Fusion energy has long been a goal for scientists and sustainable energy proponents alike. In recent years, several private firms have joined the effort. Here, Alex Creely and Erica Salazar describe how one such company, Commonwealth Fusion Systems, is betting on advanced magnet technologies to make the fusion dream a reality

Fusion, with its promise of unlimited, safe, carbon-free energy, has for many years occupied a special place in the imagination of physicists. The process of combining small atoms into larger ones releases enormous amounts of energy (fusion fuel is more than a million times more energy dense than fossil fuels), and the goal of harnessing this energy to generate electricity has been pursued by scientists in laboratories around the world since the 1960s.

So far, a practical fusion power plant has proven elusive. This is perhaps not surprising, given the difficulty of replicating conditions similar to those in the centre of a star. Before fusion can take place, the electrical repulsion of the atomic nuclei that make up the fusion fuel must be overcome, so that atoms get physically close enough to fuse. To do this, the fusion fuel must be heated to temperatures of around 200 million K. At these temperatures, all matter exists as a plasma, in which electrons and nuclei have separated to form what can be thought of as an ionized gas.

The task of creating and containing these plasmas raised technical hurdles that were sometimes underestimated. For example, the role of turbulence in transporting heat out of plasma confinement systems was once poorly understood. Now, however, these hurdles are being overcome. Building on past progress, and enabled by a new generation of superconducting materials, fusion scientists and engineers are pushing the technology still further, with the goal of realizing a fusion power plant soon enough to make a difference on climate change.

Apart from this technological progress, one of the most exciting recent developments in the field has been the rapid growth of private investment in fusion. There are now more than a dozen companies around the world working toward the goal of fusion energy, each focusing on slightly different strategies to get there. The ability of these companies to attract investment is both an indication of the value placed on achieving fusion energy and a validation of the ongoing research in labs worldwide.

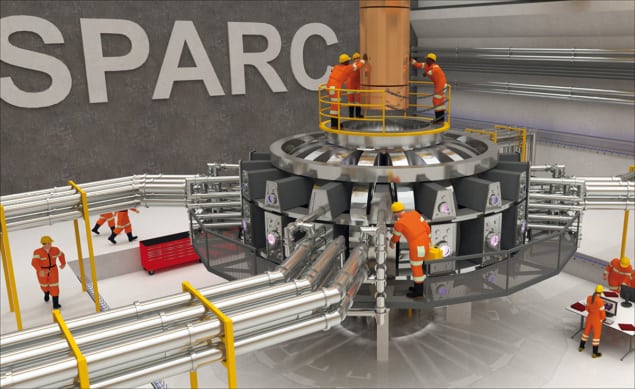

Commonwealth Fusion Systems (CFS) was founded in mid-2018 as a spin-off from the Massachusetts Institute of Technology’s Plasma Science and Fusion Center. Its scientists are now working closely with colleagues at MIT in order to design and construct SPARC, a new fusion device aiming to be the first to achieve net energy gain – that is, producing more energy than is required to heat the plasma and sustain the fusion reactions.

Smaller superconducting magnets

Multiple approaches to create and contain fusion plasmas have been pursued, but the most successful to date – and thus the one CFS has adopted – involves confining the hot fusion plasma in a device known as a tokamak. In this type of fusion device, strong magnetic fields produced by powerful electromagnets are used to contain the plasma in a toroidal (doughnut-shaped) vacuum environment, in order to insulate and isolate the plasma from ordinary materials. Radio frequency waves or one of a few other methods are then used to heat the plasma.

The highest-performing tokamak so far, in terms of the ratio of fusion power to the required heating power, is the Joint European Torus (JET) in the UK, which was constructed using copper magnets. A viable fusion power plant, however, will require superconducting magnets to ensure that the power expended in running the magnets is far less than the fusion power generated by the device itself.

In principle, magnets made from conventional low-temperature superconductors, such as Nb3Sn, can achieve this. However, these materials are severely limited by how much current can pass through them at high magnetic field, which in turn limits the strength of the magnetic field that they can produce. To overcome this and construct a tokamak that will produce a net energy gain, one must therefore make the machine very large, and thus very expensive. This limitation is what led to the design of the ITER tokamak, which is currently being constructed in France under the aegis of an international collaboration, to the tune of tens of billions of dollars. The enormous size of ITER and the complexity of organizing many international partners have put the project far behind schedule and over budget, with a current expected peak performance date somewhere around 2035.

What sets SPARC apart from ITER, JET, and other previous fusion tokamaks will be its use of a new type of high-temperature superconductor (HTS), yttrium barium copper oxide (YBCO). Current-carrying tapes made from YBCO remain superconducting at considerably higher magnetic fields than is possible with older superconductors. This is valuable because higher magnetic fields improve the thermal insulation of the plasma and thus allow for considerable improvement over the performance of previous tokamaks.

YBCO superconductors have existed for a number of years, but they have only recently become commercially available in the quantity and quality required for fusion devices. By using this new superconductor to develop high-field magnets – capable of producing fields of 12 T at the centre of the plasma, compared to 5 T in ITER – CFS and MIT hope to drastically accelerate the timetable to fusion energy and achieve net energy gain in a device that is roughly 2% the size of ITER. To make a comparison, we believe that YBCO superconductors will be an enabling technology for fusion in the same way that lightweight internal combustion engines were an enabling technology for powered flight.

The SPARC project’s first task, over the next few years, will be to build and test a full-scale prototype HTS fusion magnet

Material progress

Although high-temperature superconductors benefit the design of fusion power plants by reducing plant size, lowering capital costs, and allowing for higher operating temperatures, they also pose challenges and technical risks that must be overcome. These challenges include higher mechanical stresses in the magnets, larger heat loads from the fusion process, and the uncertainty of manufacturing and operating a first-of-its-kind HTS coil. To mitigate these technical risks and validate the magnet system design, the SPARC project’s first task, over the next few years, will be to build and test a full-scale prototype HTS fusion magnet.

The prototype HTS coil will demonstrate the operation of the magnet system and test the integrated cryogenic coolant system used to cool the superconductors to 20 K – the operating temperature required to generate the high magnetic fields in SPARC. Maintaining this temperature in SPARC will be challenging, since the compact nature of SPARC leads to higher power density and thus high heat fluxes generated by the fusion reactions in the core of the machine. Additionally, the properties of the mechanical structure around the conductor in the magnet depend strongly on the temperature of the materials, and therefore this structure must be kept cold in order to withstand the stresses generated in the magnet. The model HTS coil will therefore experimentally validate the heat removal capabilities in HTS magnet systems, and the lessons we learn from it will be critical in moving the SPARC project forward.

In addition to addressing structural and cooling challenges, one of the primary missions of the prototype HTS coil will be to investigate our ability to detect and mitigate a “quench” event, which is a sudden loss of superconductivity due to external events such as reaching critically high temperatures, current, or strain levels. A quench can lead to rapid, localized heating of the superconductor, potentially causing damage if the magnet is improperly designed or operated. Understanding how to detect and prevent quench events is of particular importance for the robustness and reliability of the magnet and fusion system.

Compared with older, low-temperature superconductors, HTS magnets are more stable in the face of local heating due to their higher operating temperature. For these same reasons, however, the quenched area of the magnet, which is no longer superconducting, can propagate more slowly in HTS magnets than in previous superconducting magnets and may be more likely to experience damage. Understanding how a quench event initiates and grows, and devising quench detection and mitigation techniques, is critical to the design of robust HTS magnets that are resilient to quench. Both of these systems will be proven on the prototype TF coil. After the successful completion of the prototype TF coil, MIT and CFS will go on to construct the SPARC device, and push toward practical fusion energy.

Considering the ambitions of the SPARC project, there is plenty of room for innovation and new ideas to address the various challenges in the development of fusion energy. CFS is looking for further improvement and innovation in the future with HTS joint technology, as well as with other technologies, such as power exhaust via advanced diverters and energy capture and conversion systems for next generation power plants like ARC. ARC plans to integrate the results of SPARC with these advanced technologies in order to be the first fusion power plant to demonstrate electricity generation. The passion for tackling technical challenges and developing innovative ideas to push these technological barriers is exactly what the fusion industry needs to reach our goal of limitless, clean energy.