Most biofabrication techniques make use of bioinks – hydrogel structures laden with cells and extracellular matrix components – that are extruded layer-by-layer to engineer functional biological tissues. But researchers are also developing cell-laden bioresins for lithography-based bioprinting technologies, such as stereolithography (SLA) or digital-light processing (DLP). These techniques could offer an attractive alternative, since they can create more intricate printed patterns that better mimic the complex tissue architecture.

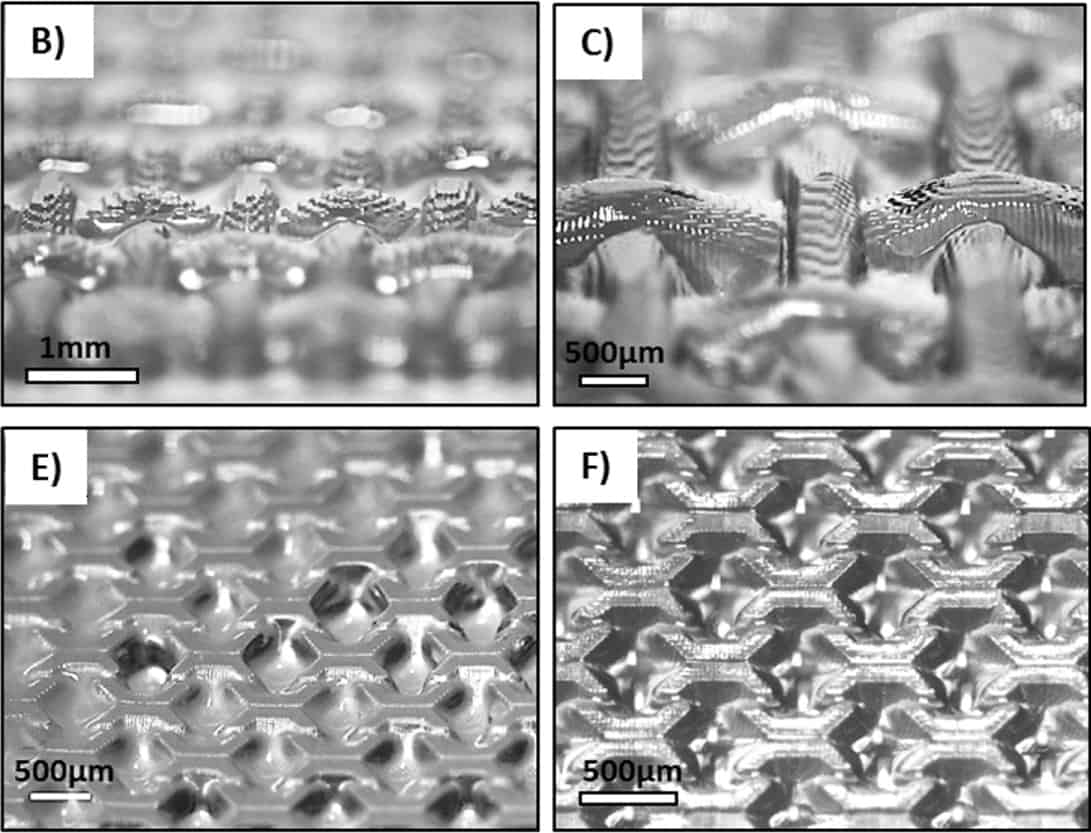

A team led by Tim Woodfield at the University of Otago Christchurch in New Zealand and collaborators at University Medical Center Utrecht in the Netherlands has now developed a new bioresin that allows them to use DLP to bioprint sophisticated cell-laden hydrogel structures with high-resolution features ranging in size from 25 to 50 microns. “Such structures cannot be fabricated using extrusion bioprinting,” says Woodfield.

The resin is made from two different types of hydrogel (PVA-MA and Gel-MA) and a photoreactive compound that initiates a chemical reaction when illuminated with visible light. When the resin is biofunctionalized with 1 wt% Gel-MA, more than 90% of the bioprinted cells survive for up to three weeks. The seeded cells also attach to the gel and successfully spread across it.

Bioresin opens up lithography

The DLP fabrication technique exploited by the team uses a digital micro-mirror device to project a patterned mask of light (usually in the UV or visible wavelength range) onto the bottom surface of a polymer resin bath. Specific regions of the resin are polymerized when exposed to light, and the platform then moves upwards as resin flows to produce a fresh layer before the process it repeated.

“Lithography-based fabrication technologies have long been used in jewellery making and in the automotive industry, for example, using a range of commercially-available resins,” explains study lead author Khoon Lim. “These resins often contain organic solvents or toxic chemicals and require photo-initiators that are only soluble in toxic organic solvents. To make our resins ‘bio’, we employed a combination of macromers (photo-responsive PVA-MA and Gel-MA) and the photo-initiator ruthenium. All these components are water soluble and not cytotoxic to cells.”

Best of both worlds

Lim explains that the macro-component in the bioresin is a mixture of synthetic and biological polymers, so it boasts the best of both worlds. “The PVA-MA has versatile physical and mechanical properties that we can tailor with no batch-to-batch variation,” he says. “And we know that PVA hydrogels are good candidates here because they have previously been used for multiple tissue engineering applications, including neuronal, cartilage and bone.”

The ruthenium-based photo-initiator is also highly efficient at the custom wavelength of 400–450 nm of the DLP machine, which allows the researchers to accurately produce hydrogel structures with superior spatial resolution. What’s more, the structures can be created with a commercial printing machine.

Controlling cellular behaviour

“It is the combination of all these components that allows us to fabricate biofunctional hydrogels with physico-mechanical properties that can be tuned to different tissue engineering applications,” Woodfield told Physics World.

According to Woodfield, the high resolution offered by the technique allows topological features such as gratings or pillars to be created on the surface of DLP 3D-printed constructs. It also allows cells to be embedded within these complex bioresin constructs with high cell viability and without cell settling.

“These features provide the physical as well as spatial cues needed to control cellular behaviour – something, again, that we cannot easily achieve with extrusion bioprinting,” explains Woodfield. “We can also fabricate convoluted structures such as intrinsic vascular networks or cell-laden macro- and microfluidic devices.”

The researchers say they are able to successfully synthesize bone and cartilage tissue using their bioresin. “We now plan to try it out in different applications, such as making liver models and cancer models for high-throughput drug testing and vascular engineering,” says Woodfield.

The research is detailed in the IOP Publishing journal Biofabrication.

- Read our special collection “Frontiers in biofabrication” to learn more about the latest advances in tissue engineering. This article is one of a series of reports highlighting high-impact research published in Biofabrication.