Andrew Ouderkirk and colleagues from 3M in St Paul, Minnesota, have made a multi-layer polymer mirror that can reflect visible light from all angles (Science 287 2451). The new cheap, flexible, organic mirror can be used to transmit visible light over long distances, and illuminate small computer displays. Two years ago Yoel Fink and a team based at the Massachusetts Institute of Technology made a similar dielectric mirror containing organic and inorganic compounds that reflected infrared - rather than visible - light (Science 282 1679).

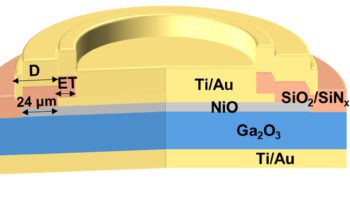

Dielectric mirrors are made of multiple layers of transparent materials, each of which reflects a small fraction of the light that hits it. At a specific layer thickness, the reflected light waves merge and amplify, intensifying the reflection. In earlier dielectric mirrors, the efficiency of the mirror fell as the angle of reflected light increased – until at a critical angle no light at all was reflected. This effect is known as Brewster’s law.

However, the new polymer mirrors have alternating layers of positive and negative “birefringent” materials such as polymethylmethacrylate and polyester. Light passing through the birefringent polymer splits into two rays that travel through the material at different speeds. By controlling the interactions of the reflected light beams, the researchers were able to minimise the effect of Brewster’s law and induce light to reflect off the polymer mirror, no matter what its initial angle of approach.