Cryogenic technology is making it possible for liquid air, nitrogen and methane – including methane derived from cow slurry – to play roles in combating global warming. Andy Extance reports

Although climate change is undoubtedly an urgent problem for humanity, there is at least one climate-related context where it’s appropriate to use the word “bullshit”. That’s when the subject is methane. When bacteria break down the pungent by-products of cattle farming, methane is released in vast quantities. Since methane is a greenhouse gas around 30 times more potent over 100 years than the main warming villain, carbon dioxide, these agricultural emissions pose a sticky environmental problem.

For entrepreneur Chris Mann, though, they are also an opportunity. When he moved to rural Cornwall in south-west England, he learned that local farmers sometimes feed slurry waste into anaerobic digesters (ADs). These devices burn the methane they produce – turning it into less potent carbon dioxide – and generate electricity. However, most farmers are not close enough to connections that can fully accept that power. One of Mann’s neighbours, for example, devised a cheap AD, but could only sell a fifth of the electricity he produced.

That waste inspired Mann to co-found Bennamann, which develops cryogenic techniques for storing methane so that it can be used to generate energy where and when it is most needed. But the story of Mann, his company and his neighbour’s cow dung is just one of several ways in which cryogenics might help clean energy fit into existing electricity-generation systems.

It is well known that both solar and wind power don’t necessarily generate electricity when people want to use it. “An important part of the electricity system is missing,” explains Gareth Brett, chief executive officer of London, UK-based Highview Power, which is also developing cryogenic energy storage (CES) technologies. “To balance the grid, we need long-duration storage – four hours, or maybe eight.”

Batteries are good for high-power, short-duration storage, but become too expensive and large for longer durations, Brett asserts. Although it is only one of many possible solutions being explored by companies, academics and government bodies, CES does offer certain advantages. In particular, CES systems can be very compact, with liquid air being around 800 times denser than the gas. Hence, CES systems make it possible not only to store renewably generated energy, but also to supply it at the right time and in the right place. That includes in vehicles as they travel, or in remote locations.

How it works

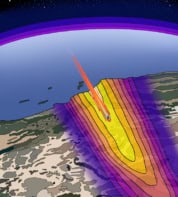

Mann compares cryogenic cooling to a “pressure cooker in reverse”. The main idea is to slow the rate at which gas boils off by lowering its pressure and temperature, typically to below 125 K. To minimize the energy required, engineers seek to keep components of a gas’s internal energy – the entropy and/or enthalpy – constant. Ideally, there would be no transfer of heat to or from the surroundings. In practice, even the best systems never quite achieve this. Decades of R&D have nevertheless produced efficient, well-established liquefaction cycles for cryogenically cooled gases, with multiple stages of compression and then expansion into low-pressure chambers.

One of these processes, the Claude cycle for making liquid air, is central to Highview Power’s business. Highview exploits cheap electricity – usually at night-time – to power a modified Claude cycle, liquefying air at around 80 K. This liquid air is stored in low-pressure, vacuum-insulated tanks, like those in the industrial-gas sector, Brett explains. Then, when electricity demand is high, they pump up pressures and evaporate liquid air through a heat exchanger. There, heat from ambient air or hotter air – released either by the refrigeration cycle itself or by a neighbouring industrial process – turns liquid air back into gas. That expansion drives an electricity-generating turbine.

Brett claims that Highview’s liquid-air energy storage (LAES) system offers a storage density and self-discharge losses similar to those of lithium-ion batteries, but without batteries’ potentially hazardous electrolytes and heavy metals. The system also exploits relatively simple and readily recyclable steel systems already used in industry. Companies involved in electricity generation, or any large process plant, have the know-how required to maintain Highview’s LAES systems, Brett says. These systems have “about the same longevity” as other grid-scale power plants, he adds. Such claims are now being tested: Highview opened a 5 MW/15 MWh demonstration plant in Bury, UK, in June 2018, following an earlier 350 kW/2.5 MWh pilot. The company also hopes to announce a 50 MW/250 MWh system for an undisclosed customer “in the next few months”, according to Brett.

Cold capture

Like Brett, Judith Evans is interested in CES systems that mainly use existing technologies. As a refrigeration engineer at London South Bank University, Evans co-ordinates the European Union-funded CryoHub project, involving partners from five countries. They are collaborating to build a demonstration system that integrates renewable energy generation and CES with a large cold store owned by Frigologix, a storage and distribution firm based in Lommel, Belgium. The benefits of integrating with a cold store stem from the opportunity to recycle cold and heat. By itself, CES generally only offers 25% “round trip efficiency” – the ratio of energy generation to consumption. Adding a thermal store to capture the cold generated when the liquefied gas evaporates can at least double this.

Whereas Highview reuses its waste cold during the next liquefaction cycle, CryoHub seeks to exploit it in cold storage. A major goal of CryoHub, therefore, is to improve existing cold-storage systems. “One issue is cost,” Evans says. “You can make an amazing thermal store if you’re prepared to put a lot of money into it, but to make an economic case you have to reduce the cost as much as possible.” According to the CryoHub team’s models, which are due to enter testing soon, the very best round-trip efficiency could be as much as 80%. This would be challenging to achieve in practice, but some improvements are definitely necessary, Evans says. “If you’re going to compete purely on energy storage, you have to get your round-trip efficiency as high as you possibly can,” she explains.

On the road

Liquid air produced for cooling can also be used for other purposes. Evans notes that one CryoHub partner, the Paris-based industrial gas firm Air Liquide, already uses cryogenics in vehicles or for transporting goods at multiple temperatures. Currently, they use liquid nitrogen, but might be able to convert systems to liquid air.

Another company with an interest in putting liquid-nitrogen cooling on the road is Dearman, a London-based firm set up in 2011 to exploit the liquid-nitrogen-powered engine invented by founder Peter Dearman. “You could regard liquid nitrogen as a vector for moving grid energy onto a moving truck,” says Chris Owen, Dearman’s head of cryogenics. “If you look at the overall cycle, including the production of liquid nitrogen, we release roughly a tenth of the carbon dioxide as a diesel engine on a truck.”

Of course, this calculation relies on using renewable energy to liquefy the nitrogen. As with everything in the energy business, there is no free lunch. A Dearman engine generates a maximum of 214 Wh/kg from liquid nitrogen, while the liquefaction process itself requires 400 Wh/kg. In Dearman’s experience, making that loss financially viable means producing liquid nitrogen only when the cost of renewable energy dips to half the peak electricity cost for the day. “It’s finding the right environment where power price swings are as big as we need them to be to make it profitable,” Owen says.

With this in mind, Dearman is currently focusing on replacing the diesel engines found in trucks’ refrigeration units. Such engines are almost unregulated, and contribute greatly to particulate air pollution in cities. “The city of Los Angeles could lose a third of its particulate load if it replaces its current refrigeration unit engines with Dearman engines,” Owen says. Dearman has supplied engines for this application to UK food retailers and producers including Sainsbury’s, Marks and Spencer and Unilever. It also hopes to extend the approach to train and bus air conditioning.

Reducing greenhouse gases

Back in Cornwall, Mann and his company also hope to displace dirty diesel. But they want to use cryogenic biomethane rather than liquid nitrogen, as fuel for the trucks themselves rather than for the refrigeration units they carry. Liquid natural gas (LNG)-powered trucks already offer some local pollution-reduction benefits, but extracting and burning this fossil fuel still adds to overall greenhouse-gas emissions. Moreover, as the stored fuel expands, United Nations regulations allow trucks to vent their fuel tanks after five days, bringing flammability hazards as well as threats to the climate.

Bennamann has therefore developed a cryogenic storage system that never vents to air. Instead, it uses released methane to power an engine or fuel cell to sustain low temperatures. This contained pressure release enables much lower storage pressures than for LNG. Tanks can therefore be larger, and the methane kept cooler, making it denser. This, in turn, lets trucks carry more cryogenic fuel, enabling them to travel between 300–500 km on a single tank, Mann says. “This is where the market needs to be to compete with diesel,” he adds.

Bennamann’s technology also offers permanent storage tanks for farms, and their prototype has enabled Mann’s neighbour to sell all his AD-powered electricity, rather than just some of it. But Mann is more enthusiastic about fuelling trucks with gas from cow slurry. “If you do that, then the biomethane has significantly more value,” he says. “You don’t need a subsidy to make it profitable. I think it’s revolutionary for small farms.” However, Mann estimates that the company’s products won’t be available for two years.

On its own, even a revolution in cryogenic gas technologies would not resolve the enormous challenge that climate change poses to humanity. Dearman’s Owen, however, notes that they can definitely contribute. “It’s a problem we all accept is going to be solved by a lot of small changes rather than one big one,” he says. Replacing diesel used in refrigeration engines “is one small change that moves us in a dramatically right direction”, he adds. CES and biomethane truck fuel could well provide a similar nudge. After all, like slurry in a digester, every little bit helps.