It is virtually impossible to burst a water balloon by throwing it at a wall unless the balloon has been pre-stretched. This is the finding of researchers at Princeton University in the US who have developed and experimentally tested a model that predicts how elastic capsules deform and rupture upon impact. The work could have practical implications in many areas, they say, including in the development of safer riot-control projectiles, better fire-extinguishing techniques and improved safety guidelines that minimize the risk of internal organ damage during car crashes.

From red blood cells to organs like the stomach and bladder, elastic-membraned capsules are ubiquitous in our bodies. Artificially engineered capsules that mimic their biological counterparts are also common, employed in a host of industrial applications. Whether organic or synthetic, these containers exist to transport and deliver liquids that would otherwise be prone to contamination. However, despite the prevalence of such capsules, little is known about the physics of what happens to them on impact.

Throwing water balloons at a wall

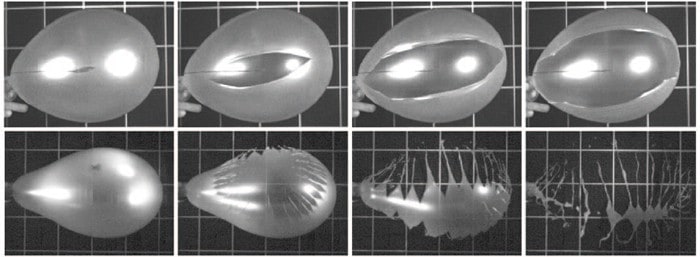

To fill this knowledge gap (and strictly in the interests of science), researchers led by Pierre-Thomas Brun of the Department of Chemical and Biological Engineering at Princeton performed experiments in which they threw custom-made elastomeric capsules and shop-bought water balloons filled with different liquids against a flat wall. They took a sequence of images showing how the capsules and balloons deformed as the impact velocity increased from roughly 6 m/s to nearly 40 m/s.

The researchers liken the impact of a capsule to that of a droplet falling onto a surface, but with two alterations. The first is that the capsule’s surface modulus (a parameter that depends on the capsule material’s shear modulus and thickness) replaces the drop’s surface tension. The second is that while the impacts of capsules may produce large deformations similar to those seen in drop impacts, capsules – unlike drops – can burst open and release their contents. A capsule also deforms as a function of its Reynolds number, which describes the flow of a fluid and expresses the ratio of the fluid’s inertial and viscous forces, and an elastic-shell equivalent of its Weber number – a measure of a fluid’s inertia compared to its surface tension.

Pre-stretching required

Based on their modified liquid-droplet analogy, Brun and colleagues created a model that quantitatively predicts the maximal deformation of a capsule or water balloon, and its possible rupture, upon impact.

“We found that to burst an elastic capsule, we need to pre-stretch it by filling it with a volume of liquid that exceeds the volume of the capsule at rest,” Brun tells Physics World. “We can now predict how much inflation is needed to break a capsule in a given impact speed range.”

Balloon bursts approach the speed of sound

Only bursting when intended

According to the Princeton researchers, their model could make it easier to design capsules that burst only when intended. Possible applications include safer riot-control projectiles that would burst at lower impact speeds, thus avoiding serious injury to the people targeted, and fire-extinguishing elastomer capsules that could be thrown onto small domestic fires or released from aircraft to fight large-scale conflagrations. The model could even help devise safety guidelines that decrease the risk of internal organs bursting in a car crash, they say.

Although the present work, which is detailed in Nature Physics, focused on macroscopic objects, the researchers believe their model could be extended to the microscale. “The simple analogy between drops and elastic capsules that we have demonstrated could indeed come in useful for understanding other complex fluid-structure interactions involving capsules – for instance the deformation of microcapsules recently observed in microfluid channels,” Brun says. “Here the source of the deformations would come from viscous effects imparted by the surrounding fluid.”