A Danish effort to bring neutron and X-ray scattering expertise to companies has reaped benefits for the dairy industry, and participants aren’t letting the grass grow under their feet. Erik Brok and Søren Roi Midtgaard outline plans to milk the partnership further

If you go on a scenic drive through the Danish countryside, you will see a lot of cows. That is not surprising: Denmark has around half a million dairy cows, spread over less than 43 000 km2 of land. What is, perhaps, surprising is that there is a link between these placid, productive creatures and a multibillion-euro research infrastructure for neutron and X-ray scattering. The connection exists thanks to researchers at the University of Copenhagen, who spotted an opportunity to use advanced research facilities to investigate the complex hierarchical structure of milk and milk-derived products.

The dairy studies date back to 2013, when the university, with support from the capital region of Denmark, began a pilot project to test the feasibility of employing X-ray and neutron scattering in industrial R&D settings. This project, known as NXUS (Neutron and X-ray User Support), established collaborations between industry and university scientists on many different topics, including the processes that take place when paint dries and techniques for enhancing the stability of protein-based drugs. However, dairy companies and their specific challenges were a major focus of the project, with companies such as Arla Food Ingredients, CO-RO A/S and DuPont Nutrition Biosciences ApS all interested in questions related to the processing and handling of milk products.

Dairy details

Milk is a complicated system with many constituent elements. However, some of its most important properties can be understood by considering it as a colloid of casein, or milk protein, arranged in globular agglomerates of thousands of individual casein molecules. These agglomerates are known as micelles, and their overall size is in the micron range. Closer examination, though, reveals that the substructure of these micelles is highly hierarchical, with features of various sizes. Examples include clusters of calcium phosphate that are only a few nanometres in size; groups of individual proteins that are some 15–20 nm across; and the overall structure of the micelle (hundreds of nanometres) and its surface. These substructures are very important for the properties of the milk, and in particular for the texture and “mouthfeel” of the finished product, whether it is yoghurt, cheese or anything else derived from milk.

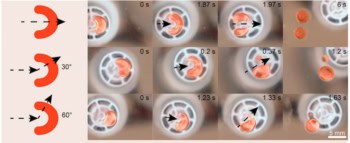

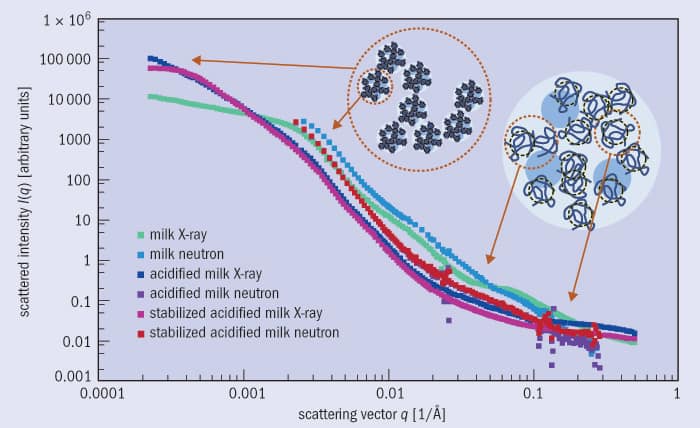

Small-angle neutron and X-ray scattering make it possible to study features with length scales from 1–1000 nm (see “Small-angle scattering” figure below), so they are perfect tools for studying casein micelles. One such study, performed in collaboration with DuPont Nutrition Biosciences, used a combination of SAXS and SANS to examine ways of stabilizing acidified milk in solution. Acidification of milk can lead to aggregation (or coagulation) of the casein micelles, and one needs to control this process in order to produce the desired dairy product – for example a certain type of cheese or yogurt – with the desired texture and stability. In this study, the structure of the casein micelles was studied before and after acidifying the milk, and before and after adding a stabilizing agent to the acidified milk. On a macroscopic level the samples differ in texture and the SAXS and SANS data reveal that at the nanoscale, too, there are clearly identifiable differences (see “Milking the data” figure below). The data also illustrates the benefit of using both X-rays and neutrons, since some features are only visible in one of the two corresponding data sets.

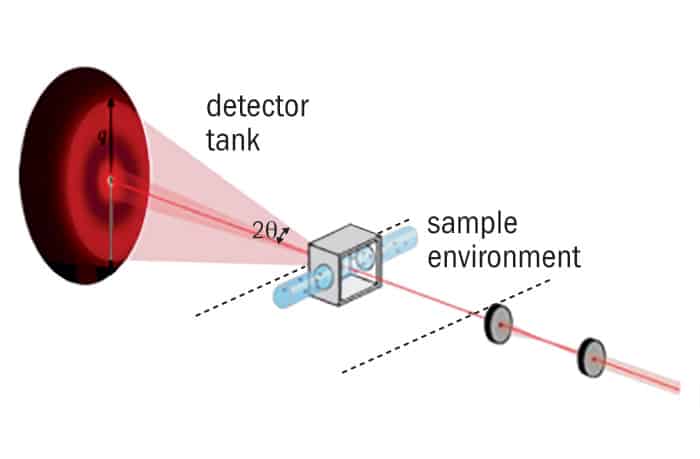

Small-angle scattering

In small-angle scattering (SAS), a sample is placed in an X-ray or neutron beam (SAXS or SANS, respectively). Typical samples are protein solutions, emulsions or solutions of nanoparticles, detergents or polymers. The sample scatters the beam and the scattered intensity is measured as a function of the scattering angle, typically up to 5°. The detected scattering pattern is related to the Fourier transform of the sample structure, and thus makes it possible to determine the size and shape of scattering particles within the sample on length scales of between 1 and 100 nm (and sometimes even up to mm, depending on the experimental set-up).

While SAXS is widely available at small-scale lab facilities, SANS is more difficult to come by because it requires a neutron source in the form of a nuclear reactor or a spallation source. Nevertheless, SANS can offer great advantages over SAXS; in particular, the former technique can easily “see” the light elements that are so important for life. These light elements (hydrogen in particular) are either hard or impossible to see with SAXS and other X-ray based techniques, which are more sensitive to heavy elements. SAXS and SANS are often used in combination because they have a different scattering contrast with respect to the sample. Thus, employing both of these complementary techniques often makes it possible to learn about structural details that would not be possible to determine with either technique on its own.

Armed with some prior knowledge of the constituents of casein micelles, it is fairly easy to deduce, from visual inspection of the data, what is going on. The disappearance, after treatment, of the feature visible around a scattering vector q = 0.08 Å–1 in the scattering curves of the untreated milk samples indicates that calcium phosphate clusters in the micelles disappear upon acidification. Furthermore, the general suppression of features in the middle range of the data, around q = 0.01 Å–1, indicates a collapse of the micelle’s internal structure. Finally, acidification seems to make micelles cluster together in larger aggregates, but this clustering is reduced when the stabilizer is added. This can be deduced from the increase in scattering in the very low-q range of the data (the far left in the figure) on acidification, followed by a slight decrease and flattening when the stabilizer is added. A more detailed analysis of these data enabled DuPont Nutrition Biosciences to better understand the effects of their natural stabilizers on micelle mechanics at a molecular level. Projects involving Arla Food Ingredients and CO-RO A/S similarly provided the companies with specific knowledge that they would not otherwise have gained.

Assessing impact

With Denmark’s national milk production nearing 5 billion kg per year, and dairy exports worth €1.8bn to the economy annually, even a slight industry edge could have a large impact – not only for the individual dairy companies, but also for the country as a whole. But the effect is not necessarily limited to Denmark’s current industries. Richard B Larsen, a senior advisor at the Confederation of Danish Industry (CDI), argues that with the European Spallation Source (ESS) being built less than an hour’s drive from Copenhagen, and the neighbouring MAX-IV synchrotron facility already operating, international companies may choose to base their R&D departments in Denmark “due to the easy access and accompanying knowhow in applying neutrons and X-rays to investigate problems of industrial relevance.” With time, he adds, the expectation is that a robust industry research sector will generate highly specialized jobs that will, in turn, help realize the full potential of the area’s world-class research infrastructure.

structural difference between raw milk, acidified milk and acidified milk with an added natural stabilizer. These differences occur at various length scales and correspond to changes in the sub-structures of casein micelles in milk. SAXS data comes from the ID-02 beamline at the European Synchrotron Radiation Facility (ESRF) in Grenoble, France and SANS data from the KWS-2 instrument at the Forschungsreaktor München-II in Germany.

Larsen’s enthusiasm is mirrored by Lise Arleth, a professor at the Niels Bohr Institute at the University of Copenhagen and founder of the NXUS project. The institute has a long tradition of exploiting neutrons and X-rays for basic science, she explains, so “having the NXUS project embedded in my research group has been a great opportunity to get experience in actually performing these industrial R&D projects on a larger scale.” Getting a new generation of scientists involved in industrial challenges has also been rewarding, Arleth says, since “they are the ones that ultimately will have to meet all the future expectations in this area.”

Those future expectations have already led to a new, larger partnership being founded with the aim of putting neutron and synchrotron science to work on industrial problems. The new LINX (Linking Industry to Neutrons and X-rays) consortium comprises three Danish universities and 15 industrial partners, with additional support from Innovation Fund Denmark, the CDI and two Danish regional governments. These organizations have committed to finding solutions to larger and more challenging questions relating to materials in general, including the food and biomedicine sectors. The LINX project is funded for five years, and a parallel LINX Association has also been established to give the project a sustainable long-term future as a platform and mediator for industrial use of neutron and X-ray methods after the public funding runs out.

Such long-term thinking is critical, in Arleth’s view. “Right now, we have many Danish companies that are highly interested in the opportunities provided by the upcoming ESS and MAX-IV, but they are just not sure how exactly they will benefit from the opportunities provided,” she says. “Presently, only a handful of Danish companies independently conduct experiments at the current large-scale facilities. The LINX project gives us an excellent opportunity to provide qualified answers to many of the ‘how’ and ‘what’ questions the companies have.” By the time the initial five years of funding runs out, she says, they hope to be able to demonstrate a significant increase in the number of Danish companies seeing benefits from applying neutron and X-ray technology to improve their products – plus several examples to inspire others to follow the dairy firms’ lead.