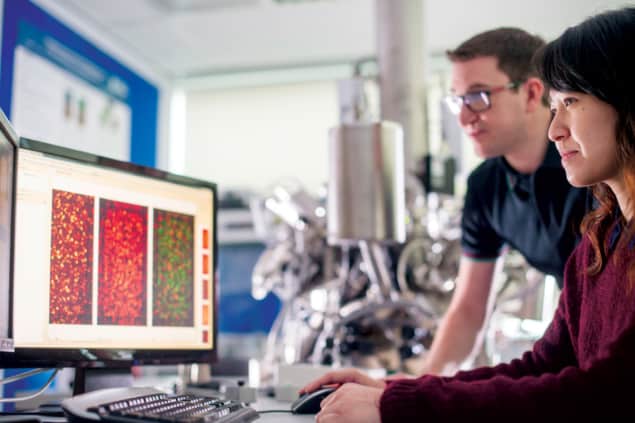

David J Scurr and Matthew Piggott describe how time-of-flight secondary ion mass spectrometry is helping scientists in a variety of industries to understand problems related to materials science

Materials characterization has long been a go-to approach to support hi-tech manufacturing. The increasing complexity of technologies such as pharmaceutical devices and electronic systems, coupled with the engineering challenges emerging from an ever-changing commercial landscape, frequently demand advanced characterization techniques and methodologies. The nature of these industrial challenges is incredibly varied, but the specific technique we use, known as time-of-flight secondary ion mass spectrometry (ToF-SIMS), has proven remarkably adaptable in investigating a wide range of questions, from contaminant identification to mapping the skin permeation of cosmetics and pharmaceuticals.

The ToF-SIMS technique

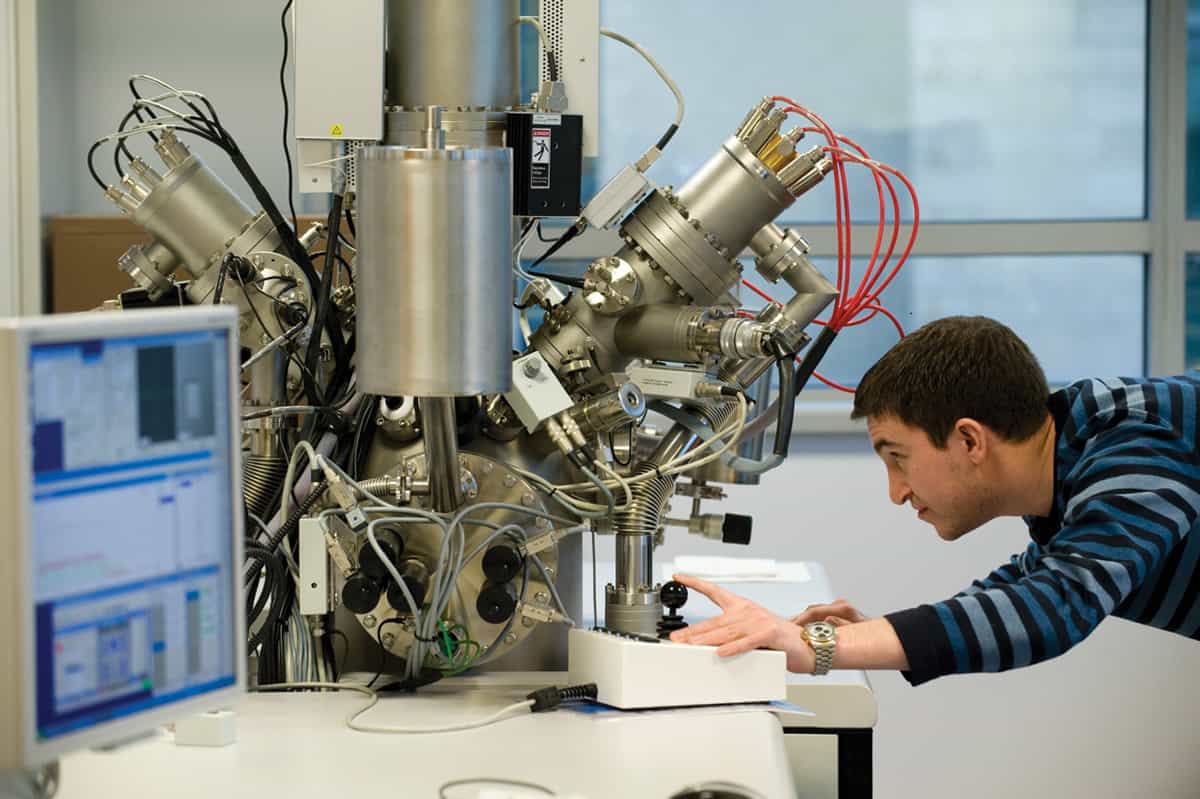

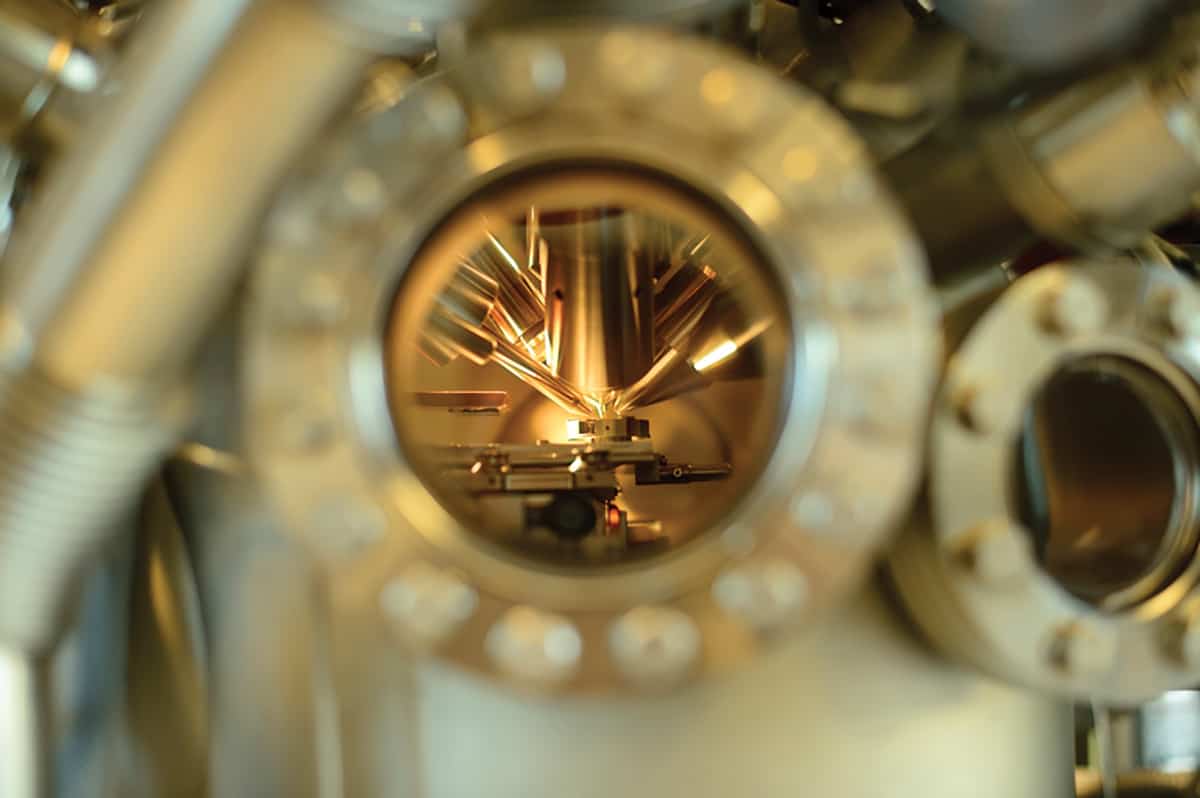

ToF-SIMS is a sensitive surface-analysis technique that provides very detailed information about chemicals present in the upper few nanometres of samples (often referred to as static SIMS). In the technique, high-energy (typically up to 30 keV) beams of positive ions are directed at the sample’s surface, thereby liberating secondary ions. These ions are then accelerated into a time-of-flight analyser and separated according to their mass, producing a spectrum that indicates the sample’s chemical make-up.

ToF-SIMS can be applied to conduct surface spectrometry, but it can also be used to generate a chemical image of the entire sample, in which each pixel contains a full mass spectrum of the chemicals present at that location. This is known as hyperspectral data, and it can be obtained by rastering the primary ion beam over the sample surface. Samples can also be interrogated in 3D (known as depth profiling or dynamic SIMS) by employing an etching ion beam capable of sputtering layers of material. Depending upon the type of instrument configuration, either the sputtered material or the underlying exposed material is available for analysis. The technique can provide highly specific chemical information, including molecular information, and it enables researchers to detect numerous species at once – a capability known as parallel detection. The instrument is operated under ultrahigh vacuum (in the range of 1 × 10–9 mbar) and serves as a materials characterization tool for scientists in many disciplines, with applications ranging across physics, chemistry, engineering, life sciences, pharmacy and beyond.

In the early application of static SIMS, from the late 1960s, the technique employed monatomic ion species such as Ar+ and Cs+ as the primary ion beam. This tends to promote the fragmentation of molecules on the sample surface, making the results more difficult to interpret. Even so, these early ToF-SIMS instruments found a major role in several fields – particularly the semiconductor industry, where elemental species such as Si+, Ga+ and Li+ are of great interest. By employing an etching ion beam, these structures could also be interrogated in 3D, making it possible to assess any buried interfaces.

of Nottingham, UK. (Courtesy: Wellcome Trust)

Monatomic ion beams continue to have value today (for instance in the battery technologies industry), but the highly fragmented nature of the secondary ions they generate renders them unsuitable for analysing organic samples. For this category of measurements, higher-mass ions – ideally ionic molecules – are required, and beams of gold and bismuth clusters (typically 25 keV Au3+ and Bi3+) are now routinely used to reduce the degree of fragmentation of secondary ions and make it possible to liberate organic molecular ions from the sample surface. Similarly, etching beams made up of monatomic ions are highly effective for depth profiling inorganic materials, but for organic materials the recent development of gas cluster ion beams has been a game-changer, enabling a new range of materials to be interrogated by ToF-SIMS.

These advances have expanded the technique’s range of applications and persuaded scientists in a variety of industrial sectors to take advantage of its capabilities. For more than 17 years, researchers at the University of Nottingham in the UK have used this instrument in collaboration with industry scientists to investigate technical challenges in the pharmaceutical, aerospace, cosmetics, petrochemical and additive manufacturing sectors (to name just a few). A few case studies illustrate both the breadth of this work and the versatility of the technique.

Identifying textile contaminants

In the large-scale manufacture of textiles, contamination during production can lead to a catastrophic reduction in the material’s aesthetics, requiring the process to be stopped and the material itself to be scrapped. This can be very costly. At Nottingham, we performed a project with a local textile manufacturer, Guilford Europe, to help its employees understand the chemical nature of deposits that were appearing intermittently on materials during production. These deposits were visible to the naked eye, and because they were embedded within the weave of the fabric, they were not easy to remove. Their small size – around 200–300 µm in diameter – also made them poor candidates for conventional materials analysis testing methods. They were, however, within the size amenable to ToF-SIMS analysis, and because the nature of the deposits was entirely unknown, the problem of identifying them was well suited to the instrument’s parallel detection capabilities.

The team at Nottingham’s ToF-SIMS facility began by analysing a reference library of ~50 materials used in this specific manufacturing process. Next, we compared these results to spectra taken of deposit samples. Analysis of the contaminant data showed a series of ions, including the molecular ion, corresponding to the chemical make-up of a specific drying agent used in Guilford’s facility. This information was passed to the people in charge of the production process, with the suggestion that this particular drying agent was not being fully washed from the product before the next stage of manufacture. It was postulated that this agent would therefore build up within air ducts in the manufacturing facility, such that small quantities would occasionally be blown into the product during manufacture.

After Guilford implemented a more rigorous washing process these contaminants were no longer found. The reference library of raw materials also came in useful for analysing samples associated with later contamination events, making it possible, for example, to identify the chemical constituents of leaking pipework and deposits caused by broken machine bearings.

Getting under the skin

ToF-SIMS can also discern molecular ions for active pharmaceutical agents (APIs), as well as diagnostic ions for polymer delivery systems, surfactants and stabilizers. As such it has found many applications within the pharmaceutical sector, including the analysis of API-containing micro- and nanoparticles, biomedical implants, tablets and topical medicines. In addition to the pharmaceutical sector, the permeation of topically applied agents is also relevant to the agrochemical and cosmetics industries.

At Nottingham, the research group of one of us (DJS) has undertaken research on skin permeation in collaboration with partners at Dermal Technologies Laboratory and Walgreen Boots Alliance. Some of the agents investigated include chlorhexidine, a commonly used antibacterial agent; imiquimod, a topical treatment for a type of skin cancer known as basal-cell carcinoma; and vitamin C, which is commonly applied to skin as a cosmetic agent.

The team’s starting point was a set of adhesive tapes containing skin samples. These skin tape strips can be analysed to chemically illustrate the composition of the adhesive, the skin itself and any exogenous materials. The standard analysis technique is high-performance liquid chromatography (HPLC), but this requires samples to be amalgamated and so cannot provide depth-resolved data. HPLC also does not provide any information about the spatial distribution of chemicals, which can be critical for killing bacteria or treating cancerous tissue.

In contrast, using the ToF-SIMS technique with gas-cluster ion beams makes it possible both to analyse the upper surface of a given sample and to create a depth profile of ex situ skin, producing a 3D rendering of the distribution of endogenous and exogenous chemistries. Such renderings improve our understanding of how (for example) cosmetic agents are delivered to the uppermost layer of the skin, and these collaborative works will ultimately enable clinicians and others to deliver antibacterial agents, APIs and cosmetics to the skin more effectively.

Cleaner fossil energy

The cleanliness (or otherwise) of diesel engines has been a hot topic in recent years. One aspect of the challenge concerns the formation of internal diesel injector deposits (IDIDs), which are commonly associated with engine problems such as sticking injectors, loss of power and increases in emissions and fuel consumption. Changes in emission regulations aimed at cleaning up diesel engines mean that the engines now operate under more severe conditions, including higher temperatures and pressures, than was once the case; unfortunately, these conditions also make IDIDs more likely to form. Novel fuel additives and other strategies may be able to combat IDID formation, but before appropriate additives and countermeasures can be developed, the nature of the IDIDs must first be analysed.

Pioneering work aimed at understanding the factors behind these deposits has been undertaken by a multidisciplinary team drawn from academics at Nottingham and industry scientists at Innospec. As the IDIDs are non-soluble they are not amenable to conventional mass spectrometric techniques; however, as ToF-SIMS bombards samples with ion beams rather than dissolving them, it is possible to use this technique to interrogate the chemistry of these samples. Before this series of experiments, the deposits were thought to be a single chemical entity, but this hypothesis has now been falsified. In fact, ToF-SIMS depth profiling has shown that IDIDs incorporate a range of stratified layers, where the chemical makeup is dominated by carbon, sodium, potassium, calcium and sulphur. Innospec will use this information to produce preventative additive packages to reduce the incidence of IDIDs.

Despite the advantages of ToF-SIMS, the technique’s limited mass-resolving power does, in some cases, restrict its range of applications (both industrial and otherwise). As such, Ian Gilmore of the UK’s National Physical Laboratory proposed a new concept that aimed to combine the highest possible simultaneous spatial- and mass-resolving capabilities into a single instrument.

The project team to develop this new instrument consisted of members affiliated with the University of Nottingham and three commercial entities: the pharmaceutical company GlaxoSmithKline; a specialist electronics manufacturer, ION-TOF; and a biotech firm, Thermo Fisher Scientific. The capabilities of the new instrument, known as 3D OrbiSIMS or HybridSIMS, are ideally suited to analysing complex organic and biological samples (2017 Nature Methods 14 1175). Thanks to a recent grant from the UK’s Engineering and Physical Sciences Research Council, a HybridSIMS will soon be located at Nottingham, where it will become the first instrument of its kind to exist in an academic setting while also supporting a wide range of industrial collaborations. We look forward to seeing what systems and problems it will investigate next, and welcome any suggestions.