A team of researchers in Europe has shown that the density of large structures can be dramatically reduced, if they are designed using a fractal pattern. The researchers have worked out a way to calculate an optimal “hierarchal structure” built from a certain material so that it can withstand a given load. They claim that using such techniques could help in building highly efficient load-bearing structures that could be used in solar sails, cranes or other lightweight-yet-strong constructs.

A fractal is an object or a structure that is self-similar on all length scales. Fractal patterns are seen in nature at all scales – everything from a single fern leaf that resembles the entire plant, to clouds, snowflakes, blood vessels and cauliflowers shows a fractal pattern. A particular example that inspired this latest work is trabecular bone – the “spongy” bone that is found near joints in the human body. This bone has a sponge-like network of fibres that have a pseudo-fractal pattern, whereby the pattern is almost self-similar across a few scales. This makes the bone strong but light and capable of providing the necessary strength and stiffness.

Build and repeat

A hierarchical pattern – where the same base structure is repeatedly used at different length scales – is already used in architecture to build many large-scale structures. The Eiffel tower or large cranes are good examples of such structures, but such fractal patterns are used in architecture in a rather ad hoc manner, according to the researchers. Now, Yong Mao of the University of Nottingham, UK and colleagues have developed a theoretical framework for building structures where the optimal hierarchical order of the structure depends on the load it needs to withstand. Using this technique, the team constructed such a structure – a simple frame – from a polymeric resin, using a “rapid prototyping technique” – which is an advanced form of 3D printing.

For the first element in their structure, Mao and colleagues simply construct a hollow beam, which they refer to as the “generation-0” element. Different values of thickness and radii of the beam are considered, so that the strongest beam can be built, with the least amount of material. The robustness of this beam is then tested by applying a load along its length and along its axis, to see if it fails across either. “We do this to analyse the failure modes at each local level, so that the structure is not unnecessarily strong at each level…we optimize for what properties are necessary,” says Mao. He explains this further by saying that if a 50 kg table balanced on hollow steel legs it would be about 10 times lighter than one with solid steel legs and just as robust.

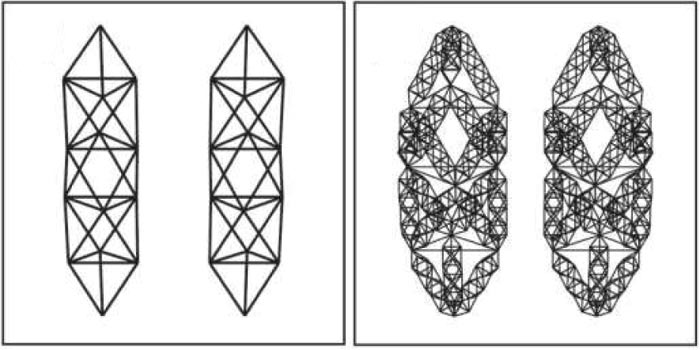

The next step, or “generation-1” structure, is a similar beam on a larger length scale. It is made up of the individual generation-0 beams in a triangular framework (see figure above, left). The generation-2 structure is then made by replacing each beam in the generation-1 structure with a full-scale version of itself, all assembled into a larger triangular frame. This can be repeated for one more level – a generation-3 element – and calculations show that the more hierarchical levels used, the less material that is needed to support a given load.

Strong structures

The team designed a number of different structures. It found, for example, that a crane boom made from generation-1 structures would be 100 times lighter than one made from solid steel. Another more fanciful application would be to use the technique to build the boom of a solar sail. These are large-scale structures in space that, in the future, could harvest solar radiation. The theoretical design for such sails involves booms that would be almost 100 m in length, but only need to be strong enough to withstand solar-radiation pressure. In this case, a steel generation-3 structure would be 10,000 times lighter than a solid beam.

3D printing

A drawback of this kind of fabrication is that imperfections could cause serious problems. “Even a small imperfection at a local scale could have a large impact as there is no extra material that could take the added stress and maybe that is why this kind of fabrication has not been practical to date,” explains Mao, who says that the team is also studying its models to better allow for such errors. But he is convinced that commercial techniques will improve over the coming year, providing the necessary precision tools. Mao also feels that the recently commercialized technique of 3D printing could really benefit the fabrication of these structures. “We could just upload our deferent designs to a program and people could download and print off the structures at home,” he says.

“In theory, a fractal would involve infinite number of generations…but that said, the same kind of complexity could be achieved in the future by assembling more and more generations,” says Mario Castro from Comillas Pontifical University in Spain, who was not involved with the work. “It would have been very intriguing if they had found a way in which these multiple-scale structures would have assembled by self-organization, as it happens in nature, but I think the work is really interesting.”

The work is published in Physical Review Letters.