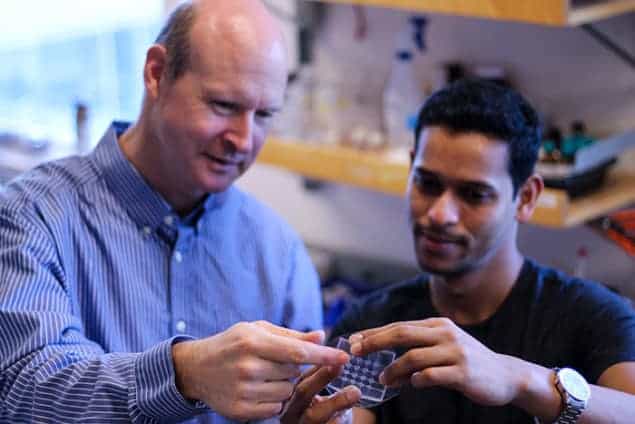

A flexible touch sensor that can distinguish between being touched and being stretched has been developed by researchers in Canada. The devices could be integrated into clothing and could even be used to create “skin” for robots.

Touch sensors are ubiquitous and are used in a range of technologies from smartphone screens to robotic limbs. Researchers are now looking at creating flexible, stretchable sensors that can be used where traditional sensors are not suitable. This raises a challenging problem: if a touch sensor is deformable, how does it know whether it is being touched or stretched? Mirza Saquib Sarwar, John Madden and colleagues at the University of British Columbia (UBC) now think they have an answer, with a sensor with a capacitance that increases when you stretch it and decreases when you touch it.

Delicate touch

Capacitive touch sensors are used on applications like smartphone screens for several reasons. They are very sensitive, requiring a delicate touch rather than a hard press. They can detect multiple fingers touching the screen in different places – essential for many functions of smartphones such as allowing the user to zoom in by moving two fingers apart. The sensors generally comprise a grid of capacitors etched onto glass. Bringing a finger – or a conductive stylus – near one of the capacitors distorts the surrounding electric field, reducing the capacitance.

Several groups have produced deformable versions of the capacitive touch sensor. In 2011, for example, researchers at Stanford University in California developed a pressure-sensitive polymer embedded with two networks of carbon nanotubes. Pressing on the device brings the networks closer together, increasing the capacitance. However, stretching the device does the same, so these devices have difficulty distinguishing stretch from touch.

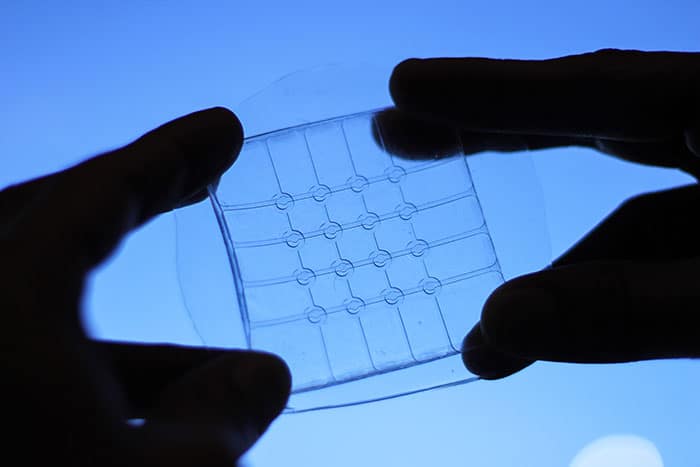

In the new research, the UBC team used two sheets of the dielectric, elastic polymer PDMS embedded with channels of hydrogel parallel to each other but perpendicular to the channels in the other sheet. They made the hydrogel from salt water, allowing it to conduct electricity by the flow of ions. This allows them to create flexible, transparent electrodes in each sheet. Between the two sheets, the researchers embed a third layer of plain PDMS. This electrically isolates the sheets and creates a grid of capacitors where the electrodes cross. Holding the top and bottom layers at different potentials establishes an electric field between them.

Charge develops on your finger because it starts acting as a third electrode

Mirza Saquib Sarwar, UBC

Previous designs for elastic touch sensors have allowed the conductive pathways to pass directly over one another, effectively creating a grid of parallel plate capacitors. However, in the new research, the team intersperses the channels in one sheet with discs and those in the other with loops. Seen from above, the discs sit inside the loops, so the conductive layers are not directly on top of one another. Therefore, instead of passing vertically down through the dielectric layer between the sheets, the electric field spreads much more widely and escapes into the air above the sensor. When a finger approaches, it disturbs the electric field, reducing the capacitance between the plates: “Charge develops on your finger because it starts acting as a third electrode,” explains Sarwar, “So now you have three capacitors – one between the two electrodes and one between each electrode and your finger.”

The researchers demonstrated that the device could still sense touch when being stretched or bent. “When you stretch it, the capacitance goes up,” explains Sarwar, “When you touch one single point, you see the capacitance going down. From that, you can tell that you’ve lightly touched one point while you’re actively stretching it.”

Swiping finger

The sensor could detect multiple fingers simultaneously and track the swiping motion of a finger – potentially allowing smartphone screens and trackpads. The researchers believe the techniques used to make their sensor are amenable to mass production and the materials are cheap and readily available. Sarwar is confident the technology exists to produce pixels with sub-millimetre size, allowing a high-precision sensor. He mentions several possible applications such as wearable technology: “We want to break through the watch idea, so that the whole wrist band can become an interactive surface,” he says. “Also, it could be useful in robotic skin because you’re able to mould it into whatever shape and size you want.”

Danilo De Rossi of the University of Pisa in Italy is impressed, but not stunned, by the research: “It’s nothing particularly new, but the combination of things is certainly worth reading and worthy of attention,” he says.

The new sensor is described in Science Advances.