Could physics help us make better bread? Yes, say researchers at the Technical University of Munich in Germany. Their findings – based on a 3D simulation of dough kneading in an industrial kneader – reveal that radial mixing techniques work better than vertical mixing, and that a device with a highly curved spiral arm or two spiral arms that mimic kneading by hand could make dough that is well-aerated, absorbs water well and is elastic.

Bread dough contains four main ingredients: flour, water, salt and a leavening agent such as yeast. Kneading develops the dough’s gluten network and produces a material that behaves in a way that is somewhere between a viscous liquid and an elastic solid when it is deformed. Kneading also incorporates air into the dough, which is important for making it rise once it’s in the oven.

As regular readers of Physics World will recall, both professional and skilled amateur bakers – physicists or not – know that bread dough must be kneaded for just the right amount of time, and in a particular way, to produce the desired texture. Overkneading produces a dense and tight dough that absorbs water less well and does not rise in the oven. Underkneading is just as catastrophic, reducing the dough’s ability to hold onto those precious air bubbles.

Although humans have been making bread for 8000 years, precise information on the changes that occur during kneading and their effect on the dough’s quality is still lacking. Now, however, researchers led by Natalie Germann have performed 3D computer simulations of bread dough that take into account both its viscous and its elastic properties, while also factoring in the free surface that forms between the air and dough when it is kneaded in an industrial 3D spiral kneader.

Model ingredients

To simulate the viscosity of the dough, Germann and colleagues used a single-mode White-Metzner model, which is good at predicting the rheological (flow) behaviour of viscoelastic materials under high shear rates and in all dimensions. They combined this model with a modified Bird-Carreau model, which describes the dough over a wide range of shear rates. This latter model simulates how the dough deforms depending on its viscosity as well as the time it takes for it to relax.

To make their model’s predictions as realistic as possible, the team applied it to computerized geometries based on the dimensions and structures of real-world industrial kneaders. They also conducted experiments aimed at generating realistic input parameters for the model and testing its predictions.

These experiments were carried out using an industrial kneader that consists of a rotating spiral arm and a stationary rod. The researchers prepared their bread dough by mixing 500 g of type-550 wheat flour, 296 g of decalcified water and 9 g of salt in a Diosna SP12 spiral mixer. They pre-mixed the dough for 60 seconds at a speed of 25 Hz before mixing it for 300 seconds at 50 Hz. The kneading arm moved in the same direction as the bowl but at a rotational speed that was 6.5 times higher. To prevent moisture loss and evaporation, the finished dough was covered with a plastic film and allowed to rest for 20 minutes before rheology and tensiometry measurements were performed.

Although Germann and co-workers were able to use a commercial rheometer (an Anton Paar MCR 502) to measure how their dough flowed at 24 °C, measuring the dough’s surface tension proved more difficult. Such measurements could not be done directly because a liquid-air interface is necessary. To overcome this problem, the researchers placed a layer of liquid salt solution on the dough’s surface and measured the surface tension of this solution as it diffused into the liquid phase of the dough.

Migrating and rod-climbing behaviour

The resulting simulations provided valuable insights on the processes occurring inside the dough and on its surface, such as the way air gets incorporated into the dough, and how “dough pockets” – or lumps – form and break up. The model also reproduced some macroscopic dough behaviours that the team observed in their experiments. For example, the elasticity of dough enables it to overcome gravitational and centrifugal forces during kneading, meaning that the dough “migrates” towards the rotating rod before climbing up it. This rod-climbing phenomenon is well-described by the Munich team’s models.

The physics of bread

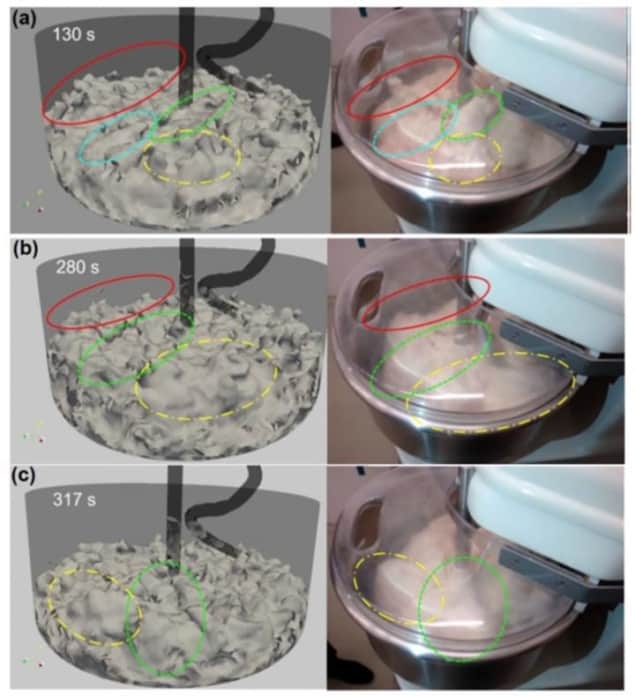

As a final step, the team compared the results from their simulations with screenshots from a high-speed video camera that recorded the dough-kneading process in the laboratory. In these shots, they observed the dough convecting around the inner stationary rod thanks to the rotation of the outer cylindrical bowl. They also observed spiral flow patterns created by the spiral kneading arm located between the stationary rod and the bowl.

In their paper, which has been published in Physics of Fluids, the researchers report that their model accurately predicts the experimentally-observed values for the curvature of the free surface of these spiral flow patterns. They also report being able to predict the formation, extension, and breakup of dough pockets using their numerical approach.

Radial mixing is better

The researchers say that their work represents an advance on previous studies that only considered the purely viscous properties of bread dough. Earlier works also restricted their simulations to simplified geometries, such as a concentric cylinder setup, Germann explains. These simplifications meant that the normal stress effects responsible for the rod-climbing phenomenon were absent, because the elasticity of the material was not considered.

“Our computer simulations showed that vertical mixing isn’t as good as the radial mixing in the spiral kneader we considered in our work,” says Germann. “In the future, mixing performance may be enhanced by using a more highly curved spiral arm or two spiral arms similar to kneading by hand.”