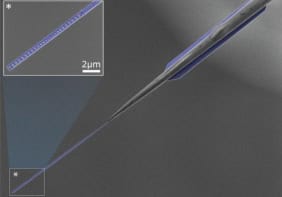

Scientists in China have developed a new way to make multiwalled carbon nanotubes -- by heating grass in the presence of oxygen. The nanotubes, which were about 1 micron long and 30 to 50 nanometres in diameter, could prove useful for catalyst applications (Nanotechnology 16 1192).

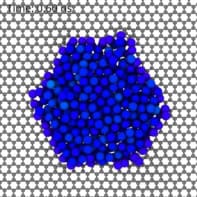

Enbo Wang of Northeast Normal University in Changchun and colleagues took grass from a field and heated it at 250 °C for one hour. The scientists then heated the resulting material at a higher temperature of 600 °C for around 20 minutes in a sealed container containing about 15 millilitres of oxygen. Next, they cooled the mixture and repeated the heat treatment. This cycle was carried out about 50 times and the estimated average yield for the process was roughly 15%.

Recently scientists have shown that water can simplify the synthesis and purification of nanostructured carbon based on the complex chemistry that is found in the carbon-hydrogen-oxygen system. “That inspired us to look for a new strategy for making carbon nanotubes directly from carbohydrates, based on the conversion from carbohydrate to pure carbon and water,” says Wang.

Many plants, including grass, contain tube-shaped bundles that are mostly made of cellulose and lignin and are used to transport fluids throughout the organism. The Northeast Normal team believes that pre-treating the grass removes its protein and grease components, while the treatment at high temperatures dehydrates the cellulose and converts it into nanostructured carbon.

The tubular structure of the carbon sources appears to be crucial because using the same heat treatment on non-tubular carbohydrates, such as glucose and saccharose, produced a much lower yield of nanotubes. However, wood and hemp, which do have tube-like structures, were also found to be good sources of nanotubes.