Having an operation in hospital is no fun and you certainly don’t want to catch a bug while under the knife. That is why one of the most critical tasks faced by medical staff is to ensure that equipment used in surgery is always completely free of contaminants. Although the cleaning process, which involves using ultrasonic waves, has been honed over many years, the means for testing its effectiveness has remained fairly primitive.

Ultrasonic cleaning involves immersing surgical instruments in a disinfecting liquid and firing high frequency acoustic waves through the mix, which causes tiny bubbles in the liquid to implode – a phenomenon known as cavitation. The force created when these bubbles collapse is enough to remove contaminants on the surface of the surrounding material. Given that each implosion leads to new bubbles, and that there are over 200, 000 sites in one teaspoon of water where bubbles can emerge, cavitation is believed to provide a very effective mechanism for cleansing.

However, there are no established means of quantifying cavitation, and so the alternative is to measure the usefulness of bubble collapse indirectly. The favoured means at present is to simply dunk a sheet of aluminium foil into the liquid and observe the number of “dents” caused by bubble implosions. The major limitations with this approach are that is it only qualitative, and that it lacks repeatability: it cannot reliably resolve the “hot and cold” regions where cavitation (and hence cleaning activity) varies within the liquid.

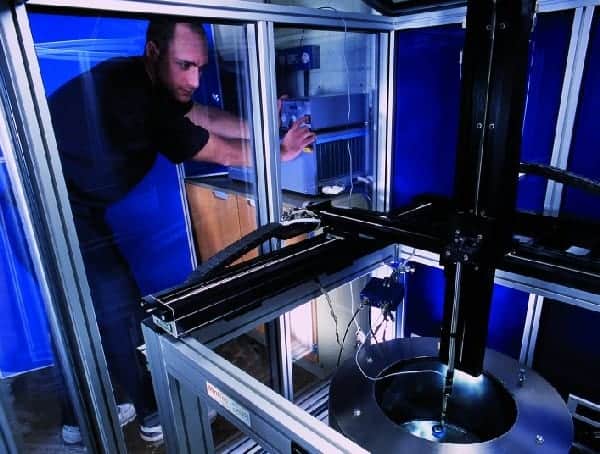

To overcome these limitations, and to provide a quantitative measure, researchers at the National Physical Laboratory (NPL) in the UK have developed a sensor that can monitor the amount of cavitation produced in cleaning vessels. The sensors, which are hollow cylinders fabricated from a thin layer of piezoelectric material sandwiched between special absorbers, are designed to sit in the liquid and record the spatially-variant, high-frequency “noise” of bubble implosions.

“Occasionally, there are cases where medical facilities can become contaminated but it can be very difficult to trace the source. This device, and the capability it provides is a step in the right direction to improve the application of ultrasonic cleaning,” says Mark Hodnett, one of the researchers at NPL.

The team now plan to conduct further trials and will launch a new reference facility for acoustic cavitation at NPL within the next few months. “We’ve already sold half a dozen devices to ultrasonic equipment manufacturers that supply hospitals, and we’re now looking to get the product fully commercialized,” adds Hodnett.