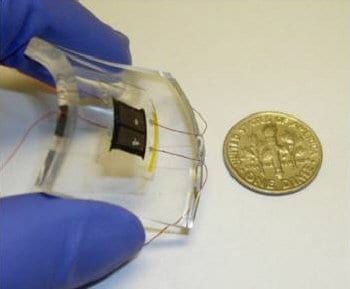

A new type of solar-cell module based on arrays of tiny pillars has been made by researchers in the US. According to its inventors, the module is flexible, efficient and can be made using industrial processing techniques — which means that it could offer a low-cost route to efficient and robust solar panels.

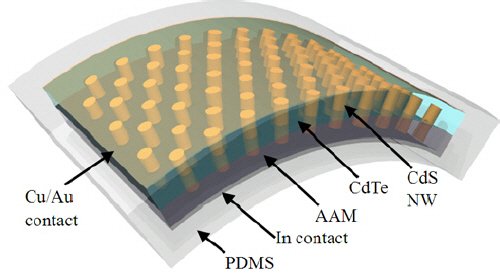

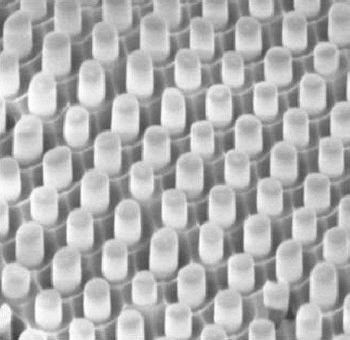

Ali Javey and colleagues at the University of California at Berkeley grew regular arrays of cadmium sulphide (CdS) pillars on anodized aluminium-foil membranes. The pillars are identical cylinders, which are each a single crystal about 200 nm in diameter and about 500 nm tall.

To make the pillars, the team deposited a thin layer of gold seeds in the highly regular pores that form in the aluminium foil after anodization. These seeds encourage the growth of the nanopillars when exposed to a vapour-liquid-solid (VLS) process — a technique that produces ordered structures with an orientation that can be controlled.

CdS is a semiconductor and the nanopillars function as photoelectrodes, which convert light into electrical current. Previous studies have shown that such structures have a higher efficiency than flat surfaces because more photons are absorbed at greater depths in the photoelectrode.

The team then fabricated solar cells from the nanopillar arrays and achieved a conversion efficiency of about 6%. This is higher than many other thin and flexible devices, including those based on nanostructured materials. Another advantage compared with bulk solar modules is the small amount of active semiconductor used in the device, which makes them more cost-effective, says Javey.

The technique also shows commercial promise because it could be compatible with “roll-to-roll processing”, which is used to make electronic devices.

“The nanopillars we produced could be used to develop a robust technology for low-cost and lightweight photovoltaics with respectable efficiencies,” he says. “Our work could have important implications for the large-scale integration of solar modules for a wide range of applications. There are still a lot of challenges ahead of us, but the work shows the potential of our technique.”

The team, which includes researchers from the Lawrence Berkeley National Lab, now plans to further enhance light-conversion efficiencies in the devices. The first thing that they will do is optimize and/or replace the top contact material, which is currently causing a 50% loss in the optical transmission. “We will also explore other materials systems by using our device structure and fabrication approach and try to make the technology more viable for large-scale integration,” added Javey.

In particular, the researchers will try to replace the cadmium-based materials used in their devices, because the metal is highly toxic.

The work was reported in Nature Materials.