Scientists have been trying for many years to develop new ways of converting mechanical energy from the environment into electrical energy. Now, researchers in the US and South Korea have found that, at very small scales, they can generate record levels of power by twisting yarns made from carbon nanotubes in contact with an electrolyte. They say that their “twistron” devices are well suited to powering remote sensors in industrial and other equipment, as well as potentially being able to tap energy from ocean waves and bodily movement.

Mechanical energy is usually converted into electrical energy using generators, devices that exploit the principle of electromagnetic induction to create a current by moving a conductor in a magnetic field. However, while able to approach 100% efficiency at large scales, generators become increasingly hard to build, and as such inefficient, when they are just a few millimetres or centimetres in size.

It is at this scale that the twistron is designed to operate. Developed by Ray Baughman of the University of Texas at Dallas and colleagues, the new device generates more energy per unit weight than previous energy harvesters operating between 1 Hz and a few tens of hertz. As the researchers point out, this frequency range encompasses many back-and-forth motions in nature, including human walking and breathing.

Capacitive effect

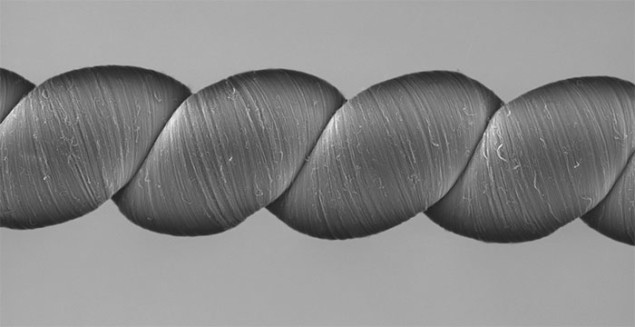

Each twistron is made by spinning several billion carbon nanotubes – hollow cylinders with carbon walls just one atom thick – into high-strength yarns a few tens or hundreds of microns in diameter and surrounding them with an electrolyte. The water in the electrolyte creates a very thin barrier between electrons on the surface of the yarn and ions in the electrolyte, thereby forming a capacitor that needs no external charging. Twisting the fibre then brings the charges on the yarn closer together, so reducing the device’s capacitance and increasing the voltage in an attached electrical circuit, causing a current to flow.

Baughman’s team has designed the twistron so that it twists when stretched, given that the energy from most external sources of motion can best be tapped through a stretching force. To do this, the researchers spin the yarns so much during their manufacture that they form a coil.

They found that twistrons can generate about 250 W of peak electrical power for each kilogram of yarn. So far they have limited themselves to very small amounts of yarn, but using a twistron weighing about 35 mg – about the mass of two houseflies – they were able to power an LED. They reckon that this output would also be enough to transmit a radio-frequency signal carrying 2 kB of information over 100 m about once every 10 s. This, they argue, makes their technology well suited to powering sensors in the wirelessly connected network of devices known as the Internet of Things.

Artificial muscle

In this case, they explain, twistrons would be coated with an electrolyte in the form of a gel, and could be hooked up to a polymer-based artificial muscle that contracts and expands in response to temperature fluctuations in the environment – so removing the need to install and replace batteries in remote sensors. Although they achieved peak powers using fluctuations of more than 100 °C, the researchers say that the muscles can respond to changes of just a few degrees if they are made long enough.

Tom Krupenkin of the University of Wisconsin–Madison, who was not involved with the research, agrees that providing power to mobile sensors is “one of the obvious possibilities” for twistrons. He also believes that the new devices could be incorporated into clothing, using the up-and-down motion of the chest to power a heart monitor, for example. But cautions that in this case the power available is likely to be very limited – “well below a watt”, he says.

One obvious application for twistrons is to generate electricity from ocean waves, since in this case the seawater would serve as the electrolyte and there would be no need to coat the yarns. Group member Shi Hyeong Kim of the University of Texas demonstrated this principle by installing a 10 cm-long, 1 mg twistron in the sea off the coast of South Korea, attaching the device’s lower end to a weight on the seabed and its upper end to a balloon on the water’s surface. He found that the up-and-down motion of the balloon stretched the twistron by up to a quarter, generating an average power of 1.8 μW in the process.

Major hurdles

Kim’s colleague Carter Haines, also at the University of Texas, acknowledges that the technology currently faces two major hurdles. One of these is efficiency – the twistrons typically converting only around 1% of mechanical energy into electricity. Rival “triboelectric” devices, in contrast, can turn about 10% of the energy used to rub two different materials together into electrical energy.

Potentially even more problematic, however, is the manufacturing process, which is very energy intensive and therefore extremely expensive. According to Matteo Pasquali, who works on yarn spinning at Rice University in the US, production costs would need to fall by “about three orders of magnitude below current R&D prices” – to a few hundred dollars per kilogram – if twistron wave power is to be viable at the megawatt scale.

As such, says Haines, twistrons might be best suited to niche markets. For example, he says that they could provide maintenance-free power for buoys that monitor the climate or track the movement of fish. Nevertheless, he and his colleagues are trying to raise efficiencies and reduce costs. “Our goal right now is to use the same approach with lower cost materials,” he says.

The research is described in Science.