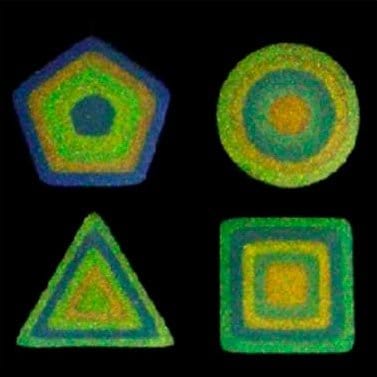

By mimicking the ‘structural colours’ found in butterfly wings and peacock feathers, researchers in South Korea and the US have developed a high-resolution patterning technique that produces multiple colours within seconds. If the technique is scaled up for commercial use, it could be used to prevent forgery and lead to the design of advanced materials, say the scientists.

“We have developed a simple, scalable way of producing structural colour,” explained Sunghoon Kwon, Seoul National University (SNU), who heads up the research. “We have overcome limitations in previous approaches to demonstrate rapid production of high-resolution patterns of multiple structural colours.”

Structural colours, such as those on butterfly wings and peacock feathers, differ from traditional pigments or dyes in that the colour results from the interaction of light with periodic structures on the surface of the material.

Cannot be mimicked or bleached

Among the advantages of structural colour are that it cannot be mimicked by chemical pigments or dyes and it is immune to photobleaching. What is more, multiple colours can be displayed using a single material simply by varying the dimension of the periodic nanostructures.

Such properties make structural colour printing attractive for a range of applications, including forgery protection and the design of new materials. To date, however, attempts to manufacture artificial structural colour have proved time-consuming. This is because they involve either the precise assembly of colloids of different sizes or the stacking and lithographic patterning of periodic dielectric materials.

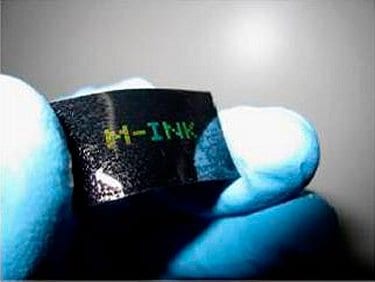

Now, Kwon and colleagues at Seoul National University, working in collaboration with chemists at the University of California at Riverside, have found a way to produce a single ink of any desired colour within a few seconds. The material, dubbed “M-Ink”, changes colour when a magnetic field is applied. What is more, the colour can be rapidly locked into the material by shining patterned ultraviolet light onto its surface.

Aligning along magnetic field lines

“Under an external magnetic field, the CNCs are assembled to form chain-like periodic structures” Yadong Yin, UC Riverside

“M-Ink is a three-phase material system consisting of superparamagnetic colloidal nanocrystal clusters (CNCs), a solvation liquid and a photocurable resin,” explained UC Riverside’s Yadong Yin, an expert in nanomaterials chemistry. “Under an external magnetic field, the CNCs are assembled to form chain-like periodic structures, which align themselves along the magnetic field lines.”

In a similar way as periodic structures in conventional photonic crystal diffract light at specific wavelengths, so too do the particles that make up the CNCs. A shorter interparticle distance corresponds to a shorter diffracted wavelength. Because the this distance is determined by the applied magnetic field, the colour of the material can be altered simply by varying the magnetic field strength.

Frozen in the polymer network

Once the desired colour is obtained from M-Ink, it can be fixed by solidifying the photocurable resin through ultraviolet exposure. The chain-like CNCs are then effectively frozen in the polymer network.

“We can freeze the self-assembled photonic nanostructure fast enough to prevent distortion” Sunghoon Kwon, Seoul National University

“As our photocuring is instantaneous, we can freeze the self-assembled photonic nanostructure fast enough to prevent distortion,” commented Kwon. “This means that we retain the structural colour.”

The group hopes to commercialize the material in conjunction with companies in the electronics or material design industries.

The work is described in Nature Photonics.