Technologies that capture carbon dioxide directly from the air would help us to manage climate change and make profitable by-products in the process. But the financial feasibility of such schemes is controversial, as David Appell reports

The problem of climate change essentially boils down to this: can we find a way of keeping the number of carbon dioxide (CO2) molecules in the atmosphere to four out of every 10,000 molecules of air – or will the figure rise to five or more? If only that extra molecule could be plucked from the air, the climate problem could be mostly solved without a drastic restructuring of the world’s energy infrastructure. It may sound madly ambitious but that is just what a few scientists and engineers are planning to do, and hoping to make some money from it to boot.

Removing CO2 from the air is not an especially new idea. In fact, it is relatively simple and done on spacecraft and submarines all the time. But achieving “negative emissions” economically, at large scales, is a much harder and more urgent problem. Unless the energy used for the removal is carbon free, or sufficiently small, the benefits will simply not cover the costs. And therein lies the challenge.

Existing efforts to remove CO2 are based at power stations – which give off 40% of global CO2 emissions – and involve capturing the gas as it leaves the plant. But these techniques do nothing to counteract the 60% of global emissions that come from cars, buildings, ships, planes and other “point sources”. The search is therefore on for new techniques that directly capture CO2 from the air. Facilities performing this “air capture” could be located anywhere, utilizing the atmosphere as a pipeline from billions of sources of CO2, however minute or mobile.

Despite doubts arising from theoretical studies of the cost of carbon capture, those getting their hands dirty think that CO2 could be removed directly from the air in massive quantities for perhaps as low as $100 per tonne. Once collected, the CO2 could then be pumped underground into geologic storage areas – a technique known as sequestration – where it would be trapped for potentially millions of years, with little leakage, doing no harm to planet or people. The gas could also be sold to oil companies, which routinely inject carbon dioxide into oil reservoirs to reduce the oil’s viscosity, enabling easier extraction. Other customers could include large-scale flower growers, who fill their greenhouses with CO2 to keep plants warm.

The technology to do all of these things already exists, but in bits and pieces; the challenge is to put the various components together on a large scale, and to do so cheaply. One interesting initiative is the Virgin Earth Challenge, which was launched in 2007. Sponsored by Richard Branson, it offers $25m to whoever can demonstrate a sustainable and scalable design to permanently remove a billion tonnes of carbon from the air every year for 10 years. Some 2600 groups applied to the challenge and last November the finalists were picked – six from the US and one each from Denmark, Sweden, the Netherlands, Switzerland and Canada – who now have five years in which to win the prize.

One finalist is Carbon Engineering – a firm based in Calgary, Canada, that is financially backed by Bill Gates, the Canadian government and others. “We’ve made a huge amount of technical progress,” says the company’s chief executive David Keith, who is also a prominent climate scientist at Harvard University, “and we’re understanding how we might make it work as a business.”

According to climate expert James Hansen, there is certainly a need for such enterprises. As he wrote in 2007, the global surface warming that has already been (or is bound to be) created – coupled with the unceasing increase in carbon emissions, and the currently inadequate mitigation efforts (see “The carbon problem” below) – implies that “a feasible strategy for planetary rescue almost surely requires a means of extracting greenhouse gases from the air”. If CO2 could be captured from ambient air more quickly than nature does it, the world might even be able to overshoot whatever warming threshold is deemed “dangerous” and later stabilize the climate gradually via net negative carbon emissions.

Chemical capture

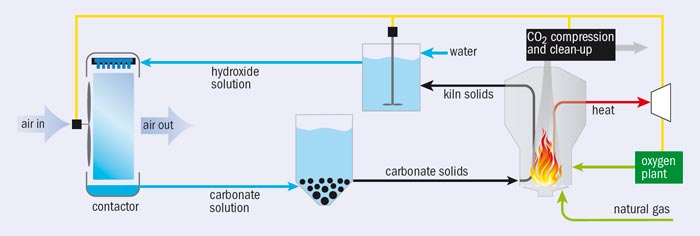

One of the most straightforward ways to remove CO2 from air is with a solid or liquid chemical compound that soaks up the gas. Known as “carbon dioxide scrubbing”, it is a tried and tested technique that has been used at power plants, and Carbon Engineering and other similar companies have made it their method of choice because the process is simple, proven and continuous. Ambient air is first drawn through a scrubber or “contactor” where an alkali solution (such as aqueous lye) absorbs CO2 molecules and converts them into a carbonate salt. After the salt is heated in a kiln, the CO2 is then released and captured, before the residue is reacted with water and other compounds to produce the same liquid alkali, which is then fed back into the contactor to be reused. The net yield is concentrated CO2 gas (figure 1).

Carbon Engineering has successfully built air-capture prototypes powered by natural gas, the CO2 from which is directly captured and combined with that extracted from air. Because atmospheric CO2 is well mixed, such plants could be sited where energy costs are lowest, environmental conditions such as temperature or humidity are most favourable, or where CO2 disposal is cheapest and most convenient. (In contrast, power plants are not necessarily located where CO2 sequestration is possible or most practical, often requiring that the gas be piped elsewhere.)

Scrubbing CO2 from the waste flues of power plants today costs $50–100 per tonne of CO2, a value that air-capture proponents dream of someday reaching. Once the CO2 is captured it is ready for sequestration or reuse, ideally at the same location. Pipelines and injection wells would have their own regulatory challenges, issues of public acceptance regarding impacts and leakage, and expense (see “Burying climate change for good”). The few sequestration projects that exist today, such as that at the Sleipner gas field in Norway, which has been running since 1996, all involve capturing CO2 from flue gases, but bury only about a million tonnes of CO2 per year.

Artificial leaves

Ambitious carbon-capture schemes are all very well and good, but there already exist amazing machines capable of removing CO2 from the air: plants and trees. Every year, land vegetation sucks up about 220 gigatonnes (220 × 109 tonnes) of CO2 in photosynthesis, although it is, of course, returned to the atmosphere when the plants and algae die and decompose. Vegetation is therefore not a net sink of CO2 – but there are clever ways to turn it into one.

Since carbon makes up about half the dry weight of a tree (depending on species), Ning Zeng, a climate scientist at the University of Maryland, suggested in 2008 how to temporarily solve part of mankind’s carbon problem by using forests as “carbon scrubbers”. This would involve actively managing them by collecting trees and woody debris, before anaerobically burying them deeper than five metres.

Zeng published another paper last year, which found that if wood was harvested from half the world’s forested land and then buried underground, 2.8 gigatonnes of carbon would be trapped per year. (If this carbon was instead allowed to decompose it would release 10.3 gigatonnes of CO2 into the atmosphere.)

Likewise, in a world stressed for agriculturally productive land, planting (or recovering) enough forest land looks out of the question, which is why some scientists are looking at making artificial leaves and artificial trees. These structures not only take CO2 out of the air as does conventional photosynthesis, but some also produce carbon-neutral liquid fuels in the process.

In photosynthesis, plants convert the energy of sunlight into stored energy in the form of carbohydrates, removing CO2 and producing oxygen and water in the process. Scientists are trying to do much the same thing, but with “leaves” made of silicon or polymers. Some implementations are sources of carbon-free energy, collecting sunlight that generates oxygen and hydrogen gas for fuel cells. But for Klaus Lackner, a physicist at Columbia University, the focus is to absorb CO2. His carousels of plastic filters are laced with a CO2-absorbing material; as they become saturated with CO2, they are rinsed with water in a vacuum chamber and the dissolved CO2 separates for collection.

Lackner’s leaves are about 1000 times more efficient at absorbing CO2 than real leaves, per unit surface area, and need not be exposed to sunlight, so they can be closely spaced. However, they do not come cheap: a single tree, which can remove one tonne of CO2 a day, currently costs about $20,000. Kilimanjaro Energy, Lackner’s company, plans to develop and commercialize this and other carbon-capture technologies, and is one of the Virgin Earth Challenge finalists.

Cost controversy

Accompanying these emerging air-capture technologies is the ultimate hope that they might be useful to help stop climate change, and perhaps even reverse its effects by returning the atmosphere and oceans to something like their pre-industrial state. A 2011 report by the American Physical Society (APS) entitled Direct Air Capture of CO2 with Chemicals, however, cast doubt on such ambitions. The APS report set out to explain the basic principles, technology and economics of air capture with chemicals to non-experts, and to encourage discussions among a broad audience of scientists and policy-makers.

One key figure in the report is that a typical sorbent would capture, per square metre over which air flows, only about 20 tonnes of CO2 per year. Since a 1000 MW coal-fired power plant emits about 6 megatonnes of CO2 annually, a 10 m high capture material would need to be 30 km long to adsorb the plant’s entire emissions. The report also estimated that a direct air-capture system, built today, would cost at least $600 per tonne of CO2. Direct air capture, it concluded, “is not currently an economically viable approach to mitigating climate change”.

Critics hit back, suggesting that these pessimistic predictions were premature at best, and even potentially misleading. Indeed, the report and its backlash from some respected scientists garnered a good deal of media attention, including a lengthy write-up in the New York Times. Mark Workman, a researcher at the Grantham Institute for Climate Change at Imperial College London, who recently co-authored an assessment of negative-emissions technologies, calls the report “controversial” and says “estimates of the cost of negative-emissions sequestration are often used to either negate or endorse the role of negative-emissions technologies in addressing climate change, and therefore often subject to political bias”. The high cost estimates are motivated, he says, by “a desire to keep the focus solely on preventing climate change via mitigation”.

The report does indeed state that it provides “no support for arguments in favour of procrastination in dealing with climate change that are based on the imminent availability of direct air capture as a compensating strategy”. But Workman feels “the mitigation narrative isn’t working” and sees negative-emissions technologies as an essential bridge. “We need to develop this line of research in order to buy time to introduce the low-carbon economy at rates at which energy-system technologies take to diffuse, which is up to 100 years, rather than being compressed into the next 30–40 years,” he says.

Carbon Engineering research scientist Geoffrey Holmes, on the other hand, thinks that air-capture plants in reality will be more efficient than the model used as the basis for the report’s predictions. “One crucial point,” says Holmes, “and one opportunity that the APS authors missed in their system, is that our heat and power generation are integrated on-site, so when we use energy to capture CO2 from the air, we also generate all the electricity demand for our own plant, and we capture the CO2 created by the gas combustion to produce that energy.” This avoids emitting new CO2 that would partially counteract the CO2 just captured.

Another way Carbon Engineering has lowered its costs is by designing its contactor structures around cooling tower technology – which is optimized to cheaply and efficiently ingest bulk quantities of air – rather than traditional gas scrubber technology. While the details are proprietary, their structure costs less than half of a similarly sized contactor considered in the APS report.

The company has now started work on a pilot plant near Alberta that aims to capture 500 tonnes of CO2 per year and test equipment and designs ready for a commercial-scale plant that is planned to capture 100,000 tonnes of CO2 annually. While Carbon Engineering’s carbon-capture rate is slightly higher than the APS report’s prediction, to achieve it they will need to use many stacked vents and contactors.

Carbon Engineering chief Keith sees the removal of CO2 as just one prong in the attack on climate change and, along with other entrepreneurs, is far more interested in the business opportunities. Keith sees the big prize as being direct fuel synthesis. Captured CO2 could be fed to algae to produce biofuels, or reacted with hydrogen molecules (obtained by splitting water using renewable energy) to produce high-energy-density carbon-neutral hydrocarbon fuels that could power cars, trains and planes that emit no net carbon pollution. Keith believes the price of such carbon-neutral liquid fuels might someday slash prices at the pump.

There are certainly many other ideas for how CO2 might be removed from air faster than natural processes. For example, iron fertilization of ocean regions would create algal blooms that, when they die, take the carbon with them to the ocean floor. Another options is “accelerated weathering”, which could fix a concentrated stream of CO2 as carbonate by reacting it with natural silicates, speeding up a process that in nature takes millennia. Reforested land, meanwhile, would remove about 50 kg of CO2 per square metre.

Race against nature

Should a climate emergency appear – perhaps a sharp acceleration in the melting of the Greenland or Antarctic ice sheets, or a steep rise in radiative forcings as rapidly thawing permafrost releases methane – the world may be willing to pay whatever it takes to remove CO2 from the air.

Our best guess is that the CO2 from the roughly 40% of emissions coming from power plants could be captured for about $50 per tonne. If air-capture technology drew down the remaining 60% from smaller sources for, say, $100 a tonne, the total cost would be more than $2 trillion to negate one year’s emissions at current rates of about 30 gigatonnes of CO2 per year. This is equivalent to a hefty 4% of the world’s total GDP.

While that figure is about twice as expensive as the (revised) estimate of the Stern Review – a report compiled for the British government in 2006 to assess the costs associated with mitigating climate change – air capture would have several advantages over currently envisioned mitigation schemes. Primarily, it would not require unilateral action across the entire planet or rebuilding an infrastructure the world has spent the last 150 years perfecting. Like carbon offsets, carbon could be captured by whomever can do it easiest and wherever they can do it cheapest. And it would eliminate the morality play that now accompanies the climate debate, where ends and means are often reversed as different factions use climate change as a cudgel in the fight for their individual causes.

As Keith wrote in Science in 2009, “Unless we can remove CO2 from the air faster than nature does, we will consign Earth to a warmer future for millennia, or commit ourselves to a sustained programme of climate engineering.”

And those are options nobody wants.

The carbon problem

Despite all warnings, emissions of greenhouse gases are increasing exponentially – a predicament the seriousness of which many still do not appreciate. The CO2 emitted by the average Briton over just 80 minutes – about 1.3 kg – will ultimately trap a Hiroshima bomb’s worth of heat: 63 terajoules. That heat will alter the Earth’s climate and oceans for millennia – the CO2 content of the Earth’s atmosphere will be about 10% higher 100,000 years from now than it would be without today’s emissions.

But solving the problem by replacing our energy system is daunting indeed. With colleagues, Ken Caldeira of the Carnegie Institution for Science has calculated that the world needs to install roughly one large (900 MW) carbon-emissions-free power plant every day for the next 50 years to stabilize overall global surface warming at 2 °C. And if, as seems likely, the target is relaxed to something like 4 °C, the required number is still about one power plant every two days.

To date, mankind has emitted about 1400 gigatonnes of CO2 from burning fossil fuels, and another 600 gigatonnes from land-use changes such as deforestation. But there are still enormous amounts of economically viable fossil fuels left to extract and burn, of which 70% is in the form of coal; if we used it all it would unleash a further 3200 gigatonnes of CO2. In fact, burning all the fossil fuels on the planet would create at least 37,000 gigatonnes of CO2, and for every 1000 gigatonnes emitted, the climate response is about 0.4 °C of surface warming, plus or minus a third. Humans could easily create an inverse ice age if we wanted to – a mean global surface warming of 6–7 °C, or more.