Researchers have used materials known as transition metal dichalcogenides to make ultrathin, flexible solar cells with a power conversion efficiency (PCE) of 5.1% – a record for cells made from this type of material. Though this efficiency is far below that of standard silicon solar cells, the super-light nature of the new cells means they could be employed in mobile applications such as self-powered wearable devices and sensors as well as drones and lightweight electric vehicles.

Semiconducting transition metal dichalcogenides (TMDs) such as tungsten diselenide (WSe2) show much promise for use in optoelectronics devices that need to efficiently absorb sunlight over a wide range of wavelengths. Because these materials are layered (two-dimensional), they can also be made into thin films for low-power electronic circuits and flexible displays, sensors and even flexible electronics that can be coated onto a variety of surfaces. This is why they are touted as a promising alternative to silicon, which despite being today’s most widely-used solar material is much too heavy, bulky and brittle for these applications.

The problem is that most TMD solar cells made so far have struggled to exceed PCEs of around 2%, compared to silicon’s PCE value of nearly 30%. One of the reasons for this is related to the way TMD cells are transferred onto flexible, supporting substrates during fabrication – a process that often damages the TMD layer, reducing its performance.

A team led by Alwin Daus (then at Stanford University in the US, and now a senior researcher at RWTH Aachen University, Germany) and Koosha Nassiri Nazif, a postdoctoral researcher at Stanford, got around this by devising a new method that allows the TMDs to be completely embedded in the substrate, thereby providing a flat surface for a transparent graphene (a sheet of carbon just one atom thick) top electrode. This, combined with a capping layer, makes the TMD solar cells more durable.

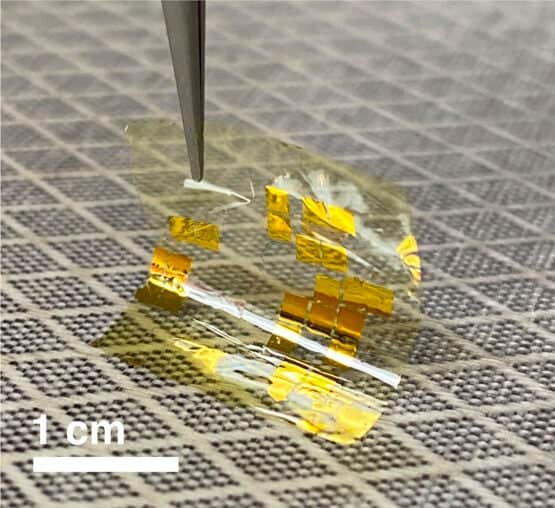

The new cells are less than six microns thick, lightweight, flexible, stable and robust for long periods of time, the team reports. They are also biocompatible since – unlike cells made from high-performing perovskites or lead sulphide quantum dots – they contain no toxic elements. Therefore, they could be used in wearable electronics that are worn next to the skin.

High power-to-weight ratio

As well as its PCE of 5.1% – a figure the team say could be increased to 27% with optimization – the new device also has a power-to-weight ratio 100 times greater than that of any other TMD solar cell developed to date. This ratio is important for mobile applications like drones and electric vehicles, explains Nassiri Nazif, co-lead author (with Daus) of a paper in Nature Communications describing the work. “What is more, the specific power – a measure of electrical power output per solar cell unit weight – of the prototype is 4.4 W/g, a figure that compares well with other established thin-film solar cells, such as CdTe, CIGS, III-V and silicon,” he tells Physics World. “Again, this value might be increased – by as much as 10 times – to reach 46 W/g.”

In search of new solutions for cheap and stable solar cells

Looking forward, the Stanford team says it now aims to improve the optical and electronic design of the flexible WSe2 cells to increase their PCEs. One possible strategy could be to apply a thicker anti-reflection coating made of Molybdenum oxide (MoOx) to the TMD. Indeed, preliminary computer simulations have revealed that simply increasing the thickness of this coating to around 70 nm could boost the light absorption in the ultrathin WSe2 to 80%.