Coating an object with just one or two layers of carbon atoms gives it an extremely slippery yet tough surface, according to physicists in Germany and North America.

What’s more, the friction on a single layer of carbon atoms — known as graphene — is greater than on a double layer, which the researchers say is due to differences in how vibrating carbon atoms interact with surrounding electrons.

The results suggest that such coatings could reduce frictional wear and tear in tiny machines.

The new findings were made by a team led by Roland Bennewitz, who splits his time between McGill University in Montreal and the Leibniz Institute for New Materials in Saarbruecken, Germany. Researchers at McGill, the Lawrence Berkeley National Laboratory, University of Erlangen–Nuremberg and Max Planck Insititute in Berlin were also involved (Phys. Rev. Lett. 102 086102).

Graphene terraces

The team began by carefully heating a single crystal of silicon carbide (SiC), which causes carbon atoms to migrate to the surface of the material. This leads to flat “terraces” on the surface — with each terrace comprising exactly one, two or zero atomic layers of carbon.

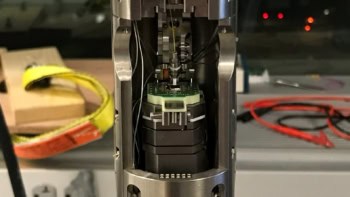

The researchers then put the silicon carbide in an ultrahigh-vacuum chamber before studying its surface properties using an atomic–force microscope (AFM). The team measured the friction on the surface simply by dragging the nanometre-sized tip of the AFM along the surface. Friction was measured on bare silicon carbide as well as in the presence of single and bi–layers of graphene.

Bennewitz’s team discovered that both single and bi–layers of graphene are much more slippery than bare silicon carbide. For example, when the AFM tip was pushed down onto the surface with a normal force of 100 nN, the frictional force on single and bi–layer graphene was found to be about 0.6 and 0.2 nN respectively. The friction force on bare silicon carbide, in contrast, was 8 nN.

Surprisingly slippery

Bennewitz told physicsworld.com that the team was “surprised” to find that a bi–layer of graphene is significantly more slippery than a single layer over a wide range of normal forces. They believe this is related to how quantized vibrations of the carbon atoms (called phonons) interacted with the electrons in the graphene — a process that is thought to dissipate some of the heat generated by the sliding tip.

To confirm this the team used a standard technique called angle-resolved photo-emission spectroscopy (ARPES), which revealed that electron-phonon coupling is much stronger in the single layer of graphene than in the bi–layer. Bennewitz likens the effect of the coupling to dragging the tip through sand — with the greater the coupling, the thicker the sand.

The researchers also studied friction in thicker multiple–layer coatings, and found these slightly less slippery than a bi–layer. This could be because the tip is able to dig into a multilayer and become stuck — something that was not seen with the bi-layers.

Hard-wearing as well

The team ended their experiment by trying to damage the graphene coatings using the diamond–coated AFM tip. They were unsuccessful, suggesting that the graphene coatings are hard-wearing as well as slippery.

The team’s results could be good news for researchers that are trying to build micro and nanometre-sized machines using silicon carbide instead of silicon — which is the conventional material for such devices.

These include Roya Maboudian at the University of California Berkeley, who described the discovery as “technologically exciting” and suggested that suggests potential opportunities for improving the reliability of nano and micro machines.