Physicists in the US claim to have created the first thin optical film with a refractive index close to that of air. The film consists of an array of obliquely-deposited nanorods, which can collectively have a refractive index as low as 1.05. The physicists also claim several graded layers of the films can produce an optical coating that "virtually eliminates" reflection at all wavelengths (Nature Photonics to be published).

The refractive index is perhaps the most fundamental quality in optics because it describes how the speed of light changes as it enters a substance. As a result light passing through one substance is more likely to reflect off another if the difference between their refractive indices is greater – a relationship quantified by Augustin Jean Fresnel almost 200 years ago.

For this reason, if a material encompassed by air is to minimize the amount of light it reflects, its surface must have a refractive index close to that of air, which is almost one. But solids in general do not have indices between 1 and 1.4, and those that do exist are synthetic porous materials that cannot be made thin enough for viable optical coatings.

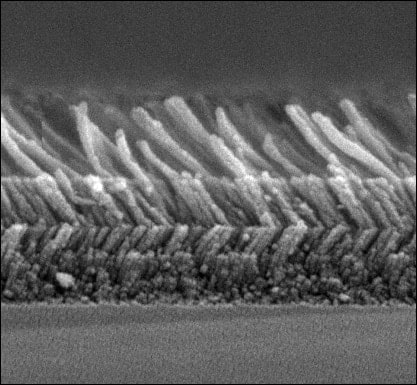

Fred Schubert and his team from the Rensselaer Polytechnic Institute in New York, however, have now invented a new class of thin-film materials with refractive indices as low as 1.05. To make the materials, they deposit silica nanorods at an oblique angle onto an aluminium nitride surface. These nanorods are separate enough to allow air to reside between them, so the effective refractive index is that of the nanorods and air combined. Therefore, by increasing the proportion of air, the refractive index can be lowered towards one.

More importantly, however, the actual value of the refractive index can be precisely tuned by altering the angle of deposition. This enabled the physicists to produce almost perfect anti-reflection coatings by having several layers of graded-index material stacked one on top of another. The grade with a refractive index close to that of the underlying material is deposited first, with successive grades decreasing in refractive index until the final layer – the one in contact with air – has the low index.

Schubert told Physics Web that his team are now planning other types of optical material using the same fabrication process such as distributed Bragg reflectors, which would have alternating high/low graded-index layers.