A new three-dimensional imaging system uses multimode optical fibres (MMFs) rather than traditional bulk optics, paving the way for applications in medical imaging. The system can scan a scene at a rate of nearly 23,000 points per second over depths of up to several metres beyond the end of a roughly 40 cm-long fibre. It can also record near real-time videos at frame rates of nearly 5 Hz, making it competitive with standard, camera-based fibre-optic endoscopes of the type routinely employed in biomedical research for diagnosing disease and in surgery.

As their name implies, MMFs are a type of optical fibre designed to carry multiple rays of light or light modes at the same time. Each of these rays or modes are reflected at slightly different angles inside the core of the optical fibre, which is usually made of glass and has a diameter in the 50–100 micron range for the light-carrying component. Because the modes tend to disperse as they travel down such fibres, MMFs are typically used to transmit light across relatively short distances. This makes them very different from single-mode fibres, which also contain a glass core (albeit a much smaller one, at less than 10 microns across) through which light can be transmitted at high speeds over longer distances with little modal dispersion.

High-speed wavefront shaping

Creating three-dimensional imaging platforms using MMFs has proved challenging since the optical signals are prone to scrambling, which distorts the resulting images – an effect known as aberration. A team led by Miles Padgett of the University of Glasgow, UK, together with colleagues in Germany and the Czech Republic, has now managed to control this effect thanks to a technique known as high-speed wavefront shaping, synchronized with a sub-nanosecond pulsed laser source to correct aberrations. This approach involves shaping the light fields entering the MMF using a digital micromirror device operating at 22.7 KHz.

Ultrashort visible light pulses made easy

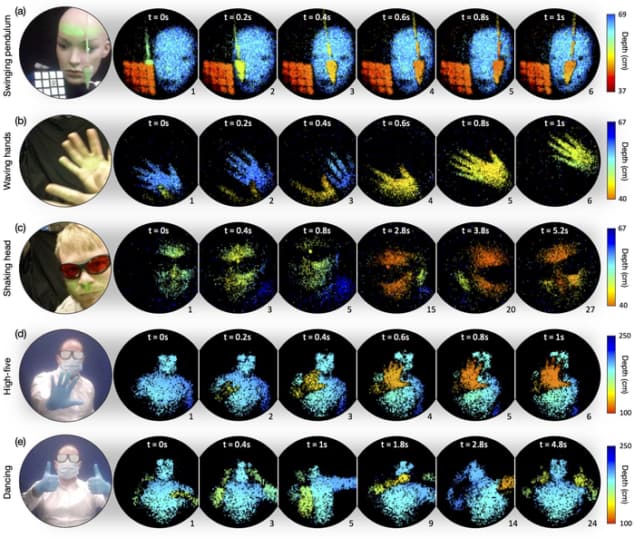

The researchers then raster (that is, scan in a pattern of parallel lines) the pulsed laser source across the sample being imaged, delivering a single laser pulse to each of 4200 points in just 200 ms. A second fibre placed next to the illumination fibre then collects backscattered light. This collection fibre has a larger core diameter (500 mm) to increase the amount of light collected and thereby extend the working distance of an endoscope based on this technique, the researchers explain. Finally, the return signal from each image pixel is coupled directly to a device known as an avalanche photodiode and converted to a “time-of-flight histogram”, which is referenced to the time that the outgoing light pulse entered the illumination fibre.

Padgett and colleagues say that as well as biomedical imaging, their prototype time-of-flight-based 3D imaging system could have applications in remote inspection. Reporting their work in Science, they now plan to improve the system’s depth resolution to less than 1 mm and increase its image depth to more than 5 metres. “We also hope to reduce the time it takes to [perform] the fibre calibration,” Padgett tells Physics World.