A specialized polymer film that can generate electricity thanks to its response to moisture has been created by a team of researchers in the US. The composite polymer absorbs minute amounts of evaporated water from its environment, causing it to curl up and down repeatedly. This continuous motion is converted into electrical energy that can be stored in small generators, and eventually could be harnessed to power micro- and nanoelectronic devices, such as remote sensors or actuators, as well as having biological applications.

Ways and means

With the ever-increasing demand for power, scientists are keen to develop alternative ways to harvest energy, especially from the ambient environment. But Mingming Ma, a postdoc at the David H Koch Institute for Integrative Cancer Research at Massachusetts Institute of Technology (MIT), and colleagues were studying something quite different – they were developing a polymeric electrode for medical purposes as a way to simulate muscles for nerve regeneration. “It [the discovery] was not intentional at all,” says Ma. “During our experiments, we found the film expanded when it came into contact with water vapour and realized that this caused its movement.”

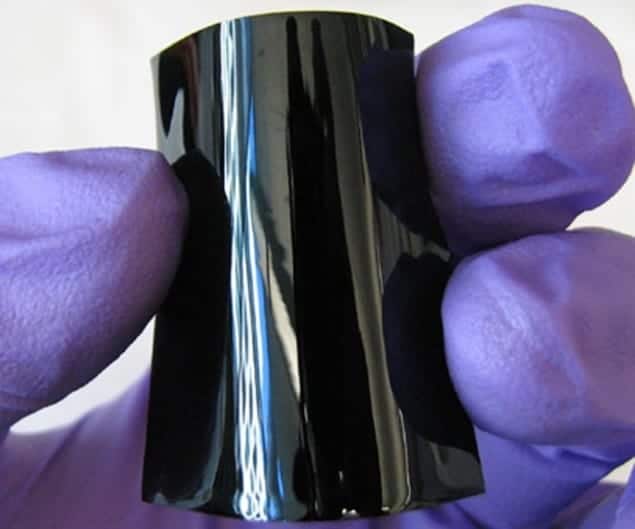

Ma told physicsworld.com that the team’s newly designed 20-µm-thick film is made by interlocking two different polymers to form a network – like a mesh. One of the polymers, known as polypyrrole, forms a hard but flexible matrix that provides structural support. The other – polyol-borate – is a soft gel, and it is this polymer that swells when it absorbs water and contracts when the water is expelled.

Curling mechanics

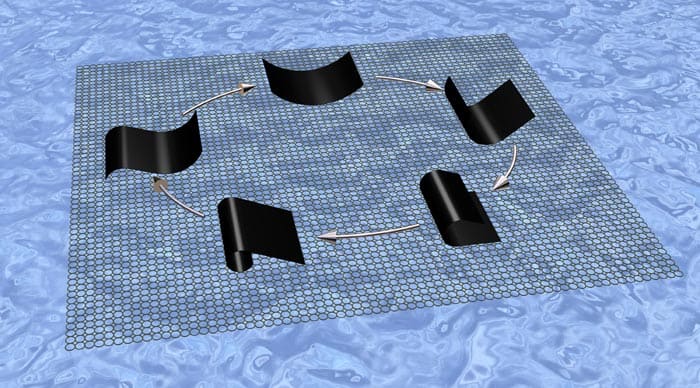

When the material is in an environment that contains even a small amount of moisture, it absorbs some of the water, causing the film to curl upwards. This exposes the underside of the film to air, making it quickly release the moisture and somersault forward. This continuous motion converts the chemical energy of the water gradient into mechanical energy.

Ma is quick to point out that the device does need a water gradient – place the film on a water surface, for example, and it will absorb too much moisture to be able to flip over. “It does not need a lot of water,” Ma says. “A very small amount of moisture is enough.”

Ma says that the team was inspired by the network structure present in the skin of many animals. “They [animals] have two layers – a tough fibre layer and a softer flexible and elastic layer, which together make a sturdy and flexible material,” he says. So the researchers approached designing their film in a similar way, hoping to produce a better water-responsive actuator.

Two better than one

In the past, other water-responsive films have been made only from polypyrrole, which has a much weaker response on its own. “By incorporating the two different kinds of polymers, you can generate a much bigger displacement, as well as a stronger force,” says Liang Guo, another team member.

The team says the film can generate “contractile stress” up to 27 MPa. It claims that a 25 mg film could lift a load 380 times its own weight and transport a load 10 times its own weight.

To turn it into a generator, Ma and colleagues coupled the polymer film to a piezoelectric material – which converts mechanical stress to an electric charge – to generate an average power of 5.6 nW. This energy can be stored in capacitors to power ultra-low-power microelectronic devices such as temperature and humidity sensors. It could also power microelectricalmechanical systems (MEMS) or even smaller devices such as nanoelectronics.

Big ideas, small films

Other applications could include attaching the film to clothing worn while exercising, where sweat evaporating from the body could power small devices. Ma even suggests placing it above or near a large body of water, such as a lake, to generate electricity. But this would involve greatly increasing the mechanical-to-electrical energy conversion to make it much more efficient. “We want smaller films to power larger devices. For this we need a better piezoelectric material developed for the purpose,” explains Ma. The researchers plan to investigate this, as well as other applications for their film, in the coming months.

The research is published in Science.