Joshua Pearce describes how physicists can help bring simple, affordable and life-changing devices to people and laboratories all over the world, using the concept of open-source appropriate technology

Several years ago, I was teaching introductory physics lab courses at a small university. As is common at many universities, much of the equipment there was outdated, and the experiments – one of which actually included watching ice melt – left a lot to be desired in terms of igniting my students’ enthusiasm for the wonders of physics.

At the same time, as part of my own research on solar energy, I had just begun taking a serious look at the concept of appropriate technology (AT). This term comes from the world of economic development, and it refers to technology that can be easily and economically constructed using materials and techniques that are readily available to local crafts-people. In academic studies and early work by the World Health Organization (WHO), AT has been shown to play a central role in the alleviation of poverty in the developing world. Yet research and development on these technologies generally receives only modest support from institutions in richer countries. One reason for this lack of support is that the operation of many AT devices depends on relatively well-understood science. In fact, it depends on the sort of science that is accessible to pretty much anybody – including my introductory physics students.

This was my eureka moment. My budget for the labs was small, but since one of the key tenets of AT is that people living on $1 per day should be able to afford to use it, cost was not a barrier. I therefore designed a class project in which students had to develop an appropriate technology, build it and finally design a physics lab experiment around it. They worked in teams, brought the equipment (largely scavenged) to class and then traded experiments with their peers. We did several “round robin” sessions so that everyone got to investigate several physical phenomena. Some students who were interested in mechanical properties built a bicycle-powered table saw. Another group put together a vertical-axis flexible-blade windmill. Many students explored basic thermodynamics and heat transfer by constructing a plethora of individual-scale or village-scale solar-powered devices, such as water pasteurizers, dehydrators, ovens and stills.

This project-based assignment motivated students to learn physics by offering them a chance to make concrete contributions to sustainable development. And it worked: the sense of exploration and excitement in the room was palpable, and the class’s average scores on an exam after the project were significantly higher than the average achieved in exams before the project.

A history of the AT movement

I was not the first person to stumble on the idea of mixing physics and AT. In 1980 Peter Logan – an applied physicist then based at the Papua New Guinea University of Technology – suggested that physics could play a major role in sustainable development by contributing to the interdisciplinary field of appropriate technology. Logan’s paper (Physics in Technology 11 187) followed a period of explosive growth in appropriate technology; in the 1960s and 1970s, groups such as the WHO made it part of their programme to eliminate poverty. Unfortunately, in the years that followed, the concept of AT went into decline as large development projects (such as dam building) generally became the internationally favoured solution to poverty. These monster projects had their own problems, since much of the funding ended up being “recycled” back to wealthy countries at the expense of poorer ones, but AT was viewed as too cumbersome and difficult to scale. How could you get water-pump designs that worked in Africa to remote villages in Peru where people were experiencing identical problems with their water supplies? If only there was some form of global, interconnected communication system for people to share good ideas!

In its early years, the AT effort was perhaps ahead of its time. Now, however, the Internet has made it relevant again. Reinvented as open-source appropriate technology (OSAT), the modern form of AT focuses on technologies that promote sustainable development and are designed in the same fashion as free and open-source software (FOSS). A typical FOSS program grants users the right to use, copy, study, change and improve its design, and it facilitates this by making its source code readily available (“open source”). The open-source paradigm normally also includes a viral component, such as requiring users to share improvements with the community under the same open/free terms that applied to the original program. These viral qualities help open-source technologies develop quickly, since they enable massive global teams to work together. Above all, the open-source movement treats its users as developers by encouraging contributions, recognizing good work through peer approval and helping superior code propagate through the software “ecosystem”.

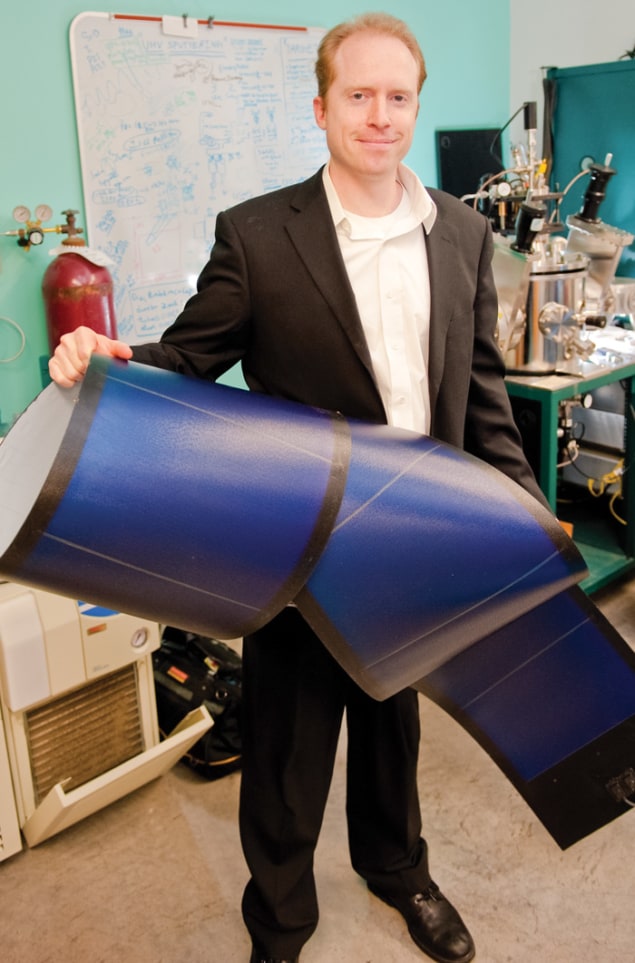

These same principles also apply to OSAT hardware. Such hardware can be simple and elegant, as with the treadle pump (see “A foot-powered water pump”) and a device that uses ultraviolet light from the Sun to purify water (see “Sunlight is the best disinfectant”). However, it can also encompass complex and state-of-the-art devices such as LEDs and photovoltaic cells on flexible substrates. In fact, even hi-tech devices such as mobile phones can sometimes be used in “appropriate” ways. For example, Bangladesh’s national “Village Phone” programme, which primarily targets women living in remote areas, works like an owner-operated payphone. To cover the initial costs of the phone, borrowers take out a $200 loan from the Grameen Bank, a Nobel Peace Prize-winning organization that specializes in this type of “microfinance”. They then subscribe to a related telecoms firm, Grameenphone, and are trained on how to operate the phone and how to develop a business by charging others – such as small farmers, who need to determine the best local city to take their produce to on a given day – to use it. With OSAT, the conflict is not between hi-tech and low-tech, but between appropriate tech and inappropriate tech. The most important feature of any OSAT device is that it must take into account any limitations imposed by the cultural, economic, educational and environmental resources of the local community.

Fully formed

One particularly interesting recent area of OSAT development is “distributed additive manufacturing”, which uses 3D printing to make everything from solar-distillation devices to hand-cranked generators. Broadly speaking, 3D printers work by taking in a filament of the working material (a popular one is a plastic called ABS, which is used in making LEGO bricks), heating it and then extruding it through a nozzle to produce a single 2D layer. By raising the printer’s vertical axis and repeating the process many times, it is possible to construct a 3D object layer by layer (see September 2013 pp25–29).

Although some commercial 3D printers cost thousands of pounds, there is an open-source 3D printer known as a RepRap – the name is short for “self-replicating rapid prototyper” – that can be built for less than £400 and is capable of printing around 50% of its own components. RepRaps use computer-aided designs that can be shared over the Internet as easily as photographs. Hundreds of RepRap-friendly designs for OSAT devices exist already, including “recyclebots” that turn waste plastic into 3D printer filament. It is also worth noting that components of many scientific instruments can be made using RepRaps – a fact that could reshape the landscape of science education and research in developed countries as well as developing ones (see “Open-source 3D-printed scientific equipment”).

There is plenty of research left to do in this area, including improving local availability of feedstock for polymers and other materials (including ceramics and metal); increasing the maximum size of printed parts; improving the material properties of the printed objects; and using renewable-energy systems to power the production. My collaborators and I have already started working on solar-powered 3D printers that fit in a suitcase. However, more work is still needed to extend existing 3D printing technology before a complete, village-level OSAT fabrication process will become a reality.

Getting involved

Physicists have a good track record of opening up science for the common good. We have been sharing our open-access e-prints on arXiv for more than 20 years, long before “open access” became a buzz-word. Given this background, I think it is time for physicists to take a serious look at OSAT.

If you are already doing research that could directly contribute to sustainable development, I suggest you start sharing your work on Appropedia. This advertising-free website works like Wikipedia – anyone is allowed to create and modify content directly from their Web browser – and it has become the primary site for collaborative solutions in sustainability, poverty reduction and international development. On it, you will find project examples, descriptions of best practice, “how tos”, ideas, designs, observations, experimental data, deployment logs and much more. Most of the projects on there have been created by development workers and students, and many of them would benefit from the analytical minds of physicists. In addition, Appropedia would welcome summaries of your latest results on technical topics related to the site’s mission. And of course, if you need field partners to help test some of your ideas, there are some perfect collaboration opportunities just waiting to happen.

But even if your research is not directly related to appropriate technology, you can still contribute to OSAT by making your own designs for customized lab equipment into open-source hardware. These contributions can include the bill of materials and instructions for operating equipment you have already made; or you can design new tools, which can be 3D printed. A good program for doing this is OpenSCAD – a free, open-source application that uses a script containing details of an object’s geometric parameters as its input. If you can already program a computer, you will be able to easily learn OpenSCAD. OpenSCAD is extremely powerful as it enables designs to be fully parametric, meaning that changes can be made simply by adjusting the value of user-defined variables. Another useful customizing tool can be found in the Thingiverse, one of many digital repositories of free printable designs. This repository includes an application that converts OpenSCAD scripts into easily manipulated designs that anyone can use.

By sharing equipment designs with the open-source community, you will help other groups lower their laboratory costs and make your equipment accessible to researchers in the developing world. Moreover, you will also benefit directly when members of the international open-source community hack your equipment to improve it and then share the new, enhanced design with everyone. With OSAT, we all win.

Open-source 3D-printed scientific equipment

A number of designs for scientific equipment are available online. For example, some of my work on solar water purification requires heat exchangers, which needed very expensive prototyping with laser welding. We were able to build a digitally controlled laser welding system, using printed parts and open-source plans, for less than the price of a single heat-exchanger prototype. We also used a script in OpenSCAD to make a chemical oxygen demand analyser (see “Printable lab equipment”). This analyser runs on a simple version of an open-source Arduino Uno microcontroller and all the black components were synthesized using a RepRap 3D printer. We have shown that it is as accurate as commercial models but costs two orders of magnitude less.

If your research takes place on the nanoscale, you might be interested to hear that the University of Münster in Germany has developed an open-source scanning tunnelling microscope for a fraction of the cost of commercial systems. If your work requires optics, you might consider using a RepRap to print components from the open-source optics library. This library contains free designs to build a research-grade Michelson interferometer or a hand-held spectrometer, along with many other tools. And physics teachers, take note: a basic optics lab set-up for an entire class costs only about £300 to print, compared with a retail cost of about £9000. I have documented dozens of other examples in my book The Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs (2014 Elsevier).