A new cost-effective and efficient supercapacitor made from carbon black and cement could store a day’s worth of energy in the concrete foundation of a building or provide contactless recharging for electric cars as they travel across it. The device could also facilitate the use of renewable energy sources such as solar, wind and tidal power, according to the researchers at the Massachusetts Institute of Technology (MIT) and the Wyss Institute, both in the US, who developed it.

Supercapacitors are technically known as electric double-layer or electrochemical capacitors, and their capabilities fall somewhere between those of batteries and conventional (dielectric) capacitors. Though less good at storing charge than batteries, supercapacitors are better than conventional capacitors in this respect thanks to their porous electrodes, which have surface areas as large as several square kilometres. The double layer that forms at the electrolyte-electrode interface of such devices when a voltage is applied further increases the amount of charge they can store.

Supercapacitors also have some advantages over batteries. Whereas batteries can take hours to charge and discharge, supercapacitors do it in minutes. They also have a much longer lifespan, lasting for millions of cycles rather than thousands. And unlike batteries, which work through chemical reactions, supercapacitors store energy in the form of electrically charged ions that assemble on the surfaces of their electrodes.

Extremely high internal surface area

The new device, developed by a team led by Franz-Josef Ulm, Admir Masic and Yang-Shao Horn, contains a cement-based material that boasts an extremely high internal surface area. The researched achieved this by starting with a dry cement mix containing carbon black, which resembles very fine charcoal. To this mix, they added water and superplasticizers – a standard water-reducing admixture in concrete production. As the water reacts with the cement, it naturally forms a branching network of pores within the structure, and the carbon migrates into these pores to form wiry filaments with a fractal-like structure. It is this dense, interconnected, network structure that provides the material with its extremely large surface area.

“We fill the fresh material into plastic tubes and let them harden for at least 28 days,” explains Ulm. “We then cut the samples into electrode-sized chunks, soak these electrodes in a standard electrolyte solution (potassium chloride) and build a supercapacitor out of two electrodes separated by an insulating membrane.”

The researchers then polarize the electrodes by connecting one electrode to a positive charge and the other to a negative charge. During charging, positively charged ions from the electrolyte accumulate on the negatively-charged volumetric carbon wire, while negatively-charged ions accumulate on the positively-charged carbon wire.

A day’s worth of energy

With the membrane in the way, the charged ions cannot move between electrodes. This imbalance produces the electric field that charges the superconductor. “The fact that the volumetric wire fills the space available to it – something we confirmed with EDS-Raman spectroscopy – allows us to store a lot of energy on the extremely large surface of the carbon black,” says Ulm. “When we then disconnect the energy source from the supercapacitor, the stored energy is released, and can thus provide the power for a variety of applications.”

According to their calculations, which they detail in PNAS, a block of the material measuring 45 m3 (equivalent to a 3.55 m cube), would be able to store about 10 kWh of energy. This is about the same as the average daily electricity consumption of a typical household. A house built with foundations that contain this carbon-concrete composite could therefore store a day’s worth of energy – produced by solar panels, for example – and release it when needed. The material might also be incorporated into intermittent electricity generators such as wind turbines, which could then store energy in their bases and release it during down periods.

Another potential application for the supercapacitor – albeit a high-end one – would be to add it to concrete roadways. These super-roads could then store energy (perhaps produced by solar panels located alongside them) and deliver it to passing electric vehicles via electromagnetic induction. This technology is fundamentally the same as that used to wirelessly recharge mobile phones, and the researchers say it could also be used to recharge electric vehicles when they are not moving — in a car park, for instance.

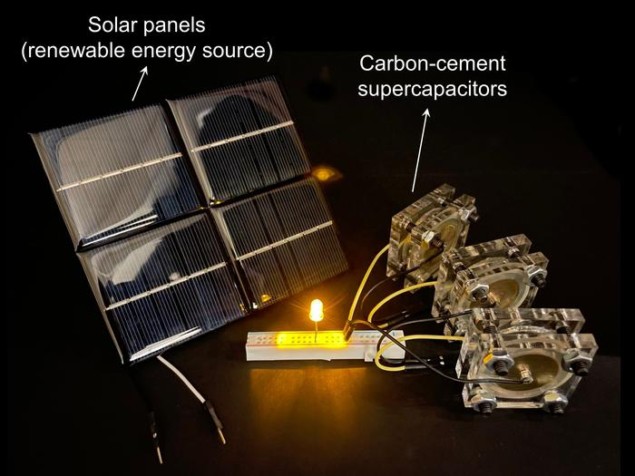

More near-term uses, they add, might be in buildings far from the electricity grid, which could be powered using solar panels attached to the supercapacitors.

Very scalable system

The system is very scalable, says Ulm, since the energy-storage capacity increases in proportion with the volume of the electrodes. “You can go from 1-millimetre-thick electrodes to 1-metre-thick electrodes, and by doing so basically you can scale the energy storage capacity from lighting an LED for a few seconds, to powering a whole house,” he explains. Depending on the properties required for a given application, the system could be tuned by adjusting the mixture, he adds. For a vehicle-charging road, very fast charging and discharging rates would be needed, while for powering a home “you have the whole day to charge it up,” so slower-charging material could be used.

Non-toxic supercapacitors go fully recyclable

“The fact that the constituent materials are so readily available opens up a new way to rethink energy storage solutions,” Ulm tells Physics World. “Concrete is, after water, the most consumed material on Earth, but it comes at a non-negligible environmental cost, since roughly 8% of worldwide CO2 emissions result from the 4 gigatons of the annual global worldwide production. Our overall focus was therefore to make concrete a multifunctional material that could provide an additional useful societal function.”

Energy storage is of critical importance today if we are to curb the impact of climate change, he notes, and previous studies have shown that a cement-carbon mixture can be used to make an electron-conducting cement. Electrical conductivity is not enough, however, to store energy. “We hypothesized that hydrating the hydrophilic cement in the presence of the hydrophobic carbon black should naturally provide the two other criteria that are needed: storage- and transport-porosity,” Ulm says.

The researchers’ immediate focus is to make a supercapacitor that can store the same amount of charge as a 12V battery. “We consider this device as the elementary brick towards more advanced devices,” Ulm says.