When Michael Mertin stepped into the role of president and chief executive officer at Jenoptik AG in July 2007 his first priority was to restructure and strengthen the organization. Today, with the restructure complete, Jenoptik is a streamlined company with five divisions that is predicting group sales in excess of €550m in 2008, despite tough economic conditions. Jacqueline Hewett caught up with Mertin just after the publication of Jenoptik’s half-year report for January to June 2008 to find out about its new business model, growth markets and its recent move into India.

Why did you restructure Jenoptik?

Jenoptik was founded after the reunification of Germany, with the intention of liquidating the company a couple of years later. At that time, Jenoptik had no markets and no customers, just technology. However, former Jenoptik president Lothar Späth wanted to turn the technology into a success story.

To do this, he bought sales channels through the acquisition of several private companies in the western part of Germany that were already established in the market, with the idea of leveraging the technology out of Jenoptik. He also structured the business into legal entities to be more flexible for partnerships with large customers (e.g. Trumpf or Hilti). Only the fittest legal entities survived the first 10 years. The end result was a financial holding with a large number of different legal entities being active in 40 market segments.

By forming the business into five large divisions, we have been able to achieve the market strength and cost structure that is required to be an international player in the optics and photonics market. This also reduces the complexity of the group.

We considered three points when restructuring into five divisions. First, what are our markets, who are our customers and how are our competitors structured? Second, what is our internal value chain and how is it organized? And finally, technology. We had to move Jenoptik from being a technology-driven company to a customer-driven company leveraging on technology. The end result is a company that is today organized into five market segments that we call divisions: optical systems; lasers and material processing; industrial metrology; traffic solutions; and defence and civil systems.

All of the individual companies that make up Jenoptik are now grouped into one of these five divisions. This is clear for customers and suppliers, and we have strength under one banner. It is better to tell a customer, or even a competitor, that I am a part of a $250m optical business, which is driven by Jenoptik, one of the biggest optoelectronics companies in the world.

What are your key growth markets?

In such a large over-arching optoelectronics company like Jenoptik you need at least two legs: one to stand on and one to kick yourself with. One must be reliable with constant growth and cash flow, especially if on the kicking leg you have a cyclical market such as lithography.

This is the reason why we are highly committed to our defence business for example, which follows totally different market cycles than the typical optical business. We don’t expect the same growth potential over the years like we have typically (at least in the good years) from lasers and optics, but it is a stable business with sustained growth potential.

We need this constant cash flow to be prepared in a downturn, for example the downturn in lithography. We need the cash flow and stability from these reliable long-term businesses to grow our potential in the more volatile markets of lasers and high-end optics. The high growth potential is not just in laser sources, but in laser applications. Knowing the process, the source and having the ability to build the proper machine around it. This is one of our growth stories today.

How important is photovoltaics?

Photovoltaics is becoming an increasingly important sector for Jenoptik. Coming from competencies that we already had in-house, we decided to enter the field of production technology for solar cells last year. We knew that we could leverage existing technology and focus it on laser-based machines for the solar industry.

We are predicting double-digit million euro sales for fiscal year 2008 supplying international photovoltaic companies with laser-based machines for the production of solar cells. Our available laser sources will provide us with an additional competitive advantage in the coming years.

Are you active in the thin-film solar cell and crystalline silicon markets?

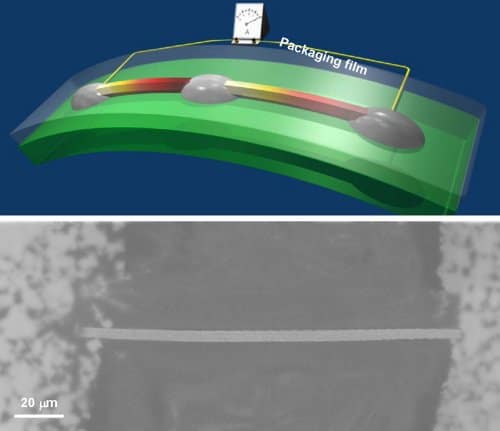

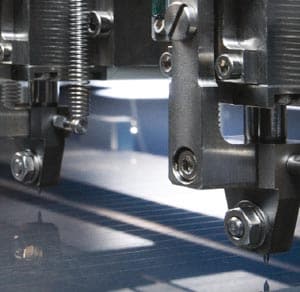

Yes. We have laser-based technologies for edge deletion as well as laser and mechanical-based processes for structuring thin-film solar cells. The mechanical and thermal stability of the machines themselves plays an important role in addition to the laser processes.

If you need parallel lines 5 µm apart over more than 1.5 m, you can imagine that this is a big challenge. We have experience from the semiconductor industry and automation competence that we were able to apply to thin-film solar cells.

For silicon wafers, we have developed a process to dice not just along the typical crystalline axis, but in a freeform approach. This is becoming more important as silicon wafers become thinner. The thickness of solar wafers is currently 180–200 µm and this will decrease to 120 or 130 µm in the next 3–4 years.

We perform laser-induced local heating along the line that you want to dice and then cool the silicon down extremely quickly, which induces stress. There will be a crack along this stress line. The crucial point is that it leaves a perfect edge. This process does not waste material and you can be very precise. There is no thermal influence on the wafer and there are no unwanted particles on the surface. The risk of having a total failure or crack through the entire wafer is zero.

Will you apply your silicon solar cell process to other industries?

The semiconductor industry also requires a machine to dice silicon wafers. Jenoptik won the “Best of West” award presented by the global semiconductor association SEMI this year for its process. In the field of laser materials processing, our Jenoptik Votan G machine is suitable for the mass production of brittle materials. This machine uses our thermal laser beam separation process.

We can also use this approach for the cover glass in the solar industry. If you dice glass by our process, you have a perfect edge and the stability against bending is up to three times higher than having it classically cut. You can also dice thinner glasses. Another application is the glass used in the electronics industry for displays.

What are your long-term markets?

A good example is the aerospace industry and our Star Sensors. These are essentially digital optical instruments that take pictures of the stars every tenth of a second and compare these images with an integrated star catalogue. When you perform data processing, you can be highly accurate in your 3D position in space. The trust in our technology has grown with time to the extent that we won Boeing’s best supplier award for our Star Sensors in 2007.

Based on this technology and also our laser competence, we developed automated docking sensors for rendezvous manoeuvres between vehicles in space. Our first docking sensors were successfully tested on the US space shuttle in 1997. These are automated sensors that support unmanned vehicles docking with the International Space Station (ISS). We now deliver these sensors to European and Japanese space missions in order to supply the ISS.

This is not a growth industry like solar but it is good to have this high-tech industry onboard. It is a stable and viable long-term business. Making it successful now is very good for the overall position of the company. This allows us to take risks as and when we have to.

Can you tell me more about your traffic security business?

Not a lot of people know that we are active in the area of speed enforcement and red-light enforcement. For us, this falls under traffic security and also public–private partnerships in traffic security and enforcement systems.

In western European countries, fatal accidents are decreasing due to safer cars and the enforcement of traffic laws. However, if you look at countries in Central America, northern Africa or in the Asia–Pacific region, there are more and more young educated people being killed or injured by traffic accidents. It really becomes an economic problem for these countries.

One option is public–private partnerships. The country wants companies to invest in the technology and bring a new level of security to the country. As well as being the leader for hardware, we are now stepping into solution-providing models for public–private partnerships.

This is new business for us. Leveraging on our leading position in hardware and now going one step forward on the value chain to our customer (a country, region or city) for these enforcement systems. This is a big growth option for our company but we have to put a lot of money into building the infrastructure.

How important is the Indian market in your plans for the future?

India is one of the most important, maybe the most important, market for high-tech in Asia–Pacific. Our industrial metrology division is present in India to serve the automotive industry.

The newly introduced tiny Indian cars that are priced at around €2500 still need 5 litres of fuel to travel 100 km and this is just too much. A car in this price range must be cheap in terms of the energy it is using and this is strongly driven by metrology: the better the manufacture of the engine, the better the pollution values and the better the fuel consumption. A more efficient engine easily gives a significant reduction in fuel consumption.

We are looking forward to substantial growth in India. Our globally leading position in optical-based measurement will help Indian automotive suppliers to improve their quality.

• This article originally appeared in the October 2008 issue of Optics & Laser Europe magazine.