Multi-photon lithography and optical tweezers are among the tools driving a new generation of 3D printing that will allow multifunctional devices to be fabricated in a single processing step, explain Richard Hague, Martin Baumers, Chris Tuck and Ricky Wildman

The technique of 3D printing, more accurately known as additive manufacturing, has enjoyed extensive coverage in the media in recent years. Consumers will play an increasing role in manufacturing the products they use regularly, it is often suggested, perhaps even designing those products themselves. One frequently cited scenario involves consumers using free Web-based packages or mobile-phone photogrammetry applications to specify a design, then submitting it to a commercial 3D-printer operator who will carry out the manufacturing step and ship the product directly to them.

To a limited extent, this picture is already a reality. The commercial availability of low-cost 3D printers over the past five years has certainly allowed consumers to operate home-based manufacturing technology. Such low-cost platforms, which have come about because of the expiry of patents covering earlier prototyping systems, work on a principle called “filament extrusion”, in which a thin polymer thread held at a temperature close to its melting point is squeezed out from a small hole and deposited in raster fashion on a substrate. Consumers are also beginning to take advantage of commercial 3D-printing services, which use established industrial laser-based systems that generally work on the “powder bed” principle: a high-power laser scanned across an extremely thin bed of powder fuses a slice of a 3D object together, and the process is repeated to build up a volume.

Consumer devices bear little resemblance to their industrial additive-manufacturing counterparts, however. They tend to be able to deal only with a handful of extruded thermoplastic materials and – despite the “you can make anything” hype – are greatly limited in the size, resolution and complexity of the parts that they can produce. Indeed, low-cost 3D printing makes up only a relatively small part of the overall 3D-printing industry: around 6% by revenue.

At the more established industrial end of the spectrum, however, the variety of printable material types has increased to include polymers, metals and ceramics. Such single-material addition is already an established manufacturing process in many sectors, including the hearing-aid industry, which manufactures millions of custom hearing-aid shells annually using stereolithography. Selective laser-melting technology has also recently been adopted by GE Avionics to produce metallic components in aero engines, while polymer laser-sintering technology is allowing firms such as FreshFiber to produce customized and complex designs for smartphone covers.

Researchers are now exploring 3D-printing techniques that not only allow complex objects to be manufactured at low cost from almost any material, but will also enable objects with different functionalities to be printed in a single step. This next generation of additive-manufacturing technologies, which is rooted in advanced material-deposition systems and optical techniques, is being investigated by the Engineering and Physical Sciences Research Council’s Centre for Innovative Manufacturing in Additive Manufacturing at the University of Nottingham in the UK, which is undertaking internationally leading work in multifunctional 3D-printing research.

Beyond the hype

It might seem that 3D printing is a novel technology. In fact, the underlying principle – in which raw material is deposited layer by layer without the need for moulds, tools or dies – was first commercialized almost three decades ago. Originally developed for rapid design studies and prototyping, the earliest 3D-printing systems used an ultraviolet laser to selectively photopolymerize a liquid photocurable monomer resin, repeating the process layer by layer until the part is completed. Successive innovations since then have led to the spectrum of additive systems we know today, including the low-cost extrusion-based machines as well as industrial systems based on fusing powders using infrared lasers.

As one of the leading research groups in this area, the 3D Printing Research Group at Nottingham is going beyond single-material 3D printing. Rather than incrementally improving existing single-material approaches, we are working on the next generation of systems capable of depositing multiple materials all at once. Doing so will enable the technology to leap beyond simple structural applications and allow the delivery of entire functionalized systems, such as 3D circuitry, drug-delivery systems and even biological tissue, within a single processing step.

We expect that multifunctional 3D printing will be commercially available within the next 15 years, but there are major technical challenges ahead

We expect that multifunctional 3D printing will be commercially available within the next 15 years, but there are major technical challenges ahead. These range from the accurate and reliable simultaneous deposition of different materials to the design of components and how best to integrate different materials for a given function. The variety of disciplines involved reflects the vastly different functional properties that could be printed directly into structural products: electrical circuitry, optical tracks, embedded sensors, energy sources, displays, antennas, chemical agents and even biologically active structures are just some of the many targets. A large part of research in this area is therefore focused on the search for functional 3D-printing materials.

New design approach

The first challenge, however, is to create a design methodology that enables us to integrate printed structures with lattices that contain functional components. Constraints within traditional manufacturing approaches, such as injection moulding or CNC machining, mean that, in general, it is not possible to fabricate the optimal shape for a given task. Instead, we are turning to algorithms that seek out the optimal shape or composition for a device taking into account weight, aesthetics and functionality in a single processing step.

A promising technique for depositing structural materials, especially engineering polymers, is drop-on-demand ink-jetting. This can take two forms: directly jetting a material that is suspended or in solution; and “reactive jetting”, whereby a monomer and catalyst are deposited separately and polymerization occurs in situ during the manufacturing process. This minimizes waste, reduces the need for solvents and opens up a wider range of materials that can be printed. Our group has printed nylon using this approach, but the current focus is on engineering materials that include polymethyl methacrylate, polyimides and polyurethane.

We are also investigating materials and deposition processes for conductive and dielectric systems, including highly novel research into the ink-jetting of metals with a melt temperature up to 1500 °C. This work, to be carried out in collaboration with the Netherlands-based manufacturer Océ, can potentially overcome limitations with conventional printed-electronics materials (such as their low conductivities), which currently rely on inks that have been loaded with nanoparticles of active materials such as silver.

One of the most exciting developments in this field is the creation of multifunctional structures at the nanoscale, which demands further improvements in the deposition resolution. At Nottingham we are developing a multi-photon lithography system that can produce arbitrary 3D structures of the order of 100 nm for advanced micro- or nanoscale applications, and using optical-tweezer technology to functionalize the structures deposited (see box). By coupling these two systems we can open the door to new nanoscale devices and structures, for example by providing the sensory input for embedded data-processing capability.

Dial-up medicine

Over the coming years multifunctional 3D printing will move beyond fundamental research towards new manufacturing systems. Currently, we are at the stage of understanding the fundamental principles and challenges of multifunctional 3D printing, but it is clear that we need a joined-up approach between numerous disciplines – including physics, chemistry, optics, electronics, materials science, biology and pharmaceutics. To this end, we are working with the School of Pharmacy at Nottingham to explore the 3D printing of pills and multiple therapeutics designed to release drugs at a rate that is personalized to the patient. This would lead to a radically decentralized business model in which drugs or implants could be distributively manufactured. It is envisaged that a medical practitioner would be able to “dial up” a treatment that is then made to a bespoke specification in a room next door, offering personalized care to patients at the point of need.

Multifunctional 3D printing promises genuinely new kinds of manufacturing processes with advanced capabilities, and ultimately a new generation of optimized and highly functional products. Supported by innovative business models, these products will set new standards in performance, efficiency and user-friendliness.

Optical techniques carve nanoscale features

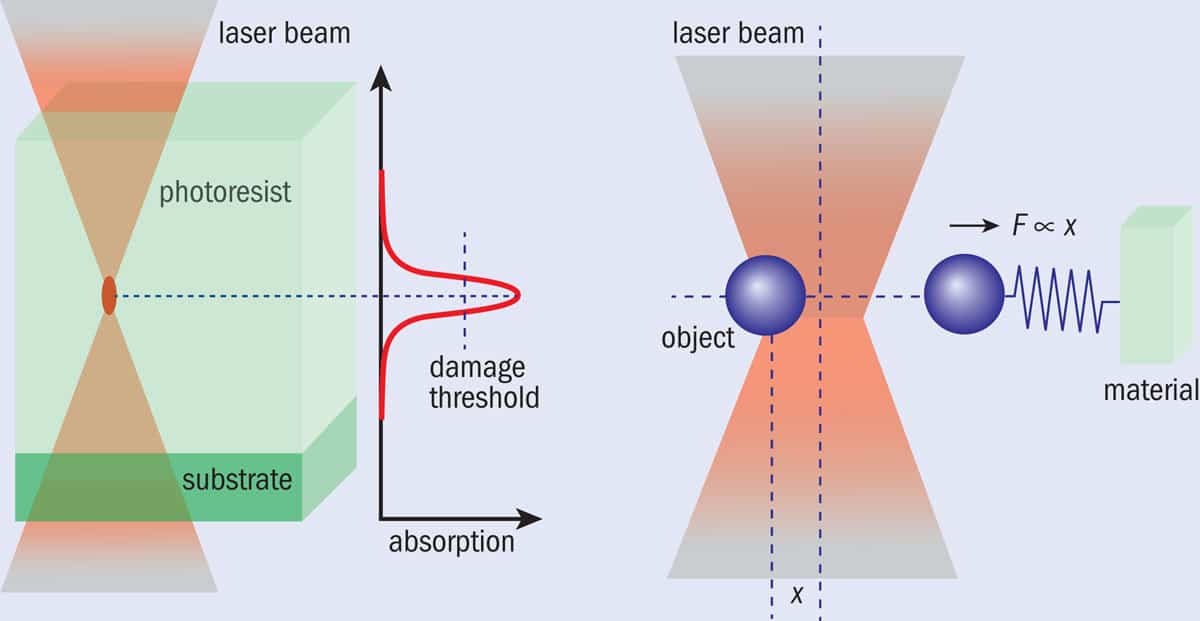

Printing functional nanoscale devices calls for sophisticated optical techniques. Two-photon polymerization (left) allows a finer resolution than is possible with more common single-photon absorption methods. By using photons with half the energy required to drive a polymerization reaction, the two photons need to be absorbed within a very short timescale. Because this process is proportional to the square of the intensity of photons incident on the target, only in the most focused regions of the incident light – when using a high numerical aperture and a femtosecond-pulsed laser – will two-photon absorption occur, therefore resulting in high resolution and feature sizes of the order of 100 nm. By coupling this set-up with an optical-tweezer arrangement, whereby very small forces can be exerted on an object through the focusing of a laser beam (right), larger micron-sized objects can be drawn into the vat of material and encased within a matrix or attached to a surface. This offers the potential for functionalizing a surface or a material by combining it with particles prepared separately and then brought together.

Printing functional nanoscale devices calls for sophisticated optical techniques. Two-photon polymerization (left) allows a finer resolution than is possible with more common single-photon absorption methods. By using photons with half the energy required to drive a polymerization reaction, the two photons need to be absorbed within a very short timescale. Because this process is proportional to the square of the intensity of photons incident on the target, only in the most focused regions of the incident light – when using a high numerical aperture and a femtosecond-pulsed laser – will two-photon absorption occur, therefore resulting in high resolution and feature sizes of the order of 100 nm. By coupling this set-up with an optical-tweezer arrangement, whereby very small forces can be exerted on an object through the focusing of a laser beam (right), larger micron-sized objects can be drawn into the vat of material and encased within a matrix or attached to a surface. This offers the potential for functionalizing a surface or a material by combining it with particles prepared separately and then brought together.