The world’s most powerful heavy-ion accelerator, the Facility of Rare Isotope Beams at Michigan State University, exploits transistor-based power amplifiers to generate beam intensities of up to 400 KeV

In May 2022 the long-awaited Facility for Rare Isotope Beams (FRIB) opened its doors to scientists who are eager to experiment with exotic atomic nuclei that in many cases have never before existed on Earth. The FRIB, built over the last eight years at Michigan State University in the US, is expected to shed new light on fundamental questions in nuclear physics, including how most of the elements in the universe are created in stars and supernova explosions, while also enabling important innovations in fields as diverse as medicine, materials discovery, and environmental science.

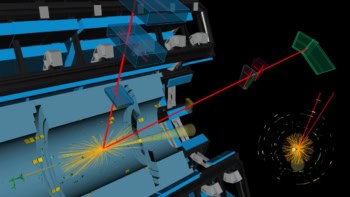

All of this will be made possible by the world’s most powerful heavy-ion accelerator, capable of propelling atomic nuclei of any stable element to half the speed of light. By colliding ions with energies of up to 200 MeV with a target, the FRIB promises to produce rare isotopes at a rate orders of magnitude higher than is possible at other similar facilities, while also providing scientists with access to isotopes that have not yet been synthesized or detected here on Earth.

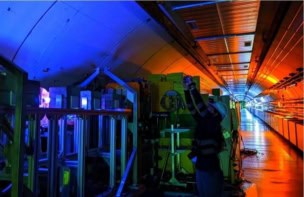

The accelerating power of the facility is achieved with 324 superconducting radio-frequency cavities distributed around a 500 m linear structure. Inside these resonators a low-level RF signal is boosted by a series of power amplifiers from a signal strength of just a few milliwatts up to a maximum beam intensity of 400 kW – about 1000 times greater than the accelerator the FRIB is designed to replace, the National Superconducting Cyclotron Laboratory.

Unlike its predecessor, and most other existing large-scale facilities, the FRIB exploits solid-state power amplifiers to accelerate the beam. “Over the last few years there have been big improvements in transistor technology, which means that each chip can deliver more power,” says Marcus Lau of TRUMPF Hüttinger, a power-electronics specialist that designed and produced the power amplifiers for the FRIB. “At frequencies from around 80 MHz to those approaching the gigahertz regime, it is possible to obtain more than 1 kW from each transistor.”

That improvement in power output has made solid-state systems a viable alternative to traditional vacuum-tube technologies, such as klystrons, active output tubes and tetrodes. These established devices can generate a few megawatts of power from a single tube, but reliability can be an issue: their performance gradually deteriorates from the moment they are switched on, reducing the amount of electrical power that is converted into a microwave signal. They also introduce a single and unpredictable point-of-failure into the system, occasionally forcing a facility to shut down for repairs during the time allocated to scientific experiments. “Both technology suppliers and end users are moving away from tube technology,” says Lau. “Both the initial investment and the operating costs have increased, particularly for klystrons, and it’s becoming more difficult to access service and maintenance.”

In contrast, the power delivered by solid-state amplifiers remains constant throughout their lifetime. The availability of the accelerator for scientific experiments can also be maximized by building redundancy into the design, with TRUMPF Hüttinger exploiting a fully modular architecture that integrates multiple transistor modules into rack-mountable power-amplifier units. “We don’t operate the units at 100% of their capability. If one transistor fails, we can compensate with other amplifiers in the system while the accelerator is still running, ” explains Lau. “We know the mean time between failure for the devices, so we can calculate the redundancy that should be built into the system to enable the power amplifiers to operate throughout an experimental run.”

In the worst-case scenario, an entire power-amplifier unit can even be replaced while the facility is still operating – a process called “hot swapping”. Each of the transistor modules, or “pallets”, are also continuously monitored during operation to enable predictive maintenance. “It’s really an advantage to see the status of the different pallets,” comments Lau. “If we see any deviations, for example in the power emission, we can choose to exchange an amplifier unit during scheduled downtime rather than having it fail during the next operating period.”

The engineers at TRUMPF Hüttinger have been developing the power-amplifier system for the FRIB for a number of years. The contract was originally awarded to HBH Microwave, a company founded in 1999 to develop microwave systems for radar and communications, but also capable of developing transistor-based amplifier technology for particle accelerators, and it was acquired by TRUMPF Hüttinger in January 2020. “Historically TRUMPF Hüttinger has focused on producing power generators for driving CO2 lasers and other electronic products,” explains Lau. “The merger with HBH Microwave allowed us to extend our product portfolio into high-frequency power electronics, and gives our ongoing development of power amplifiers for particle accelerators the backing and commitment of a major technology supplier.”

The modular design of the TRUMPF Hüttinger system offers maximum flexibility for large facilities like the FRIB, since it allows different amplifier units to be combined together to meet the power and frequency demands of each type of resonator. For the FRIB the amplifiers also need to be protected from energy that is reflected back into the electronic units, which in some extreme cases can reach four times the power emitted by a single pallet. To meet this requirement the company’s engineers designed a circulator circuit to isolate the transistors from the reflected signal, but they found it challenging to make the circulator work properly at the FRIB’s lowest operating frequency of 80.5 MHz. “At this frequency small changes in temperature affected the performance of the circulator,” explains Lau. “Within the project we developed software to track the optimized performance of the circuit, which made it possible to adapt its operation at low frequencies just by applying a voltage.”

To check that the transistors could withstand the intense reflected energy, each amplifier unit was subjected to rigorous burn-in tests before they were sent for installation at the FRIB. A small rack-based set-up was built to allow different power-amplifier units to be combined together, and then a phase shifter was used to replicate the reflection conditions inside the accelerator. For the “worst-case phase”, equivalent to the most reflected power, the emission from the power amplifiers was tested continuously for at least 24 hours.

Close communication with the project team was essential throughout the project, all the way from the initial design proposals through to final installation of the power-amplifier units. “We have bi-weekly meetings for each of our ongoing projects, which allows us to get feedback from the customer and to talk about any particular issues,” says Lau. “There is always something we haven’t thought about, and that needs to be adapted, even if it’s something simple such as whether the cooling water is supplied from the top or the bottom of the system.”

That ongoing dialogue enabled the FRIB project team to install and configure several hundreds of amplifier units for powering the different types of resonator deployed in the accelerator. “They were engaged and familiar with the system, plus we had sent them the first evaluation units,” adds Lau. “The intense exchange we had with the FRIB engineers helped the whole project to stay on time and within budget.”

TRUMPF Hüttinger is now applying its know-how in high-frequency power electronics to several other large-scale projects, driven in part by ongoing upgrades at synchrotron light sources around the world. Longer term, Lau sees an opportunity for developing turnkey solutions for medical applications that rely on accelerator-based systems, including the growing trend towards proton and ion-beam therapy. “It’s an expanding field and it’s definitely moving towards transistor technology,” he says.

Such innovative approaches generally don’t happen in isolation, which has prompted TRUMPF Hüttinger to organize a conference to explore the use of different accelerator systems for applications in science, industry and medicine. Taking place on 15–16 November 2022 in Freiburg, Germany, the Power Amplifiers for Particle Accelerators (PA2) conference aims to provide a forum for both end users and a range of industry partners to discuss emerging technology solutions as well as future directions for research and innovation. “We want to bring industry together with the scientific community,” says Lau. “In my experience it is always important not to stay in your own field but to talk to other experts to seed new ideas. We hope it will allow a fruitful exchange.”