Displays, spectroscopy and laser welding are just some of the sectors enjoying green growth in the optoelectronics industry. Richard Stevenson investigates

Green photonics is booming according to the US-based Optoelectronic Industry Development Association, which reckons this incredibly diverse global industry netted a colossal $57.9bn (€40bn) in 2008. In 2021 this is expected to rise to nearly $300bn and encompass just over half of the optoelectronic industry, says the association.

This rapid growth looks set to make the world a better place. For example, it promises to aid increased solar-cell deployment to boost clean energy generation, cut greenhouse-gas emissions and pollution, and ultimately lead to a more environmentally sustainable approach to producing electricity. Another consequence of the green photonics revolution could be improved public health, with light-emitting diodes (LEDs) starting to purify water and improve the treatment of skin conditions.

The area where green photonics is tipped to generate its biggest sales is flat-panel displays. Recently, TVs with liquid-crystal and plasma displays have nudged up household electricity bills. These technologies do not need any more juice than the cathode-ray tube per unit of screen area, but their screens are often larger, making them more power hungry. Customers can save energy by investing in laser-projection TVs: for 60–65 inch screens, plasma and liquid-crystal display (LCD) TVs typically consume 525 W, while an equivalent based on projection technology requires just 135 W. A cheaper green option is also tipped for huge growth: an LCD screen backlit with an array of LEDs rather than the conventional cold compact fluorescent lamp. This cuts electrical consumption by up to 60% for a 42 inch TV, according to Chinese screen manufacturer Chi Mei Optoelectronics.

Revolution in lighting

LEDs will also drive a revolution in general lighting. LED devices on sale today can deliver up to twice the efficiency of a compact fluorescent, and unlike this incumbent they are free from mercury. High prices are holding back sales – a 40 W equivalent with a good hue retails for $20 or more – but prices could plummet to $5 by 2014.

A robust evaluation of the environmental impact of any lighting source must consider the energy required for product manufacture. For LEDs, compact fluorescents and incandescents this equals about 2% of energy used during the entire life cycle, according to calculations made by German firm Osram Opto Semiconductors. “But you have to compare the lifetimes,” says Osram’s Berit Wessler. “LED lamps last 25,000 hours – two-and-a-half times as long as a compact fluorescent and 25 times that of an incandescent,” he explains.

An LED that is on for 4 hours a day should last 15 years, which means that lighting sources need no longer be thought of as consumables. This has already led developers of LED products to blur the distinction between the lamp and the light fixture – or luminaire. “At some time in the future people will buy luminaires, and due to the extremely long lifetimes they will not exchange the lamp anymore, because the LEDs are connected directly to the luminaires,” says Wessler.

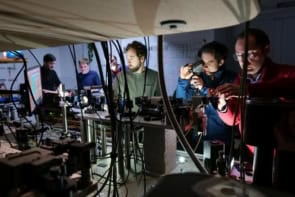

Lightweight spectrometers

Photonics can also help to create a greener world by monitoring air quality. One company making such a product is Ocean Optics of Dunedin, Florida, which builds lightweight spectrometers that were widely used during the 2008 Olympics. “You can put an optical sensor inside a factory, traversing the smoke stack, and monitor emissions – we were a big part of that in Beijing,” says Jason Eichenholz from Ocean Optics.

Eichenholz says that one of the strengths of spectroscopy, compared with more traditional technologies for atmospheric monitoring, is the small size. “In the UK we are working with customers to do mobile sensing. They are able to put something that used to be the size of a small trailer into something the size of a briefcase,” he says. The spectrometer can be fitted on the top of a car, enabling comparisons of sulphur-dioxide and nitrous-oxide levels on different parts of the road.

To reduce emissions produced by cars and improve manufacturing throughput, Swedish car maker Volvo has been replacing its resistance spot-welding systems for assembling car body frames with laser-based versions. The optical approach cuts downtime because of greater reliability, and less metal is scrapped thanks to less variation in weld quality.

Reducing carbon-dioxide emissions

Volvo’s Johnny Larson says it is possible to shave a few kilograms off the weight of a car’s metal frame by optimizing its design for a laser process. This has knocked up to 2 kg off the XC60, and for every one of these models that clocks up 100 000 km, 24 kg of carbon-dioxide emissions will be saved.

Lighter cars that are less polluting, air that is monitored for public health, and LEDs that power more efficient displays and lighting are sure to drive up revenues in green photonics. But making more money will not be the only outcome – a better quality of life for all of us is also on the horizon.