An international team of researchers has produced a stack of diamond micro-lenses precise enough to be compatible with the latest generation of X-ray sources. Physicists led by Polina Medvedskaya at Immanuel Kant Baltic Federal University in Russia developed the intricate structures using ion-beam lithography – a novel approach that could open up new opportunities for compact X-ray microscopy.

Today’s “fourth generation” synchrotrons produce high-quality beams of X-rays that are ideal for imaging. However, advances in the lenses used to shape and condition X-rays have not kept pace with advances in synchrotron technology. When powerful X-ray beams interact with even nanoscale imperfections in lenses, the resulting aberrations fundamentally limit the resolution of the resulting images. This makes it difficult to fully exploit the advantages of modern synchrotrons for X-ray microscopy.

Medvedskaya’s team suggest that this problem could be solved using lenses made from diamond, which has a continuous structure that limits any graininess in the images produced. In addition, the material’s high thermal conductivity and resistance to change at high temperatures would make these lenses able to better withstand intense, high-energy X-ray beams. Furthermore, diamond’s high refractive index means that the optical setup could be more compact than is the case for commonly-used metal and polymer lenses.

Compact stacks of lenses

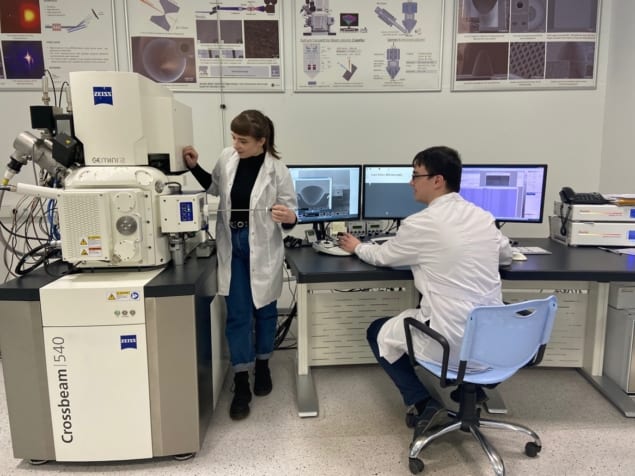

To create their high-quality lenses, the researchers used beams of ions less than 5 nm in diameter to carve out the lens shapes. This ion-beam lithography technique is commonly used to etch circuits and other high-resolution patterns onto 3D surfaces, and it enabled Medvedskaya and colleagues to produce sets of three diamond half-lenses with curvature radii of just 4.8 µm. They then assembled the lenses into compact stacks using micro-manipulation.

Images of the lenses obtained through scanning electron microscopy revealed that they each had a surface roughness no larger than 30 nm, and an overall curvature accurate to within just 200 nm. In tests at the PETRA-III synchrotron X-ray source at DESY in Germany, Medvedskaya and colleagues used their lenses to focus the hot, intense beams produced by the source down to resolutions of 100 nm.

With further research, the team say their approach could significantly improve the capabilities of modern synchrotron sources, enabling researchers to produce nanoscale-resolution images using a durable, highly compact apparatus. This would be particularly useful for phase-contrast imaging, which exploits differences in the refractive indexes of different materials to precisely differentiate between their structures. If the lens production technique becomes widely adopted, Medvedskaya and colleagues believe it could create diverse new opportunities for research in areas that require reliable shaping and conditioning of X-ray beams.