A recently discovered form of lignin known as catechyl (or C-) lignin could be used in biorefineries to produce biofuel. This is the new finding from a team of researchers at the University of Wisconsin-Madison who say that C-lignin can be readily processed to yield 90% of valuable commodity chemicals – something that is unimaginable for ordinary lignin.

Lignin is a major component of plant biomass and the most abundant source of renewable aromatics (carbon-based materials usually derived from petroleum). The problem is that it is difficult to produce sugars for biofuels, and then valuable products, from the lignin residue because it contains several types of monomers and distorts when chemically processed. Paper factories, for example, often simply incinerate it and use it for fuel rather than try to convert it into commercial bioproducts.

Researchers led by John Ralph of the Great Lakes Bioenergy Research Center and the Wisconsin Energy Institute are now saying that there exists a natural form of lignin from which it is possible to obtain 90% yields of phenolic (catechol-type) monomers with a single compound accounting for most of the product.

“We’ve come up with ‘ideotype’ for lignin, that is, an archetype for a lignin that is ideal for the biorefinery,” Ralph tells Physics World. “This C-lignin can be readily processed to produce potentially valuable commodity chemicals in high yields.”

What is C-lignin?

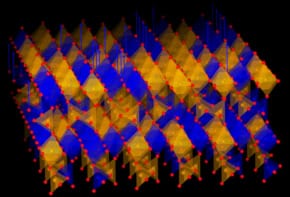

C-lignin is essentially a benzodioxane homopolymer and derives from caffeyl alcohol, a hydroxycinnamyl alcohol that is not one of the normal monolignols (sinapyl, coniferyl and p-coumaryl alcohols) from which lignin is usually derived in plants, he explains. “Together with colleagues at the University of North Texas, we originally discovered this unusual lignin in the seed coats of vanilla.”

“In previous research, we unexpectedly found that caffeyl alcohol undergoes the radical coupling that characterizes lignification in essentially only one way – by so-called β-O-4 coupling. The result is C-lignin – a linear and homogenous polymer with only one kind of interunit (ether) linkage, which means that it can be cleanly cleaved into monomer units (using a simple depolymerisation chemical treatment). These ‘building blocks’ can be transformed in different ways to produce a variety of products.”

Another good thing about C-lignin is that its structure remains stable after chemical pre-processing unlike ordinary lignin, explains study first author Yanding Li. This is because it contains a 3-OH groups instead of the usual 3-OMe ones. These allow for an internal trapping reaction post-radical coupling that re-aromatizes the intermediate product to produce benzodioxane rings in each unit instead of the normal β-ether (which has a non-cyclic sidechain), protecting the sensitive benzylic-OH.

“When plants are refined into biofuels, the lignin first gets stripped away, leaving sugars to be converted into the bioproducts. This pre-treatment usually causes lignin to ball up into a tangled mess. C-lignin’s structure survives even the harshest pre-treatments, however, and it is even resistant to concentrated sulphuric acid.”

90% yield

In their experiments, Ralph, Li and colleagues subjected C-lignin to hydrogenolysis – a technique to deconstruct lignin developed at UW-Madison back in 1938 by the chemist Homer Adkins. The technique produces a simple pair of monomers in 90% yield. “Choosing the right catalysts can narrow this down to a single monomer,” says Ralph.

“Our work provides a new way to produce chemicals and intermediates, such as catechols, sustainably form natural resources and we hope that it will spur interest in using such compounds to produce polymers and bioproducts. It could also allow researchers to think further about how other lignins might be used in bioprocessing.”

Making artificial wood on the large scale

The team, reporting its work in Science Advances 10.1126/sciadv.aau2968, says that it is now working on isolating the genetic code of C-lignin and inserting this lignin into “normal” bioenergy crop plants that might then be cultivated on a large scale. “To date, genetic engineering attempts to do this have not been particularly successful,” says Ralph

“We are also trying to produce C-lignin from other biomass waste sources,” he reveals.