Margaret Harris explores how miniature satellites called CubeSats are opening up the space industry to new customers and mission types

Scientists have big hopes for NASA’s Mars InSight mission. When this billion-dollar spacecraft reaches its destination on 26 November, after a six-month trip, a robotic lander will descend to the red planet’s surface. If the lander survives this hazardous final journey, it will spend the next two years studying the interior of our nearest planetary neighbour, burrowing into Mars’ crust with a self-propelled, mole-like hammer and attempting to detect quakes using a special seismometer placed directly onto the planet’s surface. For mission scientists at NASA’s Jet Propulsion Laboratory (JPL), the reward for all this effort and expense will be a wealth of information about the Martian crust, mantle and core.

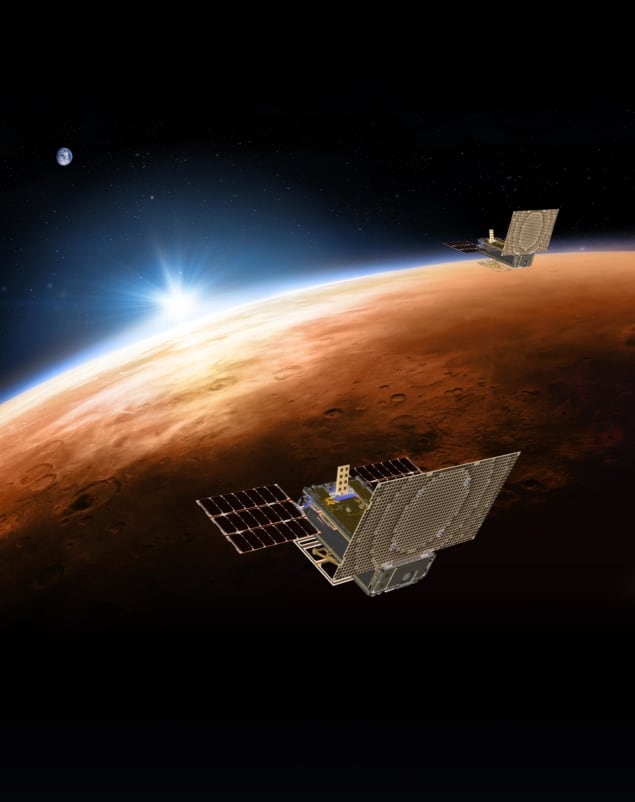

Even before the lander arrives, though, the Mars InSight mission has already made history – thanks to a pair of briefcase-sized objects that travelled into space atop the same Atlas V rocket. The twin Mars Cube One (MarCO) satellites cost a relatively modest $9m each, and with a combined mass of just 26 kg, they made up less than 4% of the mission’s total payload. Their goals are correspondingly limited: in NASA parlance, the MarCOs are a “technology demonstration”, meant to perform communication and navigation experiments and not to make scientific discoveries. Even so, these unassuming little boxes are pioneers. As the first in a class of miniature spacecraft known as CubeSats to travel beyond Earth orbit, the successful launch of the MarCOs marks the latest milestone in a trend that is sweeping the space industry — changing not only what spacecraft look like but also the types of missions they can perform, and who gets to perform them.

To understand why CubeSats are such a game-changer, consider the Mars InSight mission again, this time in a slightly different light. The lander at the mission’s heart is a highly capable object, but it is also a complete one-off. Most, if not all, of its components were designed specifically for the InSight mission, and before they got anywhere near the launch pad, they underwent a rigorous, lengthy and expensive testing process to reduce the risk of malfunctions. This degree of care and precision is crucial when dealing with instruments and systems that come with six- or seven-figure price tags, but it pushes up the total mission cost, too. The result is an amazing piece of equipment that is, alas, completely beyond the reach of all but a handful of organizations worldwide.

In contrast, CubeSats like the MarCOs have been built and flown by private companies, university research groups, countries without multibillion-dollar space programmes, and even high-school students. Naturally, these miniature satellites can’t do as much as a robotic Mars lander — but then, they don’t cost as much either. In fact, many are such bargains that, in the words of Patricia Beauchamp, a programme manager at the JPL, “you can send up three of them and lose two, and that’s just fine.” The twin MarCOs are a good example of this ethos. Although somewhat costly by CubeSat standards (thanks in part to the demanding environment of interplanetary space), they are still sufficiently small and inexpensive that there was room and budget to include two in the Mars InSight mission – just in case one of them didn’t work.

Off the shelf

The low cost of CubeSats is partly due to their size, but it’s also a question of shape and standardization. As the name implies, CubeSats pack all of their instruments into a box measuring 10cm on a side. Some CubeSat missions incorporate three, six or even 12 such boxes (the MarCOs, for example, are six-unit CubeSats), but regardless of how many units are involved, the standard size and set of connections for each module means that many components, such as radiofrequency antennae or electronic interfaces, can be purchased off the shelf. That reduces costs even further, to the point where satellite manufacturers are beginning to talk seriously about economies of scale – a concept that has long been alien in an industry dominated by highly specialized, custom-built systems. “We are not handcrafting satellites so much anymore,” says Rafael Jordá Siquier, founder and CEO of Open Cosmos, a UK-based start-up that specializes in building CubeSats and other small satellites. “We are following a mass production process where we make and provide the services for many satellites at the same time.”

Truly mass-manufactured satellites are some way off, and Jordá Siquier cautions that in the space industry “many satellites” might still mean 10 or fewer. However, CubeSats and similarly-sized craft (known generically as smallsats) are already helping to break what had been a vicious circle, where the inherent riskiness of the space business tended to push up already high technology costs, putting off new entrants. “We’re living in a time when I believe there is a big space revolution, and it’s empowered by this technology,” Jordá Siquier says. “I compare it to what happened in the 1980s, when computers stopped being big and expensive and available to a few key players and became small and affordable enough that more people could start using them.”

Small size, big impact

Jordá Siquier also likes to draw parallels between the capabilities of smallsats and those of early microcomputers. “Ten or 15 years ago, people thought that nothing useful could be done with this sort of technology,” he explains. “They didn’t know what they would be using them for. However, as time has gone by and companies like ours have been able to provide technology and services that are more customer-oriented and simple to use, we are starting to see applications emerging in a broad range of domains.”

As examples, Jordá Siquier cites several applications related to Earth observation, including the remote monitoring of crops, major pieces of infrastructure and shipping. The telecommunications industry, too, stands to benefit from the CubeSat revolution: dedicated smallsats could act as relay stations to facilitate satellite-to-satellite communications, while constellations of dozens or even hundreds of CubeSats could bring fast Internet connections to remote areas. On the scientific side, Beauchamp says that groups of smallsats could facilitate new types of missions, such as sending multiple small spacecraft to rendezvous with a single planetary body. “Those are very attractive concepts for getting data that you currently can’t get, or getting it at much lower cost,” she says. “You might have 10 satellites with the same instruments, or you could have all of them have slightly different instruments. There’s lots of games you can play to look at the risks and evaluate what you can do.”

[With CubeSats] you can send up three of them and lose two, and that’s just fine

Patricia Beauchamp, NASA-JPL

Fixing a bottleneck

With so many potential applications for smallsats, and decreasing amounts of money and know-how required to build them, it is hardly surprising that launch providers are struggling to meet demand. Most CubeSat and smallsat missions travel into space on a “rideshare” basis, tucked in alongside bigger, more expensive satellites like stowaways in the hold of a cargo ship. This makes it possible to launch several CubeSats on the same rocket, and helps keep overall costs down, but Jordá Siquier observes that it also restricts customers to whichever orbits the prime contractor wants to reach. In practice, these are often the most crowded geostationary or Sun-synchronous orbits, which may not be suited to the smallsat mission’s needs. Their popularity also means that launch windows are limited, raising the likelihood of weather-related delays.

Sharing a ride restricts the types of payloads that smallsats can carry as well. Natalya Bailey is the CEO and co-founder of Accion Systems, a Boston, US-based start-up that builds ion engines for small spacecraft. She explains that commercially-launched smallsats usually have no onboard propulsion systems because of the attendant hazards. “It’s quite dangerous to put a large pressurized canister of a gas on board,” she explains. “If you were trying to launch your spacecraft as a secondary payload, the primary payload might not accept it. Some of these primary spacecraft are worth one to two billion dollars. They don’t typically want to risk that.”

Limits on payload type and launch slots help to explain why a January 2018 test launch by a small and relatively little-known start-up, Rocket Lab, drew so much attention in the smallsat community. The second-ever launch of the company’s Electron rocket was code-named “Still testing”, but it nevertheless succeeded in placing three customer payloads in orbit: two CubeSats from Spire, a US-based weather data firm, and one from an Earth-imagery specialist, Planet.

Rocket Lab’s first real commercial launch was due to take place on 22 June at its dedicated launch facility in New Zealand’s Mahia peninsula, but was postponed because of a problem with a tracking dish. A company spokesman told members of the press that they hope to try again later in the week. However, even if weather or technical problems produce further delays, the US-headquartered firm appears well-placed to capitalize on the burgeoning launch market for smallsats. According to mission management and integration director Daniel Gillies, Rocket Lab aims to provide affordable, frequent launch services designed specifically for smallsat customers. “You want to go to a 650 km Sun-synchronous orbit with a launch date and time that no-one else wants? No problem,” Gillies told Physics World a day before the scheduled launch. “You can buy the entire vehicle, or at least charter a large proportion of it, and effectively it’s like chartering the private jet. You’re getting to go exactly to the place you want to go, when you want to arrive there.”

With a payload capacity of just 150 kg, Rocket Lab’s Electron is a minnow compared to older launch vehicles like the United Launch Alliance’s Atlas V or SpaceX’s Falcon 9. However, it can carry up to 24 CubeSat-type payloads into low-Earth orbit on a single launch, and it is also relatively quick to construct: Gillies says that 3D printing technology allows them to build up to one engine every day. By the end of 2018, the company hopes to be launching an Electron every month, either from its Mahia facility or from a second launch site at a still-to-be-determined location.

Satellites on the move

Some of the longer-term possibilities for smallsat technology would require all of this launch capacity and then some. Bailey, of Accion Systems, is confident that better, safer propulsion systems (such as the one she and her colleagues have developed, which uses an ionic liquid as a propellant) will significantly extend what smallsat makers can do, and where their craft can go. As an example, she describes a hypothetical customer who wants to launch many satellites at once, then spread them out along a particular orbit — perhaps to conduct ground observations over a large area or set up a telecommunications network. Satellite constellations of this type cannot be constructed without onboard propulsion or separate multi-stage launches, and even the enthusiastic Gillies says that Rocket Lab hopes to replenish mega-constellations of 1000+ satellites, not launch them in the first place.

Onboard propulsion also gives satellites a longer lifespan, enabling them to nudge themselves back into a higher orbit or take evasive action if they end up on a collision course with a piece of space debris. Such collisions are real possibility: Bailey explains that she was once in the control room of another space start-up when they received an alert from NASA about a potential collision risk to their prized satellite. “They had no propulsion, so the whole room was just silent, holding their breath, hoping that it didn’t happen,” she recalls.

Of course, CubeSats aren’t just at risk of being hit by space debris. They’re also at risk of becoming debris themselves, and the potential environmental implications of launching large numbers of small, expendable satellites into Earth orbit are not lost on the smallsat community. “Space debris is one of the key things that people developing this industry have to be very, very aware of – and very responsible for,” Jordá Siquier says. “We have to be careful of not polluting the environment where we develop our business.” Beauchamp, however, is less concerned. “Things are beginning to get a little crowded in various spots, but I think it’s going to be a while before it’s a problem,” she says. The reason, she explains, is that most smallsats are launched into low-Earth orbits, and without onboard propulsion, their orbits will decay – ensuring that they self-destruct by burning up in the Earth’s atmosphere within a few years.

It is also possible that CubeSats, far from adding to the collection of space junk, could help to reduce it. In 2017, an Italian start-up called D-Orbit test-flew a CubeSat designed to direct itself (and, in future, any other craft it attaches to) into a doomed orbit on command. As missions go, it may not be as glamorous as relaying messages from a Martian lander, but if CubeSat technology is to achieve its full potential, an army of little clean-up craft might be just what the industry needs.