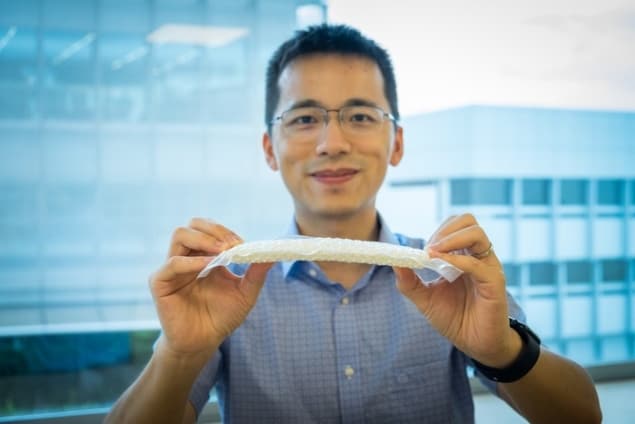

Physicists have designed a chain mail fabric that is easily foldable in normal conditions but becomes much stiffer when compressed. The lightweight and tuneable fabric was developed by Yifan Wang and colleagues at Singapore’s Nanyang Technological University and the California Institute of Technology. It comprises an intricate structure of interlocking, 3D-printed components – and undergoes a sudden phase transition when pressure is applied to its exterior.

From medieval chain mail armour to woven Kevlar sheets, structured fabrics have a diverse range of useful properties that include high impact resistance, heat regulation, and electrical conductivity. These properties arise from tailored combinations of material properties and component geometries. Building on existing designs of these materials, researchers are creating new smart fabrics that can vary their physical properties in response to environmental stimuli.

Wang’s team created its fabric by 3D printing a chain mail from a nylon plastic polymer. Their design comprises a lattice of interlinking, centimetre-sized components, each shaped as the hollow frame of an octahedron. Under ambient conditions, the fabric can be easily folded and deformed into complex shapes – but this changes dramatically when the fabric is encased in a flexible plastic envelope and then compacted by evacuating the envelope.

Jamming transition

Putting pressure on the fabric in this way raises the packing density of their chain mail: increasing the level of contact between each component and its neighbours. As a result, the material undergoes a jamming phase transition, where the hollow particles became rigidly interlocked – making them far more resistant to bending and deformation.

Wang and colleagues determined that their fabric could carry a load of over 50 times its own weight when stiffened, and also displayed just 17% of the deformation of its unconfined state when impacted by a fast-moving steel ball. Altogether, these experiments showed that the chain mail becomes over 25 times stiffer, when confined at pressures of roughly 93 kPa. In addition, the team showed that lattices comprised of aluminium particles had the same flexibility as nylon but could be jammed into far stiffer structures than their nylon counterparts.

How can powered exoskeletons restore walking ability after stroke?

The researchers say that if the components could be fabricated on smaller scales, these fabrics could have numerous applications: including stab- and bullet-proof vests, protection for high-contact sports, and wearable exoskeletons. The latter could provide enhanced mobility for elderly people or extra support for workers who lift heavy loads.

Elsewhere, the fabrics could be used to develop electrical devices with highly touch-sensitive interfaces. Wang’s team now hope to explore the potential for simpler, alternative stiffening mechanisms including magnetism, electrical currents, and temperature.

The research is described in Nature.