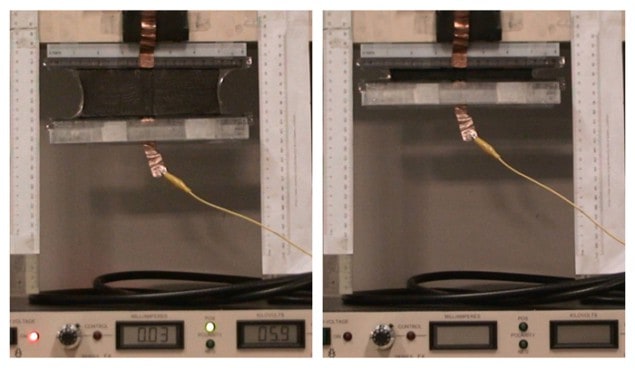

Human-like artificial muscles that can extend to five times their original length while lifting loads 80 times their own weight have been developed by researchers in Singapore. Made from polymers, the artificial muscles mimic the operation of their natural counterparts by contracting and expanding rapidly in response to electrical stimuli. This development is a first for robotics and could pave the way towards a new generation of more efficient, greener and cheaper robots.

The core of the breakthrough comes in the use of dielectric elastomers to form the muscles. In theory, such materials can stretch over 10 times their original length without breaking – enabling them to undertake a range of operations while still carrying heavy loads of many times their own weight. This is unlike today’s artificial muscles that are based on hydraulic designs and only capable of lifting loads up to half of their own weight.

“Our materials mimic human muscle, responding quickly to electrical impulses, instead of slowly [like] mechanisms driven by hydraulics,” says lead researcher Adrian Koh, of the National University of Singapore, adding that robots with their artificial muscles would move smoothly, unlike their hydraulic counterparts. “Robots equipped with such muscles will be able to function in a more human-like manner – and outperform humans in strength.”

Energy harvesting

The muscles also have another important potential application, according to the team. While originally designed to convert electrical energy into mechanical energy, they can also work the other way by generating and storing energy harvested from mechanical movements. According to Koh, a 10-kg muscle-based “soft generator” would be capable of generating electrical energy at the same rate as a one-tonne electrical turbine. In terms of storage, the artificial muscle acts much like a capacitor that is able to reach full capacity very quickly, offering rapid charge times.

As the polymer material is comparatively inexpensive, robots made with these artificial muscles should be much cheaper than those using existing alternatives. Indeed, Koh says that an artificial muscle would cost about 5% of the price of a comparable hydraulic system. The muscles also have the potential to use much less energy than hydraulic systems. As a result, Koh believes that muscle-based robots could become popular consumer products, much like tablets and smartphones are today.

The artificial muscles could have many other potential applications beyond just robotics. For example, Koh says that the technology could be used to create a new generation of more efficient cranes.

Fully soft machines

Commenting on the research, Robert Shepherd at Cornell University says “[This] work on electrically addressable artificial muscles is a big step forward to creating fully soft machines that can operate quickly and with enough strength to perform useful tasks.”

Looking to the future, the researchers are continuing to improve their robotic muscles: their next goal is to develop a muscle that can operate repeatedly over a million cycles. In three to five years, the team expects to be able to integrate the muscles into a fully functional robotic arm that is capable of performing such tasks as picking up and accurately repositioning loads. The arm will even be able to take part in an arm-wrestling contest with a human being, Koh says, adding: “We, of course, hope our arm will win!”