grip but still be released with minimal effort. For this reason it has found a plethora of applications from a shoe-lace substitute to bandages in hospitals. It is even used in some industrial applications to hold machinery together. Although originally made using cotton, hook-and-loop fasteners are now typically fabricated using nylon and polyester on account of their strong grip and resistance to wear and tear.

Sticky situation

The trouble, however, with these fasteners is that their gripping mechanism tends to break down when exposed to harsh conditions such as high temperatures and aggressive cleaning chemicals. This limitation leads to problems in industrial and applications.

Now, a research team at the Technical University of Munich, working in conjunction with industrial firms based in Germany, may have found a solution to this problem. They have created a new hook-and-loop fastener using steel, chosen for its high resistance to mechanical loads and chemical corrosion. Steel is also highly ductile, meaning that it can deform significantly under high stresses without fracturing and breaking the grip.

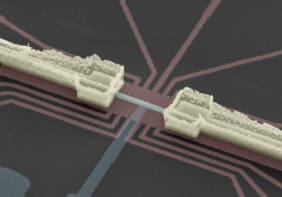

In developing the fastener, which is dubbed “Metaklett“, meaning “metal burr”, Josef Mair and his colleagues tested a range of different hook designs. After combining laboratory testing with computer simulations, the researchers settled on two specific designs, both of which are resistant to chemicals and remain fastened up to 800 °C.

Follow the birds

The first hook mechanism is based on the shape of a flamingo, which provides a more stable locking mechanism than the hooks in conventional fasteners. This type of Metaklett is designed for its pure strength because, depending on the direction of the applied force, the fastener can withstand a load of up to 35 tonnes per square metre.

The second type of hook is called an “Entenkopf”, because it resembles a “duck’s head”, and this design is closer to synthetic Velcro. While this design cannot support the same sort of load, it has the advantage of flexibility because it can remain fastened while subjected to stresses from a variety of directions. Mair and his team are also working on a third design – the “hybrid” model – which combines the strength of the flamingo with the flexibility of the duck.

Since the beginning of this project, the researchers have been working with industry with the aim of creating bespoke metal fasteners for a range of applications. “I can imagine Metaklett being used in hospitals – for example, as a means of fastening curtains that doesn’t get damaged when exposed to hospital cleaning,” said Mair.

The automotive and aviation industries may also benefit from the new advance. “Things can get very hot in the automotive sector. A car parked in direct sunlight can reach temperatures of 80 °C, and temperatures of several hundred degrees can arise around the exhaust manifold,” said Mair. The researcher told physicsworld.com that he can envisage his new metal fastener being used both as a shield covering exhaust pipes and as a means of holding panels together in planes.

Mair and his colleagues are continuing to test their designs with the assistance of their industrial partners: Victor Reinz, Hölzel Stanz und Feinwerktechnik GmbH & Co and Koenig Verbindungstechnik GmbH.