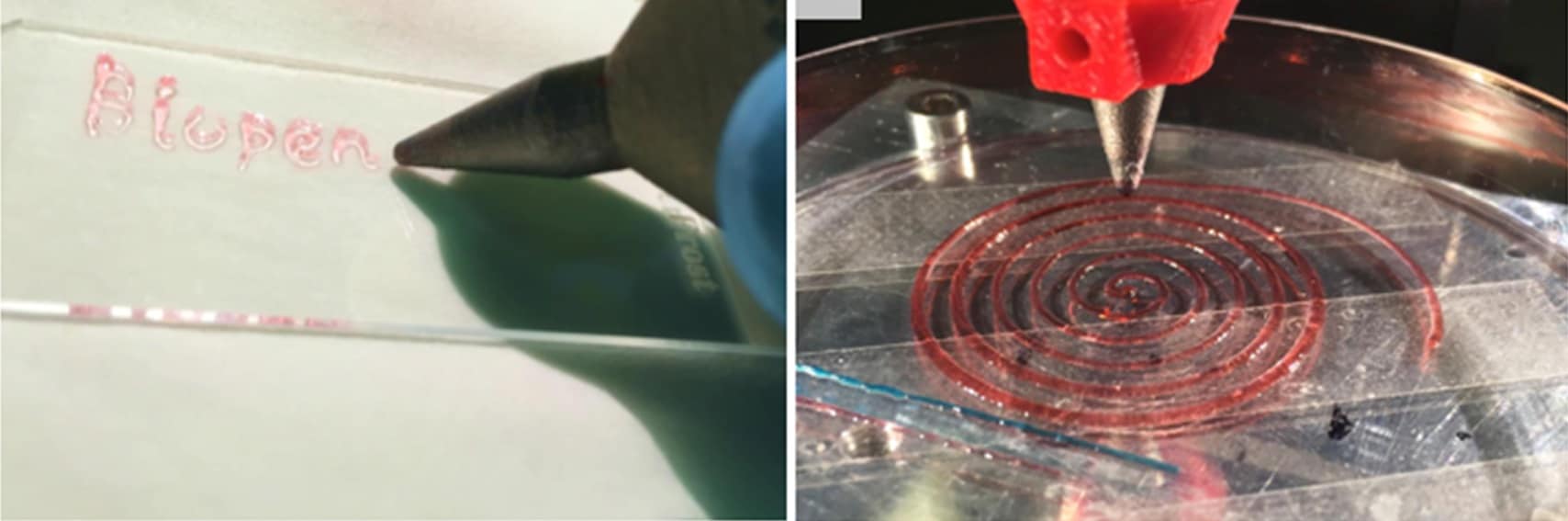

As 3D printing technology evolves and advances, we are getting ever closer to the goal of being able to implant 3D printed tissues inside the body. At present, 3D printed cells must first be cultivated and then allowed to grow into viable tissue – which normally takes a few days. But a new instrument, dubbed the biopen, could help to speed up this process. The biopen, developed by researchers in Australia, could allow surgeons to repair damaged bone and cartilage by “drawing” new cells directly onto bone during surgery and then filling in any damaged areas.

The researchers, led by Gordon Wallace of the University of Wollongong in close collaboration with Peter Choong, an orthopaedic surgeon at St Vincent’s Hospital in Melbourne, first reported their technique in the journal Biofabrication in 2016, and have now tested it out in experiments with sheep.

“The data obtained to date is highly promising,” says Wallace. “We are continuing to optimize printing protocols to demonstrate the versatility of the biopen.” The team is also now working with a manufacturer to produce a commercial device.

The prototype pen described in Biofabrication is made of medical grade ABS-like material and titanium 6Al4V alloy. It works by extruding a bioink, composed of stem cells inside a biopolymer, onto the surface of bone or cartilage. The ink is then solidified by photocuring it with light from an ultraviolet source fitted to the side of the pen. The device draws the stem-cell-containing structures directly onto a defect, and these structures subsequently differentiate into cartilage.

Specific clinical applications

In their paper, Wallace and colleagues report on using biopolymers such as those based on alginate, a seaweed extract, which was in turn protected by a hydrogel. Since then, they have been trying to identify other naturally occurring sources of biopolymers that may be suitable for bioinks, subject to some chemical modification.

“The biopen was our first foray into customized printing approaches for specific clinical applications,” Wallace told Physics World. “We now have an advanced programme for developing specially-designed printers and bioink formulations for use in a number of areas.”

“One of these is treating eye damage in the iFixpen project, which is a collaborative venture with the Sydney Eye Hospital,” Wallace continues. “Another is fabricating 3D-printed structures containing human islet cells for transplantation, which we are working on in association with the Royal Adelaide Hospital.”

A third project – which aims to create 3D printed ears for children with part of an ear missing – has also brought some interesting challenges, he adds. In this case multimaterial and stem-cell-containing structures must be printed in the appropriate shape, which has required the researchers to develop multiple ink formulations and a multihead printing system that will be provided by the Royal Price Alfred Hospital in Sydney.

“We also have a new fundamental research programme looking at printing and developing stem cells, such as induced pluripotent stem cells, and how they develop into neurons,” reveals Wallace. “This work will help us to obtain new insights into neural diseases.”

- This article is one of a series of reports reviewing progress on high-impact research originally published in the IOP Publishing journal Biofabrication.