Physicists in the UK have made a new kind of flexible material that could enclose objects to render them and it invisible. Although unlikely to be of much use when it comes to shielding people and other large objects, it could, say the researchers, nevertheless hide small items and make contact lenses more powerful.

Over the last few years physicists have shown how to hide objects by placing them inside so-called invisibility cloaks. These cloaks are made from metamaterials – artificial, engineered materials that have unusual electromagnetic properties. The first such cloak was made from a cylinder consisting of copper rings placed in concentric circles, and enabled an object placed at its centre to be shielded against microwaves, the radiation flowing around the cloak and continuing along its original trajectory as if the cloak were not there. Researchers have since extended this concept to shorter wavelengths by making ever tinier features within the metamaterials, since the features have to be smaller than the wavelength of light used.

All cloaks to date, however, have used metamaterials rooted in hard substrates typically made from glass or silicon. Andrea Di Falco and colleagues at the University of St Andrews in Scotland have instead created a flexible metameterial, operating at visible wavelengths, which, they say, should give metamaterials a much broader range of practical applications. The inspiration was the kind of flexible electronic circuitry used in laptops to connect the screen to the keyboard, but in this case applied to optical structures.

Introducing Meta-flex

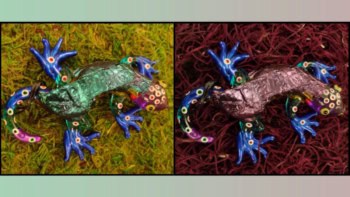

The researchers made their material, which they have dubbed “Meta-flex”, by placing a commercially available polymer known as SU8 onto a silicon substrate. They then deposited a 40 nm-thick gold layer onto the polymer and used electron-beam lithography to carve the desired metamaterial features into the gold, before immersing the structure in a suitable solvent to remove the substrate.

The researchers say they have been able to make pieces of Meta-flex as thin as 4 μm and having an area of 40 mm2. They tested the electromagnetic response of two different metamaterial configurations, known as nanoantennas and “fishnet” lattice, by exposing the material to a source of white light and then analysing the transmitted light using a spectrometer. They found that the absorption peaks matched those obtained with the equivalent rigid metamaterials, proving, they say, that Meta-flex can indeed function as an invisibility cloak.

Using this new material to carry out useful functions will require mounting multiple layers on top of one another. But doing so, cautions Di Falco’s colleague Thomas Krauss, will not lead to invisibility cloaks of the kind that could be used by real-life Harry Potters. Cloaks made from Meta-flex, he says, can be larger than the nanometre-scale features engraved into the the material but the size of these cloaks is limited by the need for the cloak to have a certain thickness. With a given fraction of the incident light absorbed by each layer, a thick cloak would absorb practically all of the light that fell on it. “We should be able to cloak objects on the sub-micron level,” he says. “And as we improve the material we should be able to increase this scale, but I find it hard to think that we will ever be able to cloak large objects”.

Better contact lenses

As an example of the kind of object that could be rendered invisible, Krauss suggests electrical cables integrated into clothing. However, he believes that Meta-flex will find more useful applications. For instance, he says, the material could be used to increase the correcting power of contact lenses, making lenses available to people who previously have had to make do with thick glasses. He points out that the ability to bend light is dictated by the variation in refractive index of the media that the light traverses, so making a metamaterial with a refractive index of close to zero creates a ratio of indices approaching infinity and therefore results in an extremely high corrective power. He says that although this principle has been demonstrated previously, it is the manufacture of a flexible substrate that renders it useful for the manufacture of contact lenses.

John Pendry of Imperial College in London, who has pioneered the use of metamaterials, describes the development of the new material as an “interesting and useful advance in metamaterial technology” but “very, very far from achieving a flexible cloak”. He points out that as the instantaneous shape of a cloak changes, so too do the electrical permittivity and magnetic permeability needed for invisibility. So a flexible cloak, he says, would require that the metamaterial be not only flexible but also one whose electrical and magnetic parameters can be continuously reconfigured.

Krauss acknowledges this point but maintains that as long as the shape of the cloak doesn’t change too much the metamaterial parameters can remain fixed. “For a Harry Potter cloak you would need to do what Pendry is saying, but for the kind of specific applications that we’re suggesting you could design a metamaterial of a certain curvature and leave it at that,” he says.

Meta-flex is described in New Journal of Physics 12 113006.