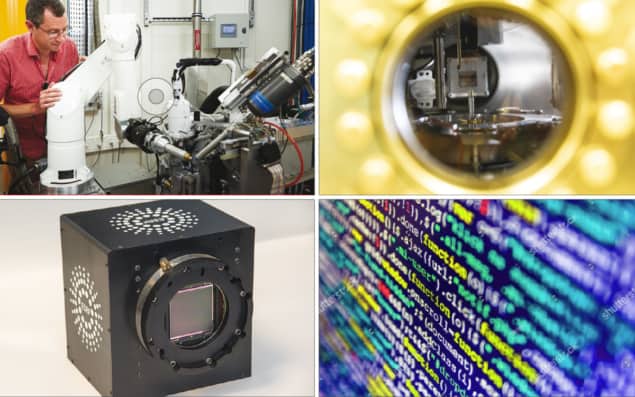

A major upgrade to make the ESRF light source even brighter will rest on four pillars of instrumentation, as Jon Cartwright reports

Synchrotrons push the boundaries of science at every frontier. On the one hand, synchrotrons such as the Large Hadron Collider at CERN in Geneva – accelerators designed to smash particles together at high energies – test the very foundations on which physics is based. On the other hand, synchrotrons can also be used to explore the less grandiose, but just as important “science of the everyday”. No particle-smashing takes place at synchrotron facilities; instead the goal is to harness the light – typically X-rays – generated when charged particles are accelerated continuously in a ring. These X-rays can be focused on pretty much any material – biological tissue, protein crystals, cosmetics, engineering alloys, superconductors and dinosaur fossils to name just a few – in order to determine how they behave, and understand why.

Initiated back in 1988, the European Synchrotron Radiation Facility (ESRF) in Grenoble, France, was the first “third generation” synchrotron. This meant that the charged particles it accelerated, electrons, were forced to wiggle inside special magnets to generate X-rays of extremely high brilliance. Over the years, the facility has been integral to several momentous discoveries, such as the structure of the ribosome – the subject of the 2009 Nobel Prize for Chemistry. But now, 30 years and 30 000 publications into its life, the ESRF is on the verge of a massive upgrade. The Extremely Brilliant Source (EBS) – as its new electron storage-ring will be known when it launches in 2020 – will multiply the brightness and coherence of X-rays by 100, illuminating the science of the everyday with unprecedented clarity. Though not the very first fourth-generation synchrotron, it will be the first operating at such a high energy – which is why four key areas of instrumentation must also be up to scratch.

Optics in focus

It probably comes as no surprise that incredibly bright and coherent X-rays demand incredibly high-quality optics. Optics transform a raw X-ray beam into a form best suited for a particular experiment, by tuning characteristics such as shape, energy, divergence and polarization. At a major facility such as the ESRF–EBS, the electron storage ring is surrounded by dozens of beamlines through which the X-rays are emitted at tangents, and every beamline is geared towards a specific type of experiment. Get its optics wrong, and a beamline could lack precision and stability, and its characteristics could even degrade over time.

That is why the ESRF–EBS project has a special development programme to address optics. The essential goal is to minimize the spatial and temporal perturbation of X-ray wave-fronts, and transfer X-ray flux to the samples at a beamline as efficiently as possible. Getting it right involves computer modelling, high-precision engineering, the development of new fabrication techniques, and testing outside and inside beamlines. The types of optics under scrutiny are crystal analysers (which measure the energy of X-rays in spectroscopy), multilayers (which focus X-rays, or select X-rays of a certain energy range), refractive lenses, mirrors, and measurement devices.

The ESRF has a strong pedigree in optics. Only last year, its ID16A beamline set a record for the highest resolution obtainable with high-energy X-rays – less than 13 nm – thanks to the installation of a new multilayer mirror. Besides nano-focusing, techniques such as imaging and coherent scattering (a special type of imaging in which the X-rays do not transfer energy to a sample) rely strongly on the quality of beam manipulation. But the impact of the optics programme will be far-reaching, giving a lift to the ESRF–EBS’s entire beamline portfolio.

Data collection

Few aspects of instrumentation capture the attention of users so much as detectors. Changes to detectors can alter the amount of data generated in an experiment by orders of magnitude. The ESRF is always improving its detectors, and in the next year or two several ongoing projects will come to fruition. One of these is the next-generation Frelon camera – a fast-readout detector used on a quarter of all ESRF beamlines, and at many other synchrotrons the world over. For the EBS, however, a dedicated detector development plan (DDP) aims to go further. Aside from developing advanced new detector systems, the DDP involves collaborating with external laboratories to access other detectors already in development, as well as improving related technologies – such as scintillators, which convert X-rays to visible light – that will help maintain the quality and productivity of ESRF–EBS beamlines.

The impact of the optics programme will be far-reaching, giving a lift to the ESRF–EBS’s entire beamline portfolio

The detectors themselves are being developed along two lines. The first, SMARTPIX, will be a photon-counting pixel detector with a 55 μm distance between pixels, based on the MEDIPIX3RX readout circuit developed by the international Medipix3 Collaboration, of which the ESRF’s Detector and Electronics Group is a partner. SMARTPIX will be faster and more flexible than previous versions, and it will also have the potential for greater temporal resolution. The second line of development is a series of large-format detectors for high-energy X-ray diffraction. These include fast detectors able to simultaneously detect both very intense and very weak X-ray signals, and detectors whose output current is proportional to the incident X-rays.

That’s not all. To supplement detector development, the ESRF is advancing three strategic technologies: X-ray sensors, which convert X-ray photons into a measurable signal; control and data-acquisition, which manages the throughput of data; and energy-dispersive detection technology, which involves the use of silicon drift diodes and germanium detectors to record the number and energy of X-rays emitted from a sample.

Robotic controls

With the launch of the EBS, many of the ESRF’s users will see data-acquisition times drop from milliseconds down to microseconds, and lower. That poses an issue for control systems, which will need to be more responsive to keep up, while maintaining synchronization with the EBS storage ring.

It isn’t purely about timing, however. As more and more experimenters look towards the nanoscale, and want to perform their experiments more efficiently, control systems also need to become both more precise and more automated. This is where robots – mechatronics – can help. The ESRF already has plenty of expertise here, for example with the almost fully automated MASSIF beamlines at ID30, which can be set up to collect millions of diffraction images of protein crystals every month, with practically zero human intervention – a truly massive time saver for drug discovery. For the EBS, a mechatronics task force has been created to work between groups within the ESRF’s Instrumentation Services and Development Division, and to provide a platform to share expertise in modelling, mechanics, electronics and software. A mechatronics laboratory is also forthcoming.

Various areas will see the benefits. Currently in development, a new double-crystal monochromator – the optical component that filters bundles of X-rays down to a single wavelength – will incorporate mechatronic concepts to improve precision and repeatability. Similarly, the Nano-positioning and Active Stabilization Stage, or NASS, project – part of a collaboration with engineering physicist Christophe Collette at the University of Brussels in Belgium and colleagues – is working on a prototype for a new generation of highly integrated end-stations in which sensors, measurement systems and mechatronics are all tightly integrated.

Managing data deluges

Faster experiments at higher resolution can only mean one thing: more data. So much data, in fact, that making sense of it will be a challenge in itself. To adapt their measurement strategies in real-time, users will need new, sophisticated ways of visualizing data. They will also need new ways of processing it on-site or online, as many of them will lack the appropriate computing facilities at their home institutions.

Fortunately, solutions are in the pipeline. The foundations for a new beamline control system, BLISS (which stands for BeamLine Instrumentation Support Software), have been laid, and it is already being deployed on the ESRF beamlines ID15 and ID31, as well as those of the Structural Biology Group. Meanwhile, software engineers have been busily developing SILX, a library of common data-analysis routines, generic applications and software. Now in its sixth release, SILX is being used in an increasing number of areas, and has been demonstrated to cut data-analysis times dramatically.

Myriad other changes behind the scenes will help funnel the data deluge. For example, a new ESRF data policy requiring metadata to be systematically recorded is being implemented; it is present on 11 beamlines already and will become the standard on a further 10 beamlines every year, until they are all covered. In the future, the policy could extend to acquiring and storing data in the flexible “HDF5” format, and standardizing its management, archiving and publication.