Researchers in US are the first to produce electrically conducting yarns from webs of carbon nanotubes and various powders and nanofibres. The yarns, made by a technique called biscrolling, are very strong and can be woven, sewn, knitted and braided into a variety of structures. They could find applications in energy storage and harvesting, structural composites, photocatalysis and intelligent textiles.

Current methods to transform powders with useful properties into yarns involve using polymer binders to fix the powders in place. A major problem with this technique, however, is that not much powder can be incorporated into the yarn and the resulting composites are not very strong. What is more, the desirable properties of the powder usually degrade during processing.

Now, Ray Baughman and colleagues at the Nanotech Institute at University of Texas in Dallas have developed a new approach that exploits carbon nanotube (CNT) sheets, or webs, instead of polymers to transform nano- or micron-sized powders into electrically conducting, sturdy yarns.

Drawing and twisting

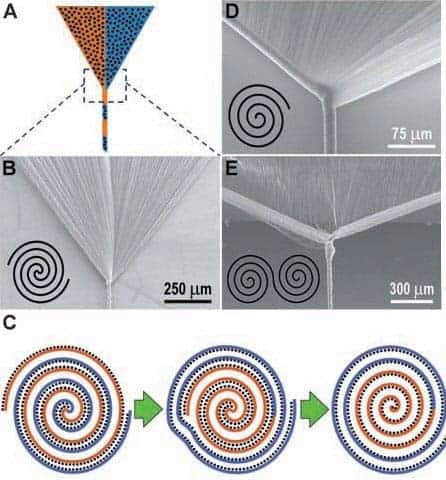

The researchers began by overlaying the “host” CNT sheets with “guest” powders using an electrostatic powder-coating gun and then twist-spinning the guest-host stack to form a biscrolled yarn. The technique is in fact adapted from traditional textile-spinning methods that have been around for millennia and involves drawing 10 nm diameter multiwalled carbon nanotubes from a “forest” of similar length tubes deposited on a substrate while applying a twist at the same time.

Depending on the final application desired, the twisting produces different-shaped structures – known as Archimedean, dual-Archimedean or Fermat scrolls. These structures are similar to the spirals commonly found in nature – for example, those seen in nautilus shells and the now-extinct ammonites.

The difference between the structures is as follows: Archimedean is where a sheet edge is buried deep in a scroll; dual-Archimedean means that the sheet edges are buried in different interconnected scrolls; in Fermat biscrolling, twisting starts from the centre of a symmetric spinning wedge, the edges of which then wrap in opposite directions around the scroll score.

CNT sheets are ideal for making such yarns; its sheets are nearly as light as air (they have a density of around just 1.5 mg/cm3) but are stronger than steel, with a specific strength that can reach 560 MPa cm3/g when densified. This is much higher than the values for Mylar and Kapton films used for ultralight air vehicles that have a strength of about 125 MPa cm3/g. The yarns can also happily be washed in an ordinary washing machine without suffering any measurable damage.

Making superconducting wires

The biscrolled yarns can be made from a variety of powders that can be chosen according to the final application. For example, Baughman and colleagues made superconducting yarn by biscrolling a mixture of magnesium and boron powders (up to 99 wt%) as the guest on CNT sheets, and then thermally annealing the biscrolled yarn. The technique has the added bonus in that it avoids the 30 or more drawing steps needed in conventional powder-in-tube methods to produce millimetre-sized, iron-clad, superconducting wires from a magnesium/boron/CNT precursor.

The team also made biscrolled yarns containing up to 98 wt% graphene oxide nanoribbons that were then converted to graphene nanoribbon yarn by reducing the graphene oxide. These yarns could be used to make weavable anodes for flexible lithium-ion batteries, says Baughman. The researchers showed that they could make electrodes for lithium-ion batteries using LiFePO4 (an environmentally friendly, inexpensive, high-performance lithium-ion battery cathode) as the guest powder.

My colleagues say that I’ll try to biscroll anything, as long as it has interesting properties for applications Ray Baughman, University of Texas at Dallas

The batteries perform well, with a high gravimetric electrical conductivity of 8 S cm2/g, are flexible and mechanically robust. These properties mean that they could be used in applications like energy storage and energy-generating clothing – so-called intelligent textiles. The high gravimetric electrical conductivity also makes for lighter batteries because biscrolled yarn cathodes no longer require the conventional aluminium current collector and conducting particle binders that can bump up electrode weight by over 30%.

And if that wasn’t enough, Baughman and co-workers also fabricated highly catalytic fuel cell cathodes by biscrolling nitrogen-doped carbon nanotube guests. These devices are promising for future applications because they do not contain any of the expensive platinum found in conventional fuel cells.

The biscrolling technique, reported in Science, is a generic one, Baughman says, and can easily be extended to electrically insulating hosts such as SiO2 and Si3N4 nanotubes, among other materials. “My colleagues say that I’ll try to biscroll anything, as long as it has interesting properties for applications!”

The work is described in Science 331 51.