Physicists have developed a new high-temperature superconducting material that can support current densities greatly exceeding anything previously reported. German Hammerl at the University of Augsburg in Germany and colleagues at the University of Twente in The Netherlands have produced a multilayer structure that overcomes the long-standing problem of current loss in high-temperature superconductors (G Hammerl et al 2000 Nature 407 162).

The discovery of high-temperature superconductivity in 1986 raised hopes that loss-free superconducting power cables would be able to operate at liquid nitrogen temperatures. Previously, superconductors had to be cooled with liquid helium, which is much more expensive. But researchers soon found that the new polycrystalline superconductors could support only extremely low current densities at this temperature. This is a result of the large degree of misalignment between the individual crystals in the superconductors. Further studies suggested that oxygen depletion at these large-angle boundaries results in a lack of charge carriers, which leads to the drop in current. This prompted Hammerl and co-workers to investigate the possibility of repopulating or “doping” the boundary regions with charge carriers to stem the loss of current. “We observed the first enhancements of the critical current just a few days after we had the idea”, Jochen Mannhart, one of Hammerl’s colleagues, told PhysicsWeb.

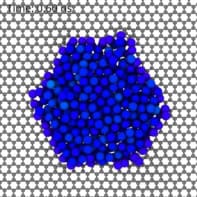

The team interleaved layers of superconducting yttrium barium copper oxide (YBCO) with layers of calcium-doped YBCO, each 25 nm thick. Calcium ions are similar in size to yttrium ions but have a smaller positive charge. When these calcium ions take the place of yttrium ions in YBaCuO, they act as ‘positive holes’, charge carriers opposite in polarity to electrons. The group found that the holes diffused preferentially into grain boundaries in the adjacent undoped layers and increased the inter-grain current flow by between three and six times. “It would be particularly exciting to measure the calcium concentration around the grain boundaries and determine its electronic structure”, explained Mannhart, “and we have plans underway to do that”.

Mannhart and colleagues believe that their techniques could be transferred to the manufacture of high-temperature superconductors, but emphasise that although the results are highly encouraging, an industrial process has yet to be devised for large-scale fabrication.