Gouda news for cheese makers! A systematic way of using sound waves to non-destructively probe the ripeness of emmental-style cheeses has been developed by researchers in Uruguay. The approach, which can reveal when holes in the cheese first form — and when they are becoming too large — could make precise quality control quick and easy to implement on an industrial scale.

Cheesemaking is a complex process, involving many steps that must be precisely executed to ensure the quality of the ultimate product. For semi-hard cheeses like emmental, gouda and maasdam, the final stage is a lengthy period of ripening, during which the cheese develops its various and characteristic sensory properties — such as aroma, colour, flavour and texture. Also created at this stage are “eyes”, which are holes within the cheese formed by the bacterial release of carbon dioxide.

Allowing insufficient time to ripen leads to a poor-quality, low-value cheese. On the other hand, excessive ripening can allow the eyes to merge, an outcome that can lead to the cheese collapsing in on itself. At this point, the cheese can no longer be sold as intended and must be repurposed, for example as a grated cheese or an ingredient in other foods. In fact, the international food standards publication the Codex Alimentarius calls for regularly-shaped eyes between 1–5 cm in diameter in cheeses.

To ensure the desired ripening, cheesemakers use various techniques to monitor ripeness and eye formation. Cheeses can be cut and their eyes visually inspected, or samples of the cheese can be subjected to humidity analysis or textural measurements, which determine key properties like hardness, viscosity and chewiness. The drawback of these approaches, however, is that they require a wheel of cheese to be sacrificed for samples each time the tests are run – cutting into potential profits.

Cheese hammer

Some cheesemakers, however, have a non-destructive alternative; they tap the cheese with a special hammer and, from the sound, can determine whether the cheese is ripe enough. An expert can also tell whether the cheese contains defects like slits or “gas blowings” that can cause the wheel to swell. This technique, however, is very difficult to master and requires cheesemakers of considerable experience.

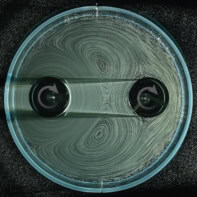

Now, engineers Mariana González and colleagues of the University of the Republic in Montevideo have characterized the tap test so that it could be automatically and reliably performed by machines. The team took eight 8 kg wheels of an emmental-type cheese that had already undergone pre-ripening and ripened them in a temperature and humidity -controlled chamber at around 18 °C and 75% relative humidity, turning each twice weekly.

During this process, the cheeses were acoustically probed daily using an electric hitting device – and every five days the researchers cut open one wheel to observe the extent of eye formation and perform texture and humidity analyses.

Signal cross-correlation

The team explored their acoustic data using two digital signal processing techniques: first order momentum (FOM) and signal cross-correlation.

“FOM of an acoustic signal is related to the tone of the sound and ‘summarizes’ all changes in the spectrum of the acoustic signal by averaging the distribution of the frequencies of the sound,” González explains. She adds: “On the other hand, cross-correlation is a function that indicates how similar two signals are.” In this case, the signals compared were those taken during ripening and a baseline signal from the first day of the study.

The researchers found that at low frequencies of 0–50 Hz, FOM was sensitive to the beginning of eye formation at around 10 days of ripening. Meanwhile, medium frequency (50–500 Hz) FOM and cross-correlation both gave indicators when the eyes began to overgrow, which occurred after around 20–25 days. Both transitions are the result of the changing attenuation of the sound waves through the cheese. This is a result of both alterations to the cheese’s structure and scattering from eyes. Neither texture nor humidity analysis could indicate when eyes began to form.

“Fast and easy to implement”

González describes the technique as “fast and easy to implement,” although she cautions that the acoustic indicators are unique for each type of cheese and processing conditions. “For each type of cheese and manufacturer, a calibration will be required.”

Land of milk and neutrons

With their initial study complete, the team is now looking to collaborate with local cheese makers to test how the acoustic monitoring method would integrate with a real-world production site.

“Having an inexpensive and simple method to monitor eye formation could improve the quality of the products, especially in small and medium producers,” she says.

The research is described in Innovative Food Science and Emerging Technologies.