Every seasoned flyer knows better than to carry a large bottle of shampoo, perfume or even champagne in their hand luggage. But all that might change, thanks to researchers in Europe who have developed a scanner to be used at airports to screen liquids in opaque or translucent bottles. The scanner is currently on trial at several European airports and might allow the ban on liquids of more than 100 ml in hand luggage to be lifted as early as 2013.

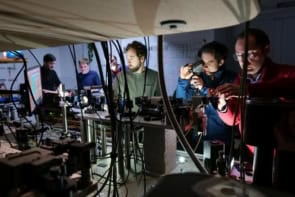

The scanner uses a technology known as spatially offset Raman spectroscopy (SORS). This is a variation on conventional Raman technology that allows a chemical analysis deep within a sample and that can be used to scan everything from bone beneath skin and drugs in plastic packs to liquids in opaque bottles. SORS was invented and developed by Pavel Matousek and collaborators at the Rutherford Appleton Laboratory in the UK in 2004. The new scanner is known as the INSIGHT100 and was by developed by Cobalt Light Systems – a company founded by Matousek in 2006 to develop technologies that utilize SORS.

Random photons

Conventional Raman spectroscopy relies on the inelastic backscattering of photons as light interacts with matter. Normally, the scattered photons are detected from the same spot on the sample that has been illuminated. The problem there, explains Matousek, is that Raman signals from surface layers tend to dominate those signals from within the sample. “If you apply Raman spectroscopy to, say, biological tissue or plastic pill bottles, you only get a surface signal…you can’t see deeper,” he explains. To get round this issue, the researchers use SORS to collect photons from a spot a few millimetres away from the illuminated area – a “spatially offset” spot. This works because photons migrate from the illuminated spot and travel through the body of the sample. Thus, SORS delivers a smaller surface signal and a sharper signal from deeper within the sample.

“The [photons] diffuse through the body of the sample…moving sideways and deeper, and then re-emerge at the surface,” says Matousek, and so the measured signal is clear and not restricted to the surface. He goes on to say that a simple analogy for SORS is looking at the sky during the day. “Although we know that there are stars in the sky throughout the day, we cannot see them thanks to the bright light of the Sun. But if an eclipse blocks the light of the Sun, the starts become visible. So with SORS, we are blocking out the surface signal to see the pure signal from the sample body.” The other salient feature of using SORS is that it is always non-invasive.

Quick scan

There is a myriad of applications for SORS. This current one – the INSIGHT100 scanner – uses SORS to scan the products that people carry with them while travelling. The current ban on items of more than 100 ml in hand baggage can only be lifted when airports are able to screen liquids quickly and without opening containers. While X-ray scanners currently do that job, there are a few disadvantages: the main one is that they produce high false-alarm rates, which slows the screening process. The false-alarm rate with the INSIGHT100 is considerably lower at 1% or less. The INSIGHT100 can screen individual bottles in less than 5 s and also provides a high chemical specificity. It can be used for all types of containers in a variety of sizes. The scanner has already passed the stringent testing procedure necessary to allow it to be trialled and is now being used at many major European airports. Matousek also points out that the scanner is to be used in parallel with X-ray scanners. “It complements the existing technology. If something sets off the X-ray scanner, the INSIGHT100 can quickly check and verify it,” he says.

Cobalt Light Systems is also developing SORS technology to be used in many other types of scanners. For example, it is already used in the pharmaceutical industry to test and identify raw materials as they come into a processing plant without needing to open the packaging, and to check in a non-invasive manner if the concentration of active chemical ingredients in a drug is accurate. Other long-term plans include using SORS for in vivo diagnosis of bone disease and cancer detection.