A new and simple way to determine the mechanical properties of very thin films has been unveiled by an international team of researchers. The technique involves studying the wrinkles that are created in the film when a drop of water is placed on it. By counting the number of wrinkles and measuring their lengths, the thickness and elasticity of the film can be determined to about the same accuracy as much more sophisticated methods such as X-ray reflectivity (Science 317 650).

The new technique has been developed by Thomas Russell and colleagues at the University of Massachusetts along with collaborators in the Netherlands and Chile. They studied a number of polystyrene films of known thicknesses ranging from 31 to 233 nm. Each film was floated in a dish of water and a tiny drop of water (less than 1 mm radius) was placed at its centre.

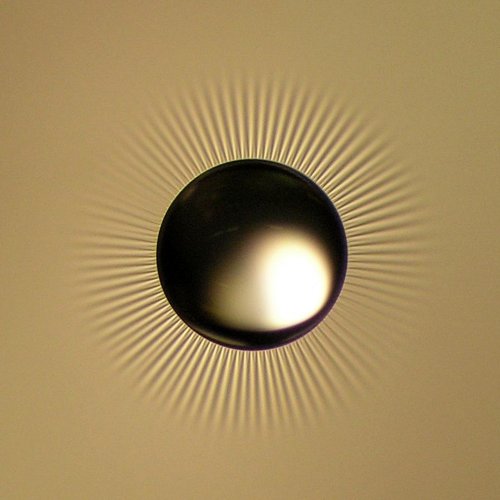

The capillary force between the drop and the film created a series of wrinkles that radiated out from the centre of the drop (see Radiating wrinkles). The researchers discovered that the number of wrinkles was a well-defined mathematical function of the radius of the water drop and the thickness of the film. Large drops created more wrinkles than small drops, and thin films had more wrinkles than thick films. Once this relationship was established, the thickness of an individual film could be determined by simply counting the wrinkles and measuring the diameter of the water drop.

The team then added varying amounts of a chemical compound to the polystyrene, which changed its elasticity. By measuring the average wrinkle-length in films of different elasticity and thickness, the researchers discovered that wrinkle-length is a function of the elasticity and the thickness of the film.

As a result, the elasticity and the thickness of a film could be determined by simply measuring the length of the wrinkles and counting their number. Currently, elasticity and the thickness must be measured separately using expensive and time-consuming tests such as stress-induced buckling and X-ray reflectivity. “Anyone can do the [wrinkle] measurement with a cheap optical microscope”, said Russell. He also told physicsworld.com that the technique could be used on any material that can be made into a thin film.