From the Egyptian pyramids to The Pentagon in Washington DC, limestone has long been one of the most popular materials for ornate buildings and monuments. But this rock’s aesthetic qualities and workability come at a price – it can be vulnerable to degradation by natural weathering, air pollution and other processes.

New research by scientists in Spain and Greece might provide a new way of preserving limestone architecture for future generations. The group has created a nano-composite doped with quantum dots, which can be applied to reinforce limestone structures while providing a way of monitoring the changes.

When consolidating historic architecture, you want durability and chemical compatibility, without changing its aesthetic features. Traditionally, limestones have been treated using limewater, a common name for a dilute aqueous solution of calcium hydroxide. Limewater can create a durable seal, but it does not tend to penetrate deeply into the rock. Also, calcium hydroxide has a limited solubility in water.

An alternative developed the past decade are “nanolimes” – calcium hydroxide nanoparticles dispersed in water or organic solvents. The tiny size of nanoparticles enables them to penetrate deeper into stone, while the increased specific surface area can enhance the carbonation process. Indeed, it is the calcium carbonate created in this process that cements the original limestone structure, not the nanoparticles themselves.

Nanolimes are still a relatively young technology so there is uncertainty over how they will perform over long time periods. In some cases, nanoparticles have been known to migrate back to the surface as the solvent evaporates. So, when applying nanolimes in the real world it is important to monitor their performance over time.

Nanolimes with a twist of quantum dots

To help with monitoring, a new type of nanolime has been created by a team led by Javier Becerra Luna from the Universidad Pablo de Olavide in Spain. Dubbed “Nanorepair UV”, the material takes advantage of the optical properties of quantum dots. These are tiny pieces of semiconductor just a few nanometres across that are sometimes described as “artificial atoms” because they absorb and emit light at specific wavelengths.

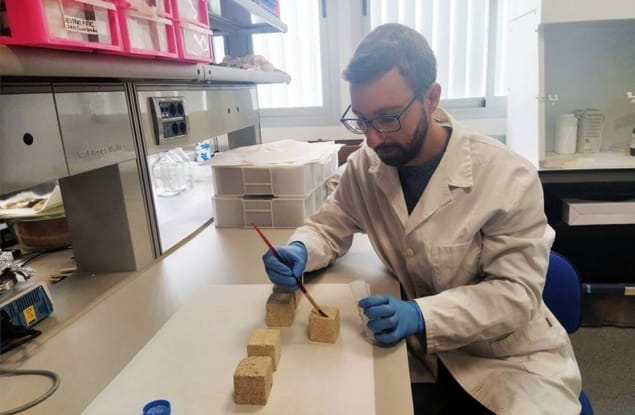

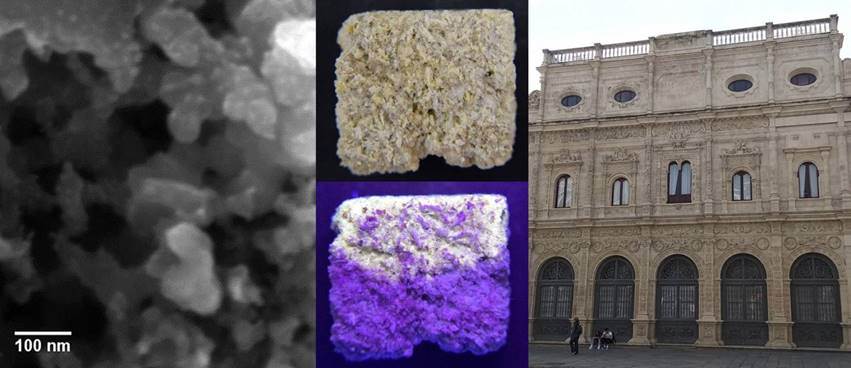

Becerra’s nanolime comprises calcium hydroxide nanoparticles doped with zinc oxide quantum dots, which act as markers. When illuminated with UV light, the quantum dots emit fluorescent light, highlighting the newly formed limestone against the original structure. In practice, conservation workers would remove a small sample from an inconspicuous part of a monument to establish how deeply the consolidant has penetrated and how it is performing.

“The major technical challenge was creating a nanocomposite and not a mixture of two different nanoparticles. It is a key point that the quantum dots are posed on the calcium hydroxide, so we can measure the real penetration depth of the treatment,” Becerra told Physics World.

In the group’s latest study, the prototype product was tested against three commercially available consolidants. Two of the alternatives are silica-based, while the other uses calcium hydroxide nanoparticles but without the quantum dots.

All four products were tested on samples from two separate quarries in the Cadiz province of southern Spain. Limestones from these sites were used in the cathedrals of Seville and Cadiz and other important Spanish buildings. Historically, limestone has been widely used throughout southern Europe and northern Africa due to the large amount of calcareous geology found around the Mediterranean Sea.

Describing their findings in Applied Clay Science, the researchers conclude that the two nanolime products had higher effectiveness and better durability than the silica treatments. However, Nanorepair UV had the added advantage of the quantum dots. Shining a UV light on rock cross sections revealed penetration depths of up to 0.8 cm.

A dash of salt

Out in the real world, one of the biggest perils for limestone monuments is weathering by salt crystallization. Water entering the pore network of a stone may contain salts in solution, which can crystallize as water evaporates. This creates pressure inside pores that can lead to micro-fractures, eventually compromising the rock’s surface structure.

In the study, treated samples were subjected to accelerated salt crystallization by being soaked in a sodium sulphate hydrate and baked in an oven multiple times. Sample surfaces were then peeled using a standard sticky tape to reveal the extent to which they had been compromised. The Nanorepair UV-treated sample fared better than the other nanolimes. The team attributes this to the presence of silane in Nanorepair UV, which is included to stabilize the quantum dots.

The results have impressed Roberta Fanatoni, an applied scientist at Italy’s National Agency for New Technologies, Energy and Sustainable Economic Development, who was not involved in the research. “A single product was able to overcome distinct limitations on limestones of the other three commercial products,” she said.

Fanatoni also points out that the presence of zinc oxide might provide an additional benefit of acting as a biocide, reducing stone degradation due to biological processes.

Muons reveal hidden void in Egyptian pyramid

According to Carlos Rodríguez-Navarro, a geologist at Spain’s University of Granada, the Mediterranean basin is full of monuments build from very similar limestones. “You can see very nice examples of monuments built with calcarenite in Sicily, Puglia or the Greek Islands. So, the potential applications of this novel treatments are likely limitless.”

A specialist in cultural heritage, Rodríguez-Navarro does caution, however, that the need to remove samples from historic stonework would be discouraged in lots of real-world situations. He also points out that lab tests can never provide 100% guarantee of how a treatment will behave in the real-world.

Becerra’s group has patented Nanorepair UV and they are currently looking for industrial partners to scale up production. They are in the process of testing the nanolime on real samples of Roman mortars and they are also studying the use of nanoparticles for other cultural items including books and bones.